Automatic ceramic base body microleakage detector and detection method thereof

A technology of ceramic seat and detection machine, which is applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, sorting, etc., which can solve the problems of unautomated production, helium pollution, and tweezers clamping For problems such as material damage, the effect of eliminating inspection and grading errors, reducing labor costs, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

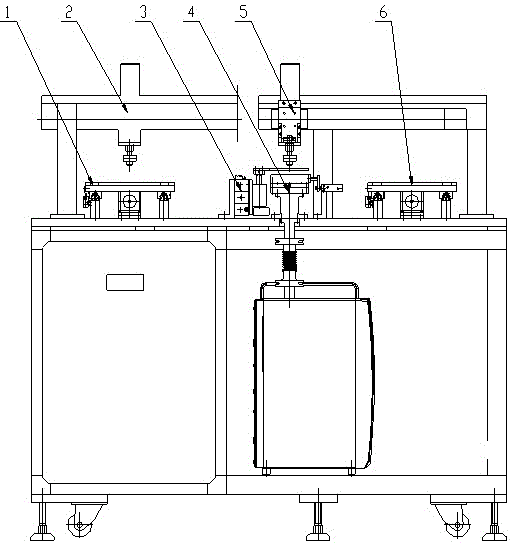

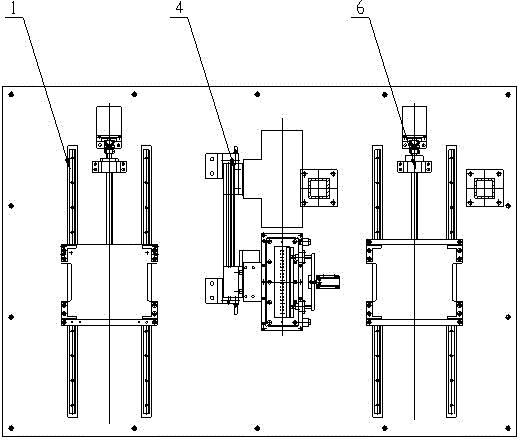

[0018] Such as figure 1 and figure 2 As shown, the present invention discloses an automatic detection machine for micro-leakage of a ceramic base, comprising a feeding part 1, a feeding manipulator 2, a box cover manipulator 3, a material receiving manipulator 5, a leak detection working part 4 and a material receiving part 6. The leak working part 4 includes a helium leak mass spectrometer, the feeding part 1 is used to place ceramic bases arranged in an array, the feeding manipulator 2 is used to move to the leak detection working part 4 after absorbing a discharge in the feeding part 1, and the box cover manipulator 3 It is used to move to the leak detection work part 4, and can form a sealed cavity with the leak detection work part 4. The helium leak mass spectrometer is used to detect the leakage of the ceramic base body, and the receiving mani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com