Magnetic bevel gear for non-contact type space crossing driving and manufacturing method and application thereof

A cross-drive, non-contact technology, applied in the direction of transmission, belt/chain/gear, components with teeth, etc., can solve the problems of inability to realize large torque transmission, small rotation radius of transmission magnetic gear, etc., and achieve simple structure , Small vibration, easy to make effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

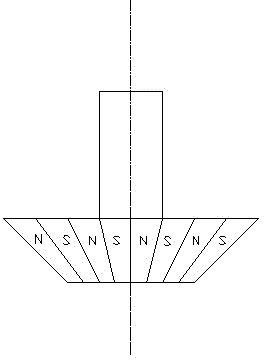

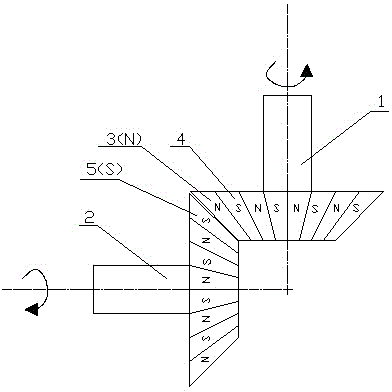

[0018] See figure 1 , The magnetic bevel gear for non-contact spatial cross transmission includes a magnetic bevel gear, which is characterized by:

[0019] 1) Its magnetic poles are evenly distributed on the tapered surface of the magnetic bevel gear with the S pole and the N pole interval,

[0020] 2) The magnetic poles are arranged circumferentially in a trapezoidal shape,

[0021] 3) The arrangement of all magnetic poles forms a smooth and complete cone.

Embodiment 2

[0023] This embodiment is basically the same as the first embodiment. The special feature is that the entire tapered shaft end is a bonded compact of neodymium iron boron, and its magnetic pole is formed by a radial multi-pole magnetizing structure on the external surface of the bonded compact magnetic pole.

Embodiment 3

[0025] The method for manufacturing magnetic bevel gears for non-contact spatial cross transmission is used for manufacturing according to the claims

[0026] The magnetic bevel gear for non-contact spatial cross transmission is characterized in that the tapered shaft end of the magnetic bevel gear is made of neodymium iron boron permanent magnet material through bonding and pressing, and then the tapered surface is obtained by radial multi-pole magnetization magnetic pole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com