Cable factory production line layout structure

A layout structure and production line technology, applied in the direction of cable/conductor manufacturing, conductor/cable supply device, circuit, etc., can solve the problems of increasing floor area, waste of resources, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

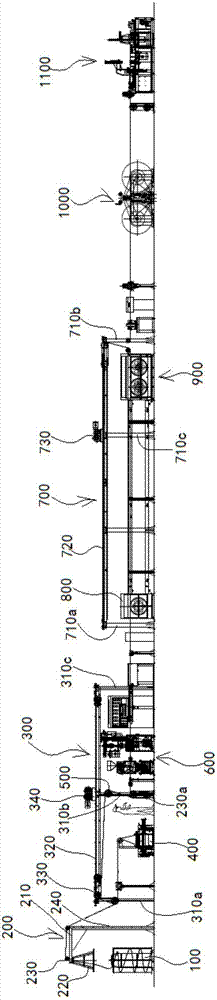

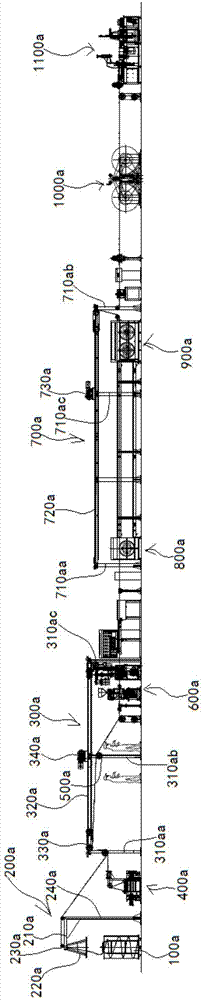

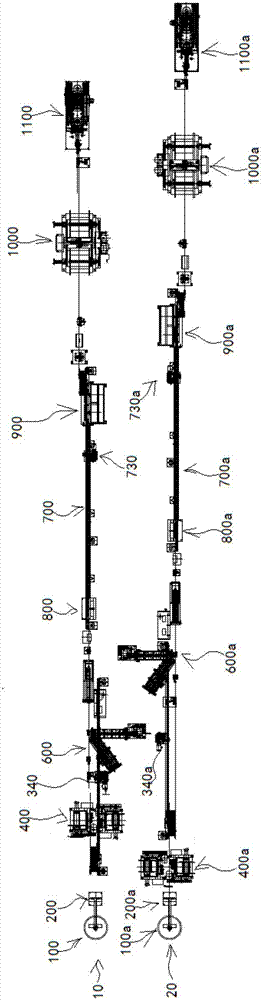

[0017] see Figure 1 to Figure 2 The layout structure of a cable factory production line shown includes at least one set of production lines, and the production lines include a first production line 10 and a second production line 20:

[0018] The first production line 10 comprises the barrel type pay-off rack 100 for the left mobile phone, and the first outlet frame 200 arranged on one side of the barrel type pay-off rack 100 for the left hand phone. One end is provided with the first outlet bucket 220, on the first outlet frame 200 is provided with turning guide wheel 230; One side of the column 310a is provided with a left mobile phone double-disc pay-off reel 400, and a turning guide wheel 330 is also provided at the corner of the column 310a and the guide rod 320; On the column 310b, a lower thread wheel 500 and a turning guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com