Construction method for hanging part of anti-collision guardrail on expressway

A technology of anti-collision guardrails and construction methods, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problems that formwork tie bars cannot be reused, no published patent documents have been found, and the level of formwork is not easy to control. It achieves simple structure, Ease of processing and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

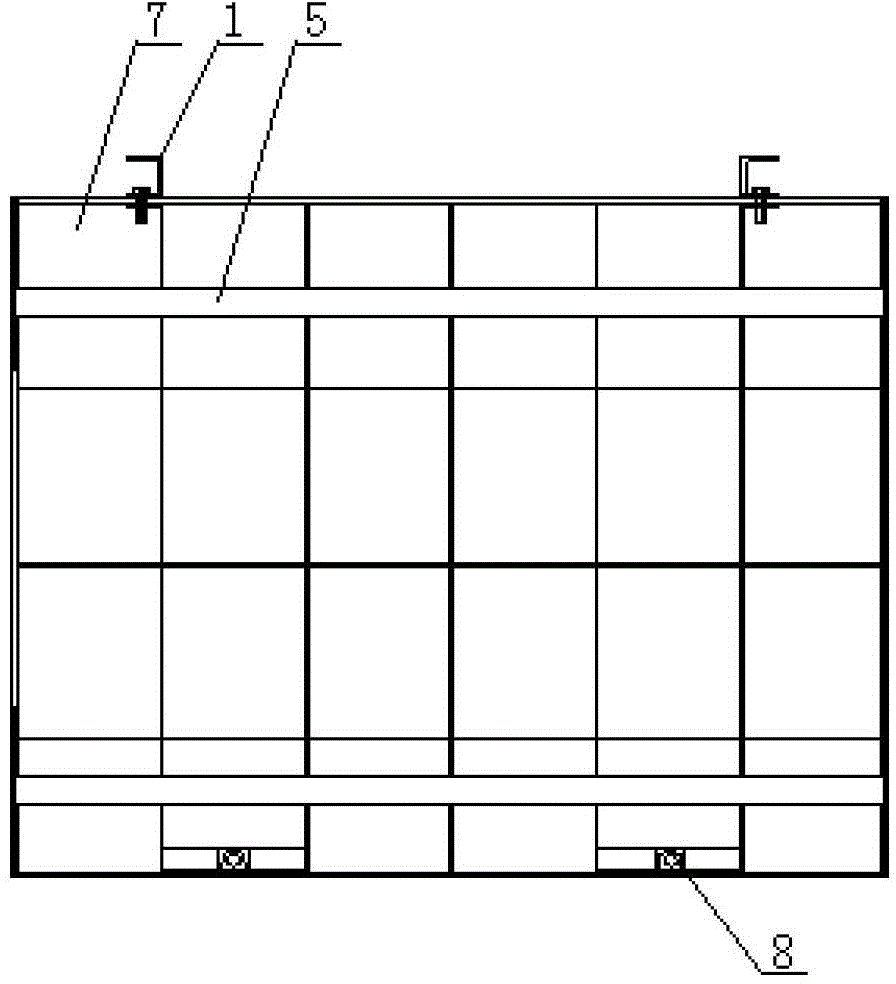

[0022] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0023] A construction method for the suspended part of the anti-collision guardrail of the expressway, the steps are:

[0024] ⑴Use a total station in advance to accurately stake out the inner edge of the suspended part 2 of the anti-collision guardrail. On the straight line section, you can place a point every 5m in the vertical direction, and on the curved section, you can encrypt it to a point every 2m in the vertical direction. Finally, use The ink line connects each lofting point bullet line as the installation edge line of the inner formwork 7;

[0025] (2) According to the above-mentioned marks, bury the ground anchor steel bar 11 on the top plate of the prefabricated box girder 12, fix a horizontal steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com