Rotary electrical device, bearing attachment and detachment tool, and bearing replacement method

A technology of rotating motors and fixtures, which is applied in the direction of rotating bearings, bearings, motors, etc., can solve the problems of unstable rotors, difficult to fix rotors, defects, etc., and achieve the effect of easy loading and unloading operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

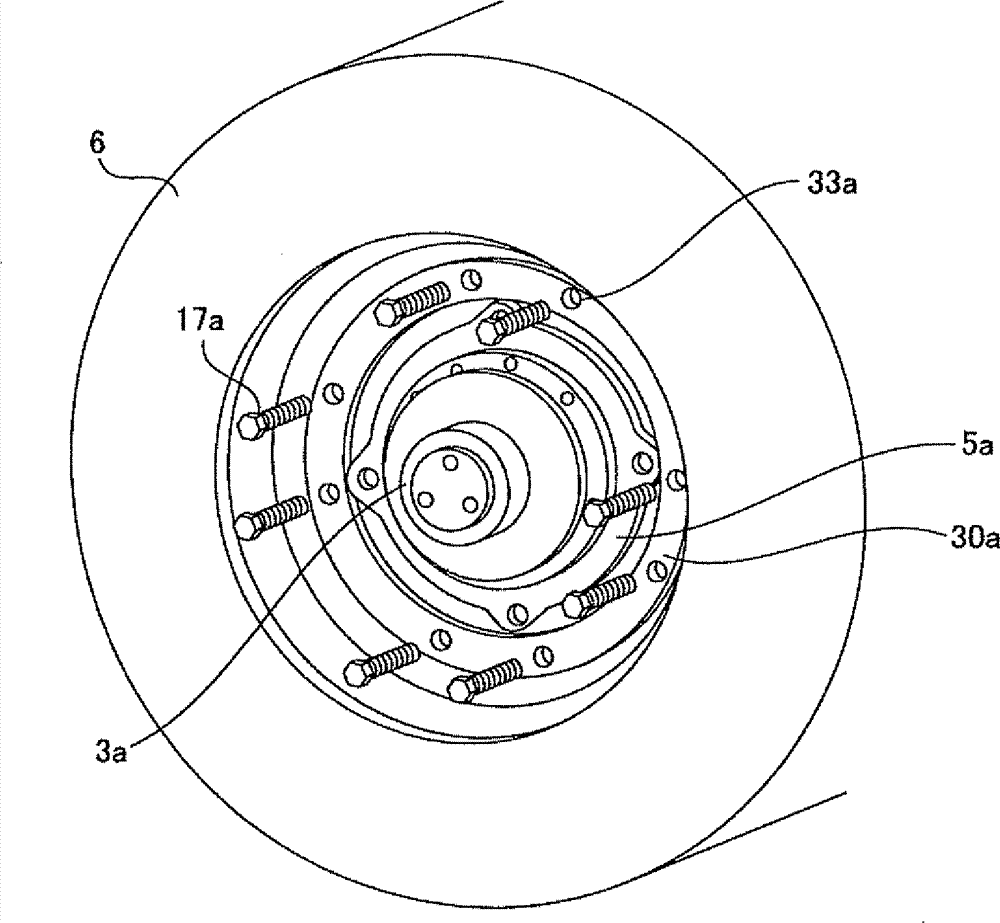

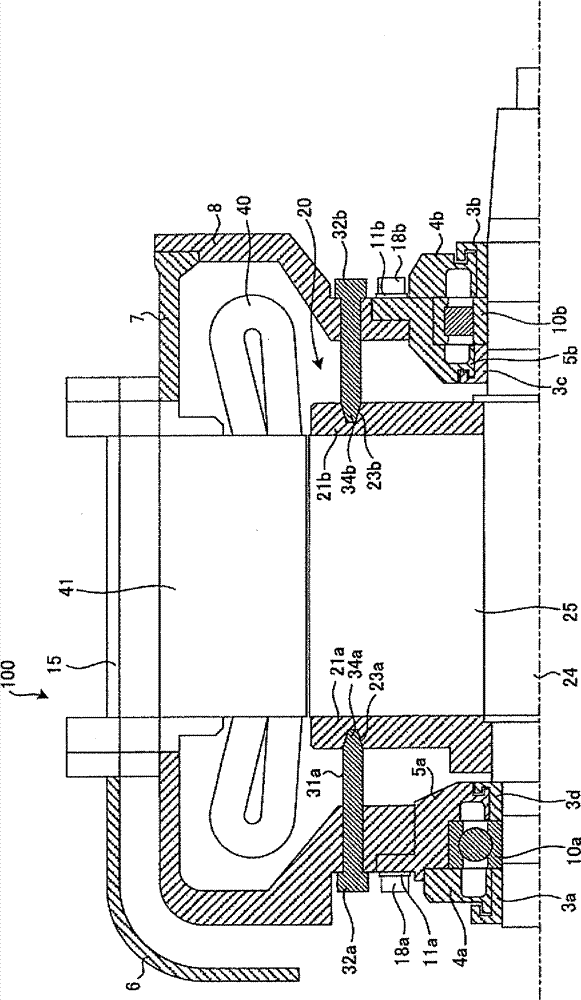

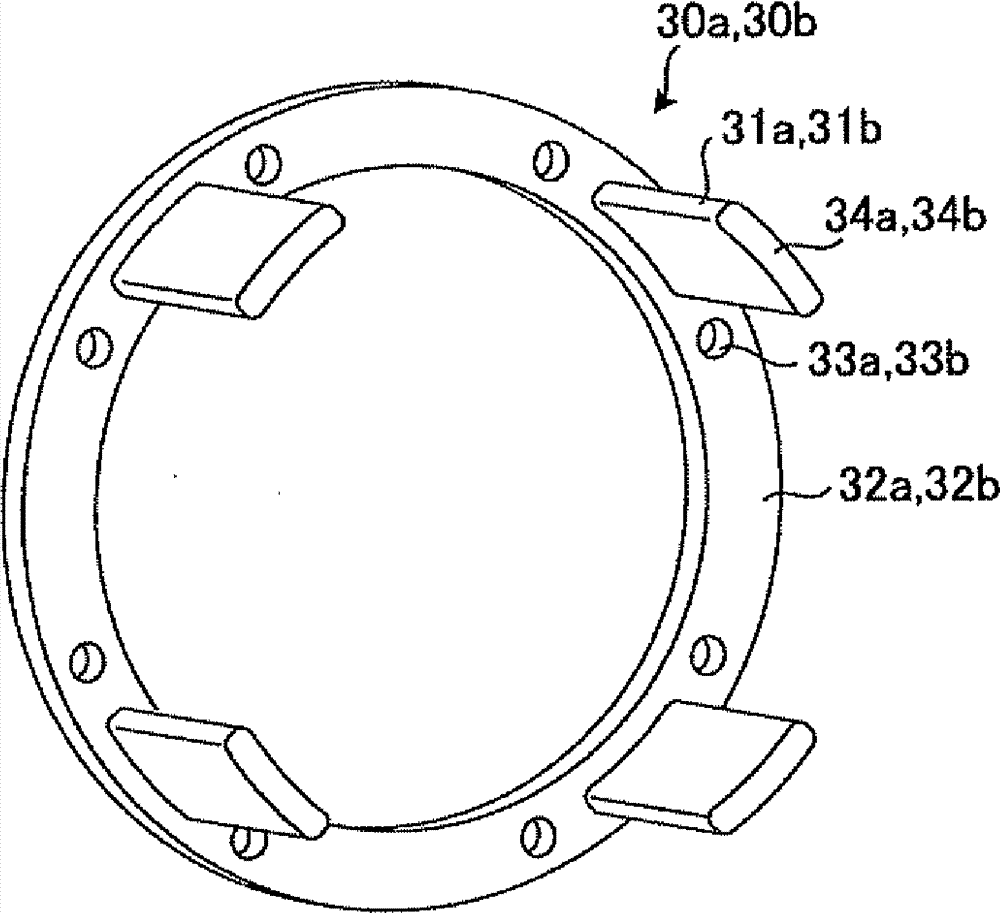

[0029] figure 1 is a longitudinal sectional view of the rotating electric machine 100 according to the embodiment of the present invention, figure 2 It is a figure which shows the structure of the ring-shaped jig 30. image 3 It is a perspective view of the rotor 20 shown centering on the iron core holding plate 21a on the opposite driving side, Figure 4 It is a drawing for explaining the shape of the recesses 23a, 23b formed in the core holder 21a on the opposite driving side or the core holder 21b on the driving side, and the shape of the ends of the rotor supporting parts (supporting parts) 31a, 31b.

[0030] In the following description, the figure 1 The structure of the rotating electrical machine 100 shown is described, after which, using figure 2 Carry out the description related to the ring-shaped clamps 30a, 30b, while using image 3 The structure of the rotor 20 will be described. In addition, in order to explain the structure of the rotating electric machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com