Preparation method of a three-dimensional ordered macroporous microelectrode

A technology of three-dimensional order and micro-electrodes, which is applied in the direction of micro-structure technology, micro-structure devices, and manufacturing micro-structure devices, etc., can solve the problems that micro-electrodes cannot achieve multi-functionality of electrodes, and achieve easy bending, high-efficiency utilization, and realization of energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

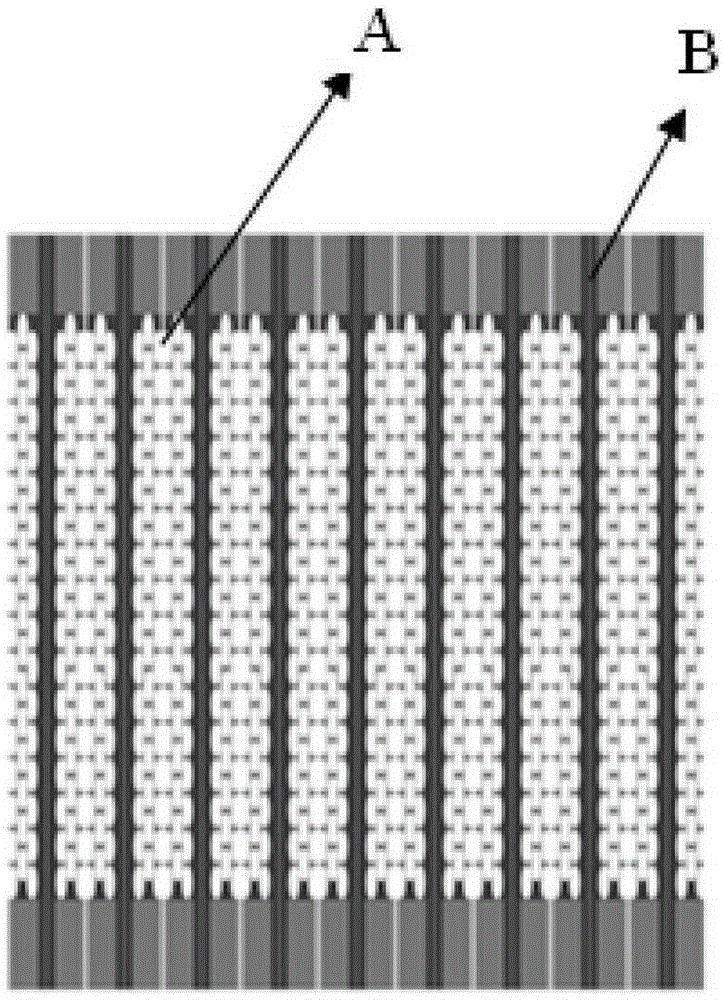

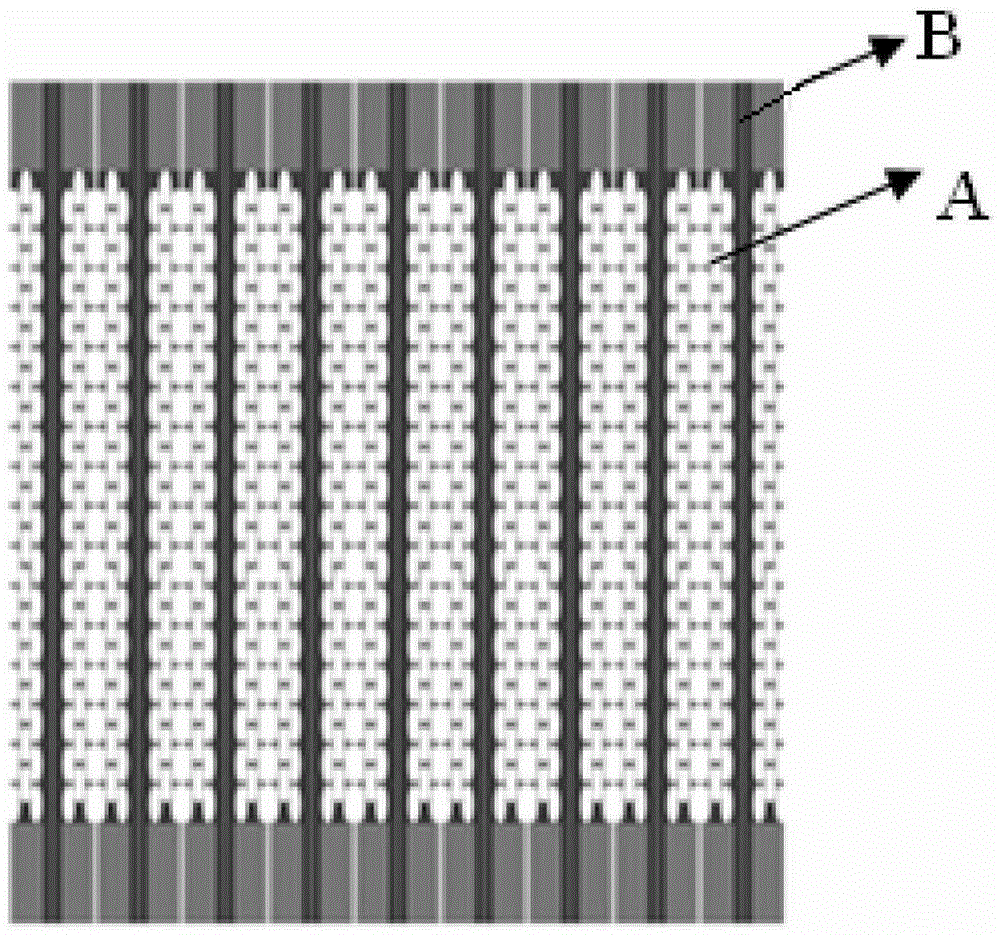

[0028] Specific embodiment one: the preparation method of a kind of three-dimensional ordered macroporous microelectrode of this embodiment is carried out according to the following steps:

[0029] 1. Select 10 μm ~ 100 μm metal wire as the substrate, and ultrasonically clean the metal wire with ethanol and ultrapure water for 15 ~ 30 minutes;

[0030] 2. Using deionized water as the dispersion solvent, ultrasonically disperse the polystyrene colloidal microspheres for 15-30 minutes to obtain a polystyrene colloidal microsphere emulsion with a volume fraction of 0.05%-0.3%;

[0031] Three, insert the metal wire of step 1 into the polystyrene colloidal microsphere emulsion obtained in step 2 at an angle of 80° to 90° with the liquid surface of the polystyrene colloidal microsphere emulsion obtained in step 2, and then place In a constant temperature incubator with a temperature of 55-65°C, after the dispersion solvent is completely volatilized, a polystyrene colloidal crystal t...

specific Embodiment approach 2

[0040] Embodiment 2: This embodiment differs from Embodiment 1 in that the metal wire described in step 1 is nickel wire, silver wire or copper wire. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0041] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the polystyrene colloidal microspheres described in step 3 have a diameter of 100-1000 nm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com