Clamp holder for small enclosure frame in aircraft panel assembly

An aircraft wall panel and gripper technology, which is applied in aircraft assembly, aircraft parts, workpiece clamping devices, etc., can solve the problems of cumbersome control process of gripping small enclosures, complicated gripper structure, and increased hydraulic circuit, etc. Achieve the effect of reducing manual operation rate, simplifying clamping and positioning operations, and improving clamping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

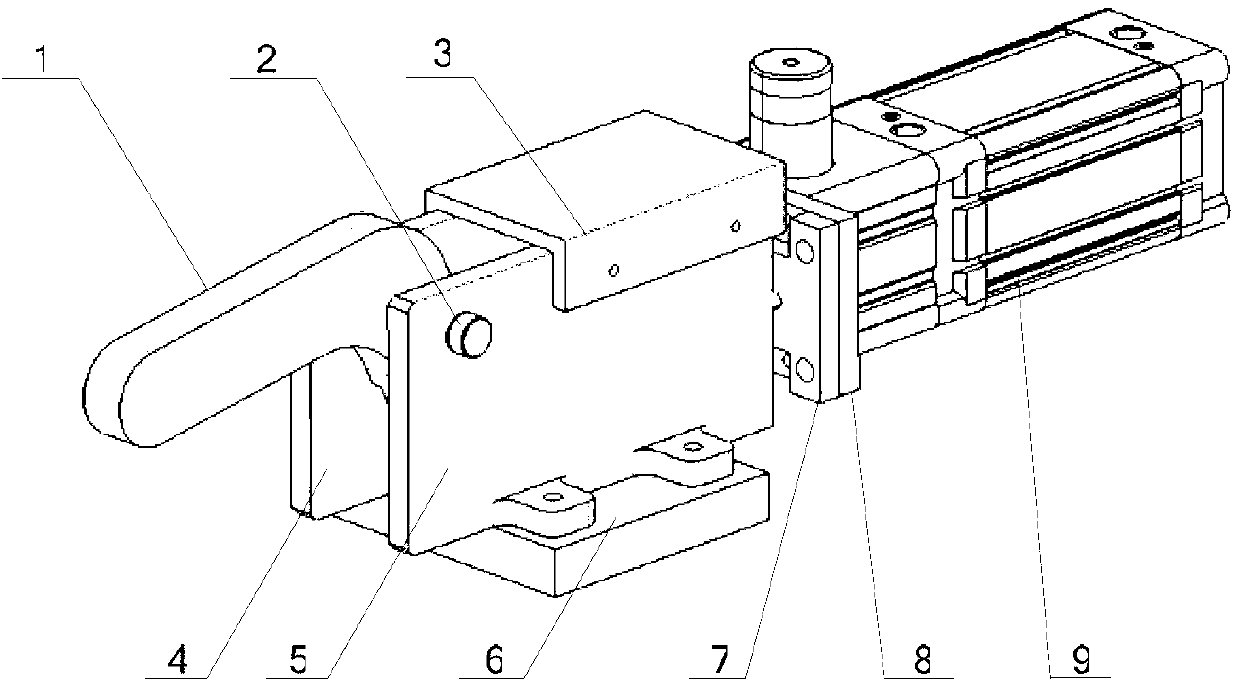

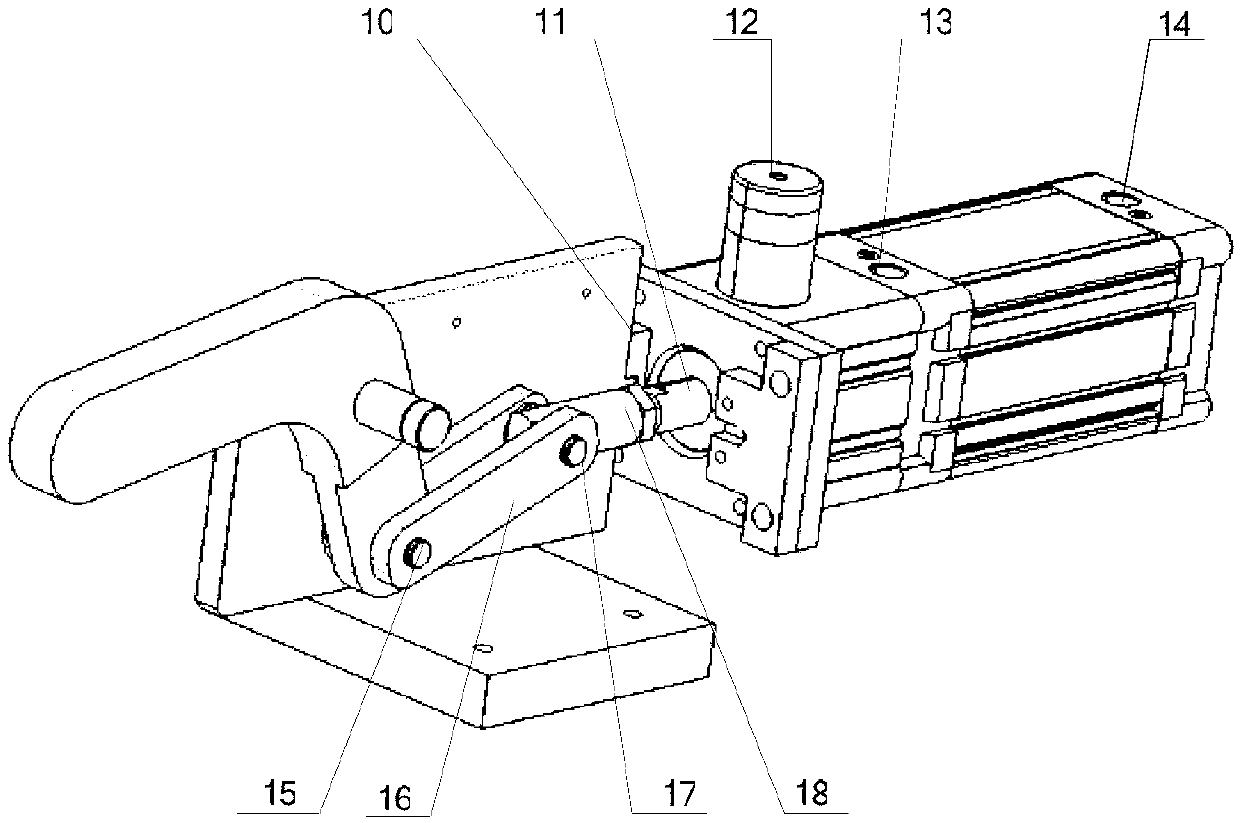

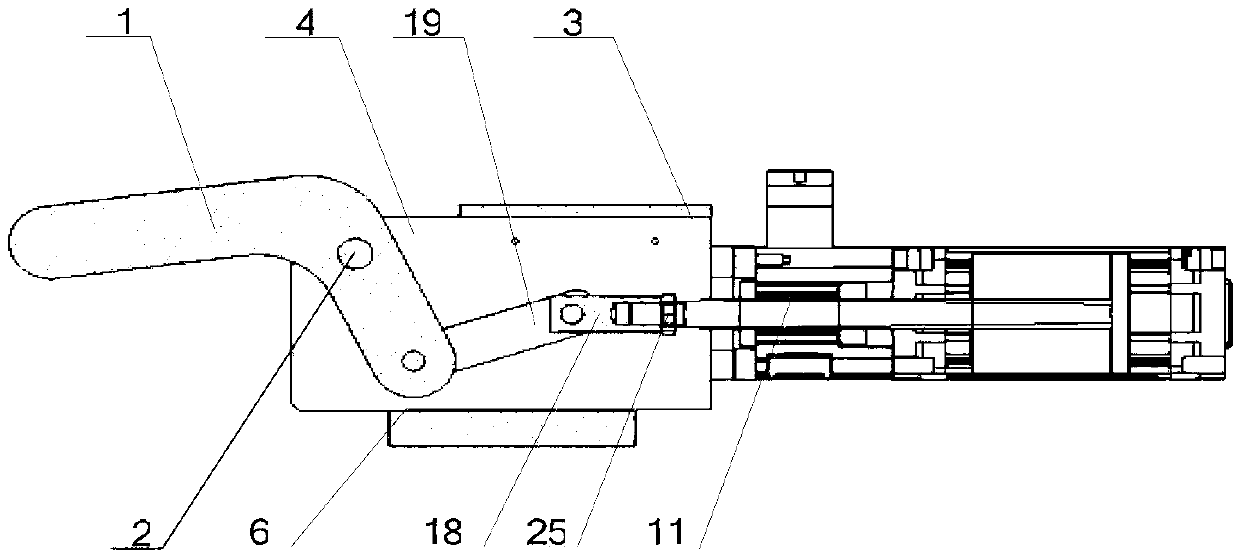

[0027] This embodiment is a clamper for assembling a small frame of an aircraft wall panel, and the pneumatic clamper is used to realize the clamping and positioning of the small frame during the panel assembly process.

[0028] refer to Figure 1-Figure 10 , the small frame holder of the present invention consists of a pressure bar 1, a pressure bar rotating shaft 2, a cover plate 3, a right fixed arm 4, a left fixed arm 5, a base 6, a left positioning block 7, a flange 8, a cylinder 9, and a right positioning Block 10, cylinder piston rod 11, locking mechanism 12, air inlet 13, air outlet 14, front connecting rod rotating shaft 15, left connecting rod 16, rear connecting rod rotating shaft 17, push rod 18, right connecting rod 19, connecting concave Groove 20, axle circlip groove 21, connecting lug 22, connecting flange 23, mating surface 24, internal screw hole 25 are formed.

[0029] The two fixed arms are rectangular parallelepiped structure, the right fixed arm 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com