A fully automatic vacuum protective film labeling machine

A technology of protective film and labeling machine, applied in labeling, labeling, marking deformable materials, etc., can solve the problems of low production efficiency, high labor intensity, large randomness, etc., achieve precise positioning control, solve recruitment difficulties, and automate Program high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

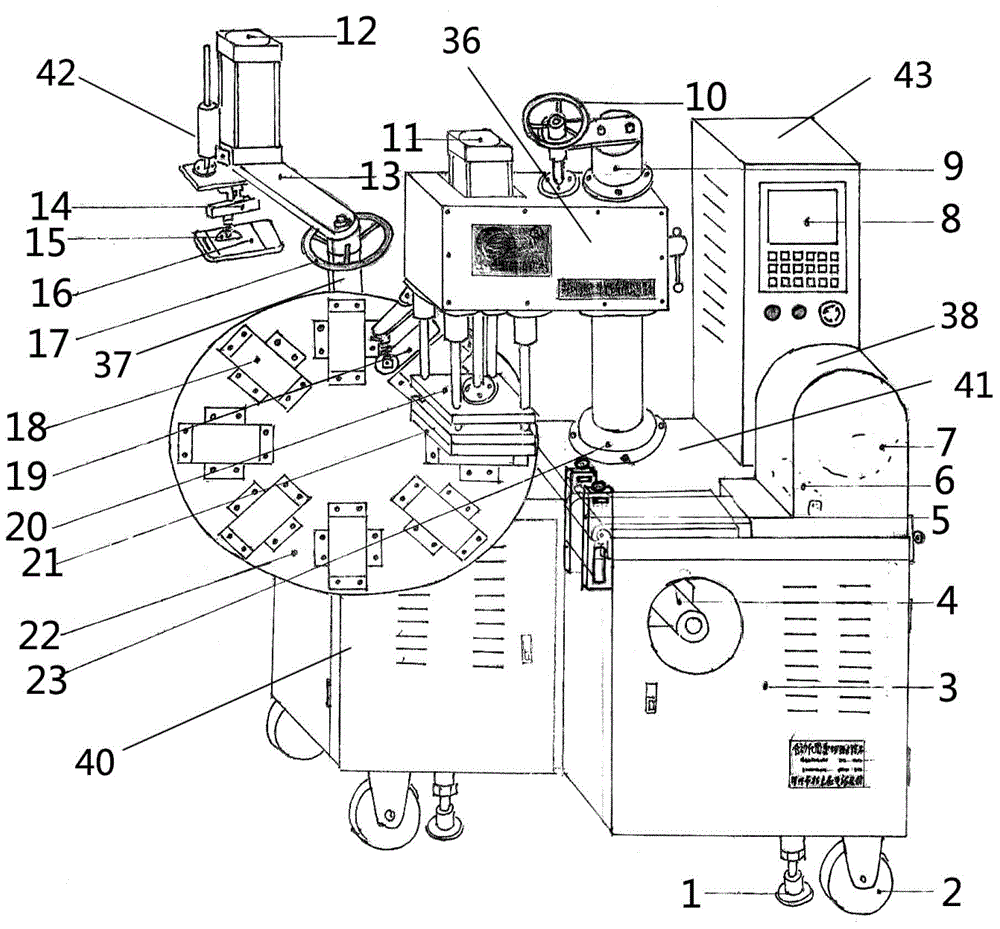

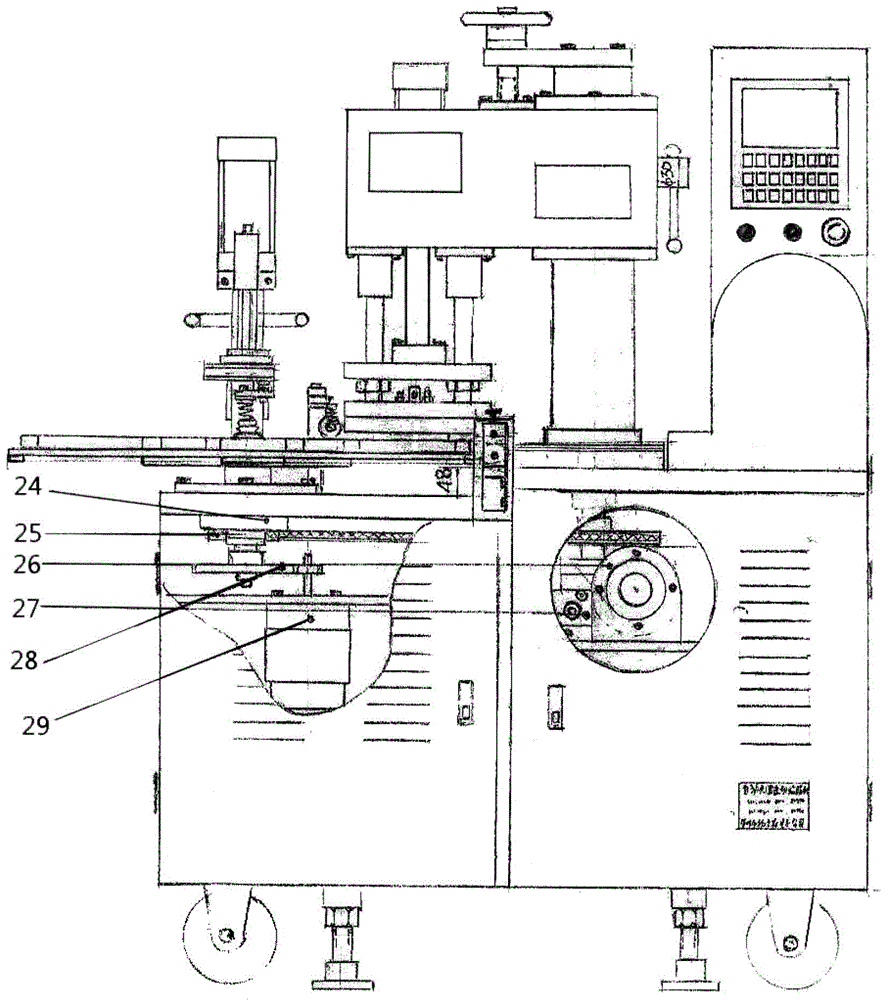

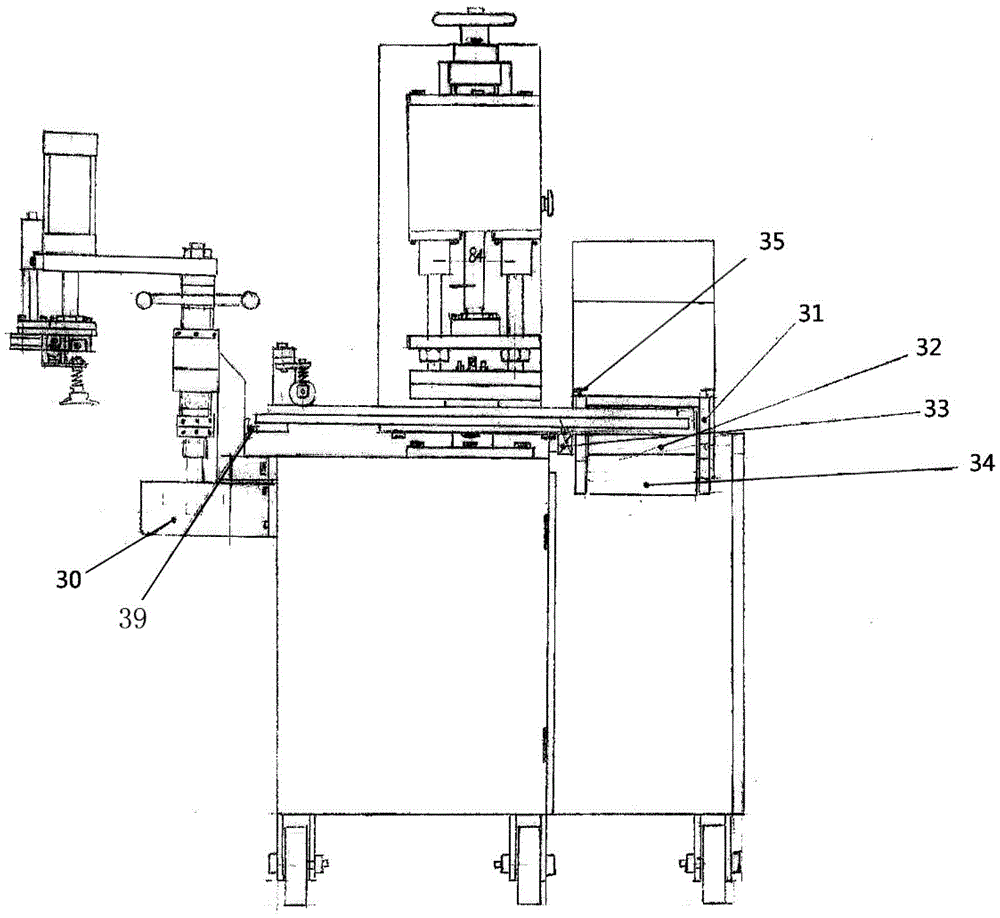

[0021] Such as figure 1 As shown, a fully automatic vacuum protective film labeling machine of the present invention includes a conveying device 38, a punching device 20, a disc 22, a jig 18, a soft spring wheel 19, a manipulator suction part swing device 42 and a PLC controller 43 , the conveying device 38 is located on the first electrical cabinet 39, the manipulator suction part swing device 42 and the PLC controller 43 are located on the third electric cabinet 41, and the manipulator suction part swing device 42 is installed on the synchronous wheel guard On the cover 30, the synchronous wheel shield 30 is fixed on the second electrical cabinet 40 by bolts, the disc 22 is located on the second electrical cabinet 40, the disc 22 is provided with a jig 18, and the spring The soft wheel 19 is arranged between the jigs 18, and the vacuum stick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com