Composite material bracket body and preparation method thereof

A composite material and body technology, applied in the field of bracket body preparation, can solve the problems of metal material bracket body density, long processing cycle, poor weather resistance, etc., achieve stable structure and size, good production consistency, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1 A preparation technology for lamination and molding of the composite material bracket body of the storage and transportation launching tube

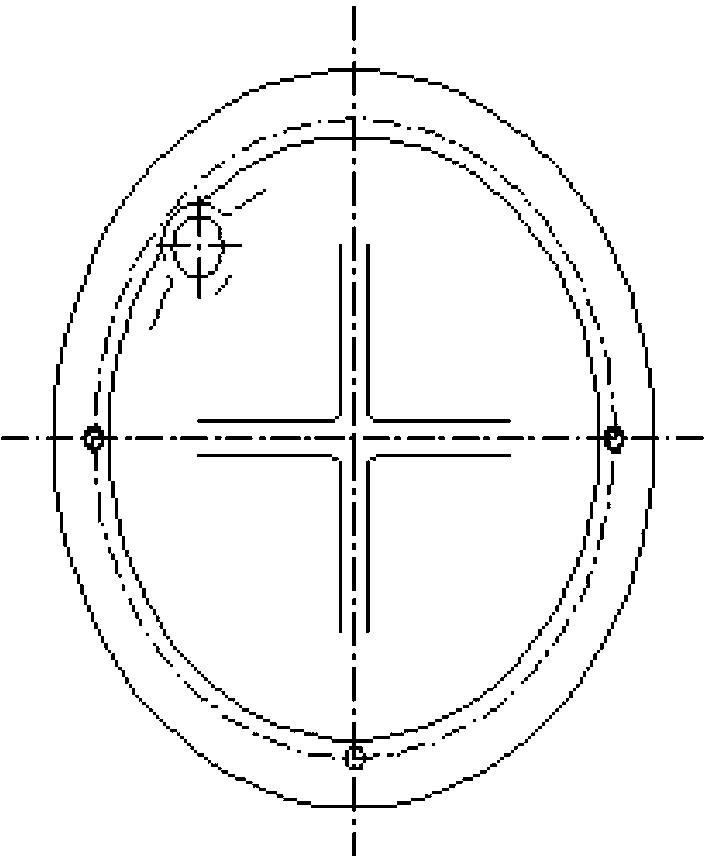

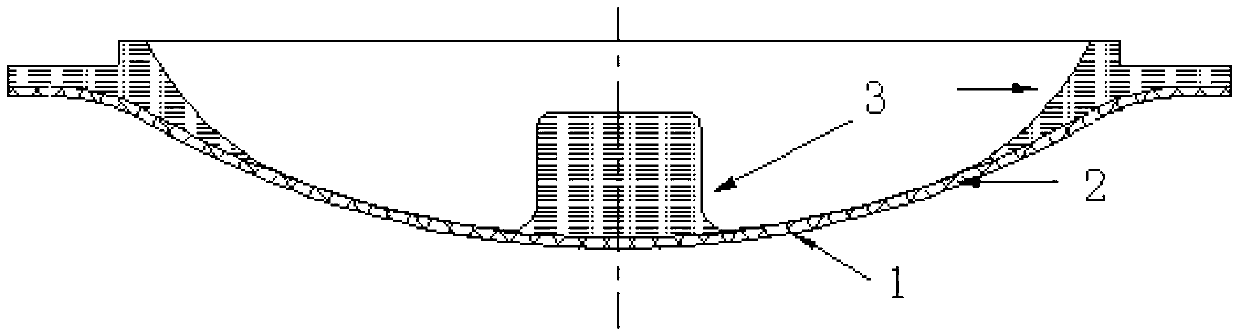

[0015] The maximum diameter of the main body of the storage and transportation launching tube composite material bracket formed by the present invention is about 678 mm, the diameter of the round table is about 555.5 mm, the width of the rib is about 30 mm, and the total height is about 100 mm. The composite bracket body of the storage and transportation launch tube is molded by hot pressing, and the structure and size of the bracket body are guaranteed by the mold. The specific preparation process is as follows:

[0016] The first step is to design and manufacture the mold, punch and die according to the shape of the bracket body. The mold adopts semi-overflow vertical parting structure, the guide system adopts built-in guide pillars, and the ejection blocks are designed at the four installation table positions of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com