A dual-discharge high-pressure manifold for fracturing

A technology of high-pressure manifolds and pressure relief pipes, which is applied in the fields of mining fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of reduced water power efficiency of pump trucks, single structure and function, and reduced suction performance, etc., to achieve protection The effects of safe construction work, firm support positioning, and improved suction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

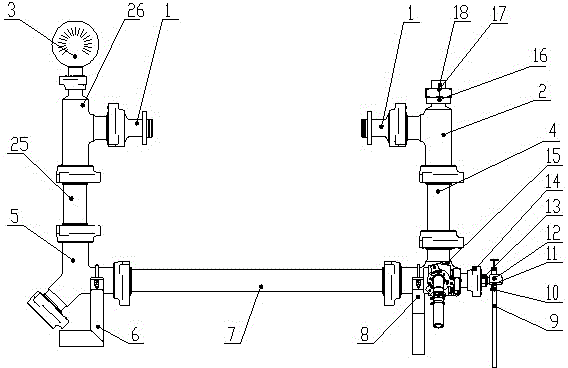

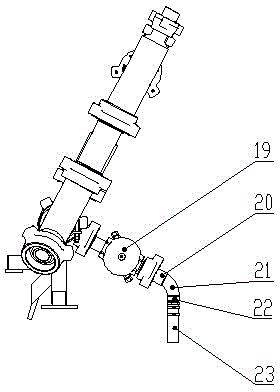

[0017] Attached below figure 1 and 2 , the present invention will be further described.

[0018] A dual-discharge high-pressure manifold for fracturing includes a discharge flange assembly 1, a T-shaped tee-2, a Martin Deck meter 3, a double-male variable-diameter joint-4, a Y-shaped tee 5, and a Y-shaped tee bracket 6. Integral double male straight pipe assembly 7, four-way joint bracket 8, four-way joint assembly 15, conversion joint 16, sensor joint 17, pressure sensor 18, T-shaped tee two 26, double male reducing joint two 25, by Plug valve 19, male union 20, elbow 21, pipe clamp 22 and steel wire reinforced steam pipe 23 form pressure relief manifold Ⅰ, which consists of steam cloth hose 9, stainless steel hose clamp 10, hose joint 11, needle valve 12 1. The male union needle valve joint 13 and the special-shaped nut 14 form the pressure relief manifold II, wherein the plug valve 19 in the pressure relief manifold I is connected with the male union 20, and the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com