Method for preparing ZnO/Ag nanometer composite materials in room temperature

A nano-composite material and room temperature technology, applied in the field of preparing ZnO/Ag nano-composite materials, can solve problems such as harsh conditions and complex processes, and achieve the effects of easy control of the process, simple process, and easy control of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

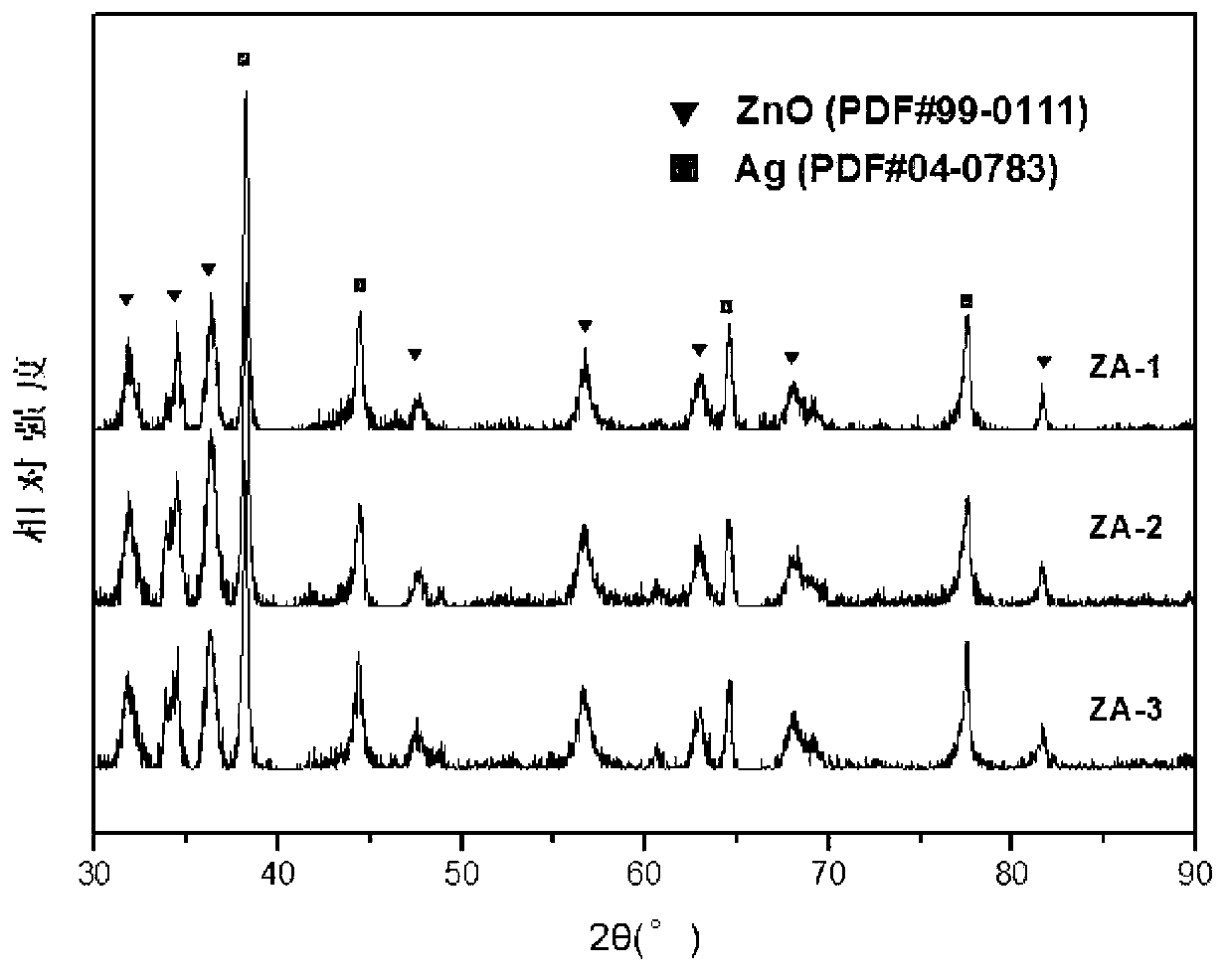

Image

Examples

Embodiment 1

[0019] (1) Take 0.8g of nano-zinc powder that has been ground for 5 hours, disperse it in 34ml (water:cyclohexane=17:1) dispersion system, and shake evenly;

[0020] (2) At room temperature, place the reaction system in (1) in a 40KHz sonicator for 6 hours, during which time take out the Erlenmeyer flask and shake vigorously for 30 seconds every 15 minutes; after the treatment, take out the upper milky white suspension for later use;

[0021] (3) Add dropwise 0.1mol / L AgNO to the milky white suspension in (2) 3 solution until the brown-black flocs no longer increase;

[0022] (4) Centrifuge to separate the brown-black precipitate, and wash it with distilled water to remove the Ag inside + and NO 3 - For impurity ions, repeat this step, and finally place the precipitate in a clean reagent bottle;

[0023] (5) Add absolute ethanol to the reagent bottle obtained in step (4), shake to disperse the precipitate evenly, and place it in an ultrasonic machine for ultrasonic dispers...

Embodiment 2

[0026] (1) Get 1.0g of nano-zinc powder ground for 5h, disperse it in 40ml (water:cyclohexane=19:1) dispersion liquid, shake evenly;

[0027] (2) At room temperature, place the reaction system in (1) in a 40KHz sonicator for 8 hours. During this period, take out the Erlenmeyer flask and shake vigorously for 30 seconds every 15 minutes; after the treatment, take out the upper milky white suspension for later use;

[0028] (3) Add a certain amount of 0.1mol / L AgNO dropwise to the milky white suspension in (2) 3 solution until the brown-black flocs no longer increase;

[0029] (4) Centrifuge to separate the brown-black precipitate and wash it with distilled water to remove the Ag inside + and NO 3 - For impurity ions, repeat this step, and finally place the precipitate in a clean reagent bottle;

[0030] (5) Add absolute ethanol to the reagent bottle obtained in step (4), shake to disperse the precipitate evenly, and place it in an ultrasonic machine for ultrasonic dispersion...

Embodiment 3

[0033] (1) Take 1.2g of nano-zinc powder that has been ground for 5 hours, disperse it in 44ml (water:cyclohexane=21:1) dispersion system, and shake it evenly;

[0034] (2) At room temperature, place the reaction system in (1) in a 40KHz sonicator for 10 hours. During this period, take out the Erlenmeyer flask and shake vigorously for 30 seconds every 15 minutes; after the treatment, take out the upper milky white suspension for later use;

[0035] (3) Add a certain amount of 0.1mol / L AgNO dropwise to the milky white suspension in (2) 3 solution until the brown-black flocs no longer increase;

[0036] (4) Centrifuge to separate the brown-black precipitate and wash it with distilled water to remove the Ag inside + and NO 3 - For impurity ions, repeat this step, and finally place the precipitate in a clean reagent bottle;

[0037] (5) Add absolute ethanol to the reagent bottle obtained in step (4), shake to disperse the precipitate evenly, and place it in an ultrasonic machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com