Method for reducing the thickness of oxide scale on the surface of hot-rolled steel plate

A technology for surface oxidation and hot-rolling of steel sheets, applied in metal rolling, temperature control, metal rolling, etc., can solve the problem of reducing the heating temperature or holding time of the slab, affecting the uniformity of the structure in the cooling process, and unfavorable alloying elements uniformity, etc. To solve the problem, to achieve the effect of reducing the amount of acid used for pickling, reducing the time of pickling, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The roughing mill is a four-roller reversible roughing unit with vertical rollers. Its maximum rolling pressure is 5000t, and the capacity of the main drive motor is 2×7500kW. Width 1562mm.

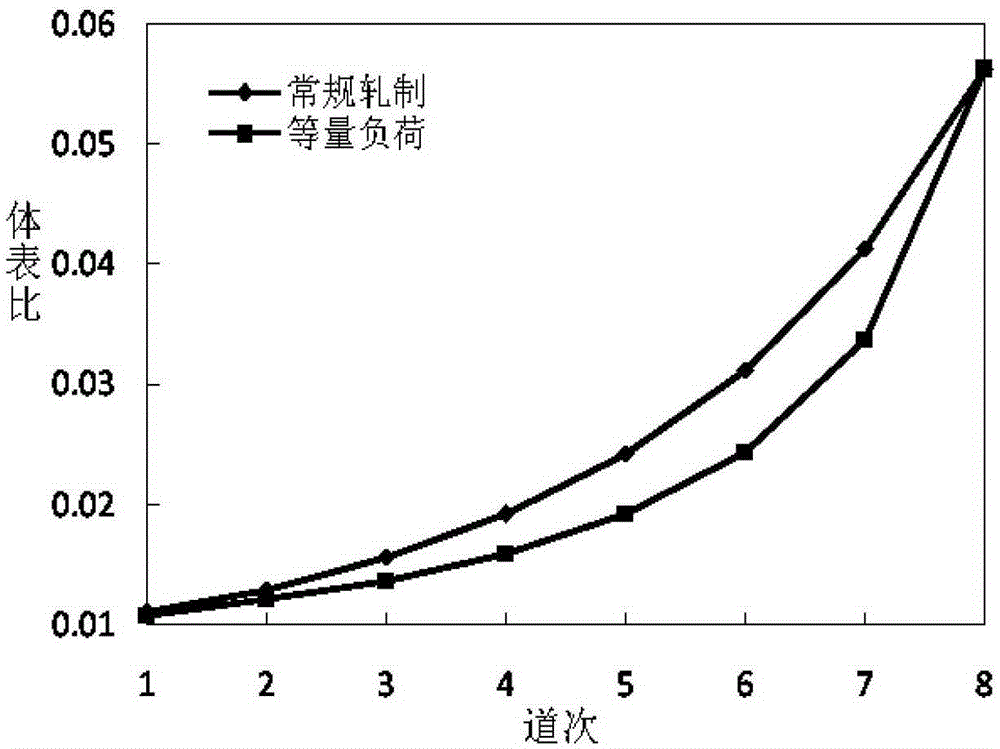

[0046] First, the continuous casting slab is dephosphorized with vertical rolls; then rough rolling is carried out, the rough rolling pass is set to 8 passes, the reduction of each pass is controlled to be 25.11mm, and the rough rolling total deformation is 84.6%. Embodiment Table 1 shows the rolling data of the continuous casting slab of 1 in each pass.

[0047] Another example of rolling with the conventional rough rolling method is set as the comparative example 1 of embodiment 1, at first the continuous casting slab is dephosphorized with vertical rolls; Considering the biting ability and thickness fluctuation in the first and second passes, the reduction amount is slightly smaller, and the reduction amount in the third pass is the largest, and then the reduction amount of eac...

Embodiment 2

[0055] The rough rolling mill is a four-high reversing mill with a maximum rolling pressure of 58854kN, a maximum rolling torque of 5493kJ, and a main drive motor with a capacity of 2×4600kW; 2600mm.

[0056] First, the continuous casting slab is subjected to conventional dephosphorization; then rough rolling is carried out, and the rough rolling pass is set to 7 passes. The reductions are all 20.00mm, and the total rough rolling deformation is 70%.

[0057] In addition, an example of rolling with conventional rough rolling method is set as the comparative example 2 of embodiment 2. At first, the conventional dephosphorization of the continuous casting slab is carried out; Biting ability and thickness fluctuate, the amount of reduction is slightly smaller, and the amount of reduction in the second pass is the largest, and then the reduction amount of each pass is controlled to decrease from pass to pass, and the total deformation of rough rolling is guaranteed to be 70%. The...

Embodiment 3

[0065] The roughing mill is a four-roller reversible roughing unit with vertical rollers, its maximum rolling pressure is 5000t, and the capacity of the main drive motor is 2×7500kW; Width 1562mm.

[0066] First, the continuous casting slab is dephosphorized with a vertical roll; then rough rolling is carried out, and the rough rolling pass is set as 7 passes, the reduction of each pass is controlled to be 25.6mm, and the rough rolling total deformation is 80%. Embodiment The rolling data of the continuous casting slab of 3 in each pass are shown in Table 5.

[0067] In addition, an example of rolling with conventional rough rolling method is set as the comparative example 3 of embodiment 3, at first the continuous casting slab is dephosphorized with vertical rolls; Considering the biting ability and thickness fluctuation in the first and second passes, the reduction amount is slightly smaller, and the reduction amount in the third pass is the largest, and then the reduction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com