Water purification device liquid level control system

A technology for water purification device and liquid level control, applied in liquid level control, control/regulation system, non-electric variable control, etc., can solve problems such as electrode corrosion, difficulty in monitoring electrical signals, and safety of electricity use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

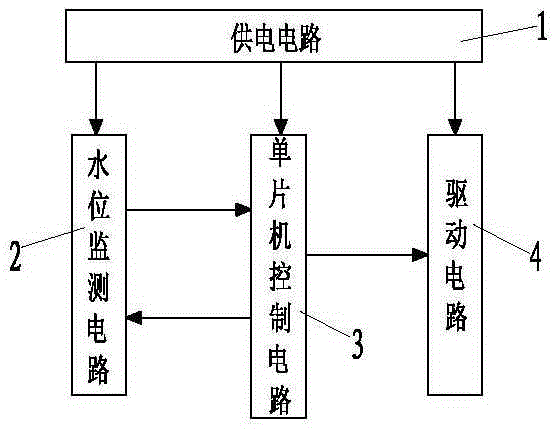

[0030] Such as figure 1 As shown, the liquid level control system of the water purification device of the present invention comprises:

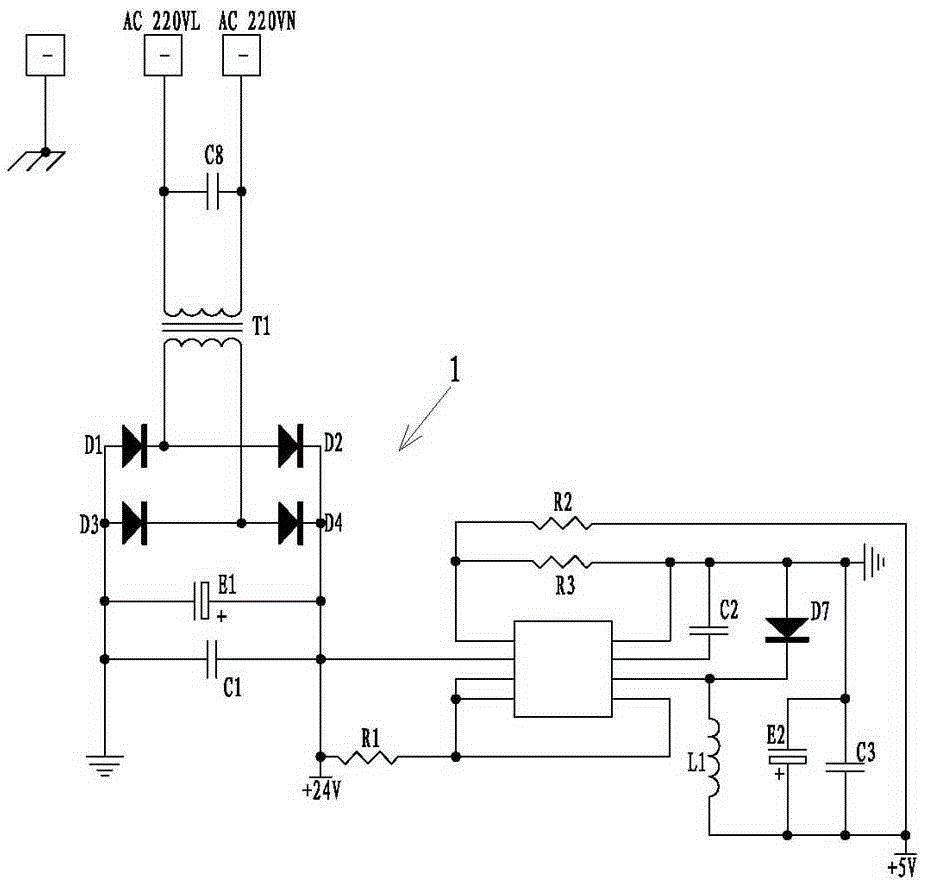

[0031] combine figure 2 As shown, power supply circuit 1: It is composed of a transformer rectifier filter circuit and a step-down regulator circuit, which is connected to 220V, 50Hz AC domestic electricity, through transformer T1, bridge rectifier circuit D1, D2, D3, D4, And capacitor filtering, to obtain approximately 24V DC, which is used to provide a voltage stabilizing circuit for the water level monitoring circuit 2 and the drive circuit 4, and the rectified 24V DC passes through the current IC and DC-DC converter 34063A to chop the 24V D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com