Composite solution for sulphur dioxide absorption in membrane separation

A compound solution and sulfur dioxide technology, applied in the field of flue gas desulfurization, liquid-gas separation, to achieve the effect of easy purchase, small foaming and high desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

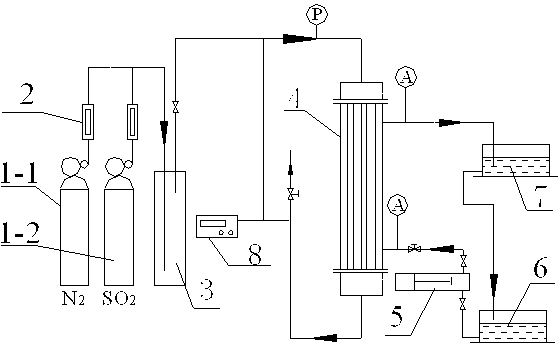

[0025] A performance evaluation method for the application of composite solutions in membrane contactors for sulfur dioxide membrane absorption.

[0026] Operating conditions: room temperature (19-22°C), mixed gas pressure 0.11MPa, membrane mass transfer area 1.5 m 2 , the gas flow rate is 0.5-2 L / min, and the liquid flow rate is 200-500mL / min.

[0027] Such as figure 1 shown, respectively from N 2 Gas cylinder 1-1 and SO 2 After the gas in the gas cylinder 1-2 is measured by the gas quality control instrument 2, it enters the mixing and stabilizing tank 3 to form SO containing 0.1%-0.6% (volume percentage). 2 Mixed gas, the mixed gas after the air flow is stabilized enters the membrane contactor 4, and the SO in the mixed gas 2 It diffuses to the other side of the membrane through the membrane pores, is absorbed by the composite desulfurizer, that is, the aforementioned composite solution in the present invention, enters the liquid phase, and the absorbed gas phase is rel...

Embodiment 2

[0037] The composite solution used to absorb sulfur dioxide in the mixed gas is an aqueous solution of potassium lactate / sodium lactate and glycinate, the total concentration of potassium lactate / sodium lactate and glycinate in the aqueous solution is 0.1~3.6mol / L, and the concentration of potassium lactate / sodium lactate and glycinate The molar ratio is 1:(0.5~2.2).

[0038] In this embodiment, the glycinate may be sodium glycinate, potassium glycinate or a mixture of sodium glycinate and potassium glycinate.

[0039] The performance evaluation method in Example 1 is used for detection.

[0040] Process operating conditions: room temperature, gas phase pressure 0.11MPa, mixed gas SO 2 Content 0.1%-0.6% (volume percentage), membrane mass transfer area 1.5m 2 , gas velocity: 0.5-2L / min, liquid velocity: 200-500mL / min.

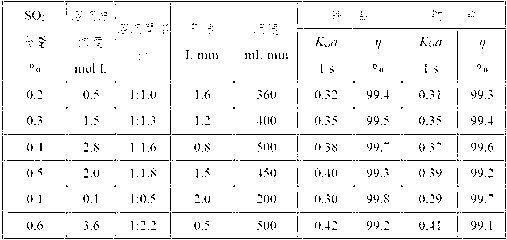

[0041] The performance evaluation results of various desulfurizers under various conditions are shown in Table 1.

[0042] Table 1 Performance evaluation re...

Embodiment 3

[0047] The composite solution used to absorb sulfur dioxide in the mixed gas is an aqueous solution of potassium lactate / sodium lactate and β-alanine salt, the total concentration of potassium lactate / sodium lactate and β-alanine salt in the aqueous solution is 0.1~3.6mol / L, The molar ratio of potassium lactate / sodium lactate to β-alanine salt is 1: (0.5~2.2).

[0048] In this embodiment, the β-alanine salt can be sodium β-alanine, potassium β-alanine or a mixture of sodium β-alanine and potassium β-alanine.

[0049] The performance evaluation method in Example 1 is used for detection.

[0050] Process operating conditions: room temperature, gas phase pressure 0.11MPa, mixed gas SO 2 Content 0.1%-0.6% (volume percentage), membrane mass transfer area 1.5m 2 , gas velocity: 0.5-2L / min, liquid velocity: 200-500mL / min.

[0051] The performance evaluation results of various desulfurizers under various conditions are shown in Table 2.

[0052] Table 2 Performance evaluation resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com