Hollow structure indium oxide nanometer fiber preparation method

A nanofiber, indium oxide technology, applied in the fiber type, fiber treatment, spinning solution preparation and other directions, can solve the problems that have not been reported, and achieve the effects of high yield, increased specific surface area, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

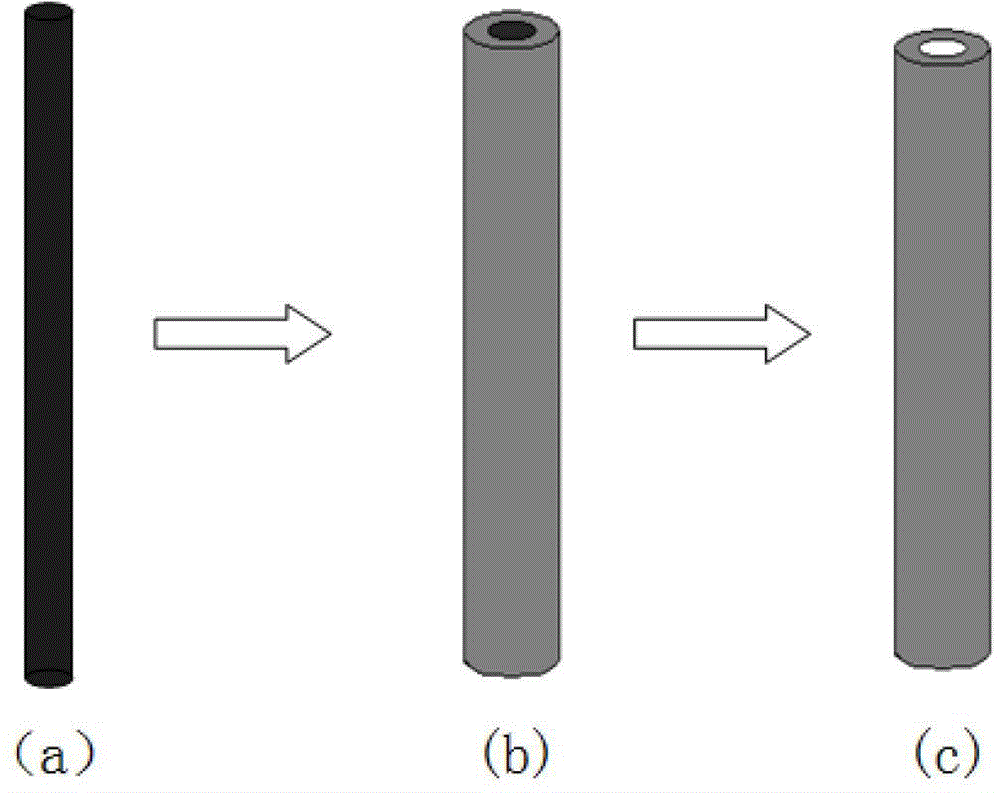

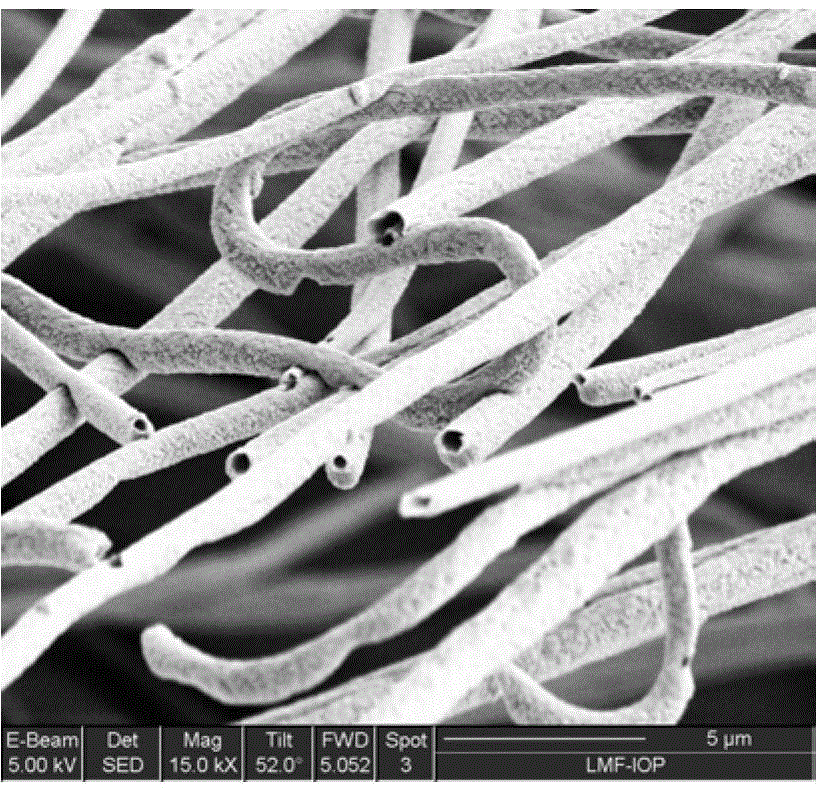

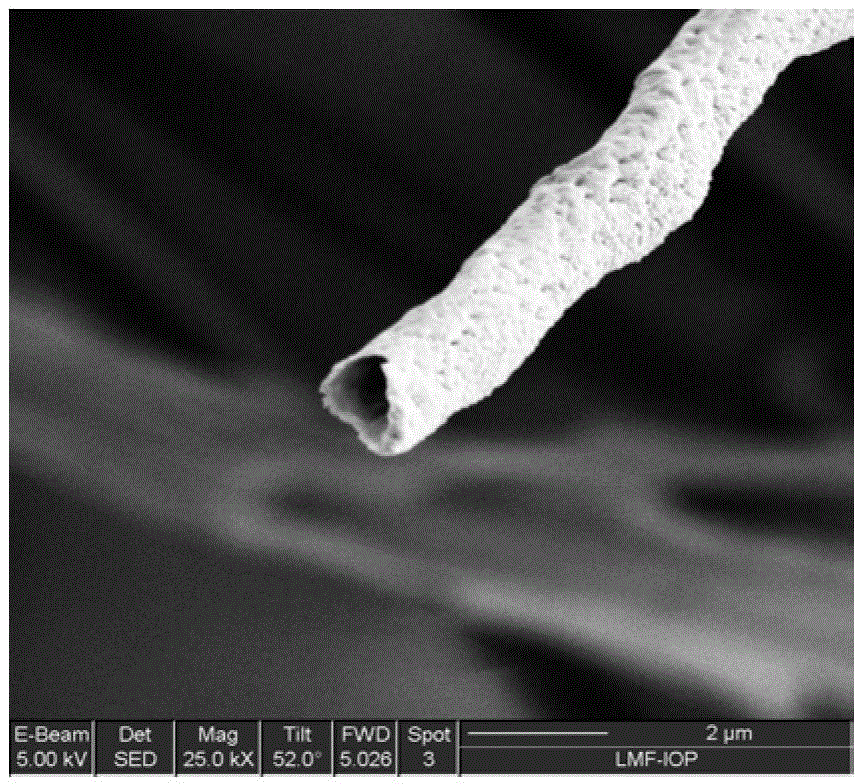

[0015] In this example, the method of combining electrospinning and magnetron sputtering technology is used to prepare hollow structure indium oxide nanofibers. The specific steps include preparing polyvinylidene fluoride (PVDF) nanofibers, wrapping indium oxide and high temperature sintering to remove PVDF. step:

[0016] (1) Preparation of polyvinylidene fluoride (PVDF) nanofibers: select a conventional electrospinning device suitable for the spinning solution of the present invention, select a preparation occasion where the ambient temperature is 20°C and the humidity is 25%RH, and use an electronic balance Weigh 2.0 g of polyvinylidene fluoride (PVDF), dissolve it in a mixed solvent composed of N,N dimethylformamide (DMF, 4.0 g) and acetone (4.0 g) at a mass ratio of 1:1, and Stir magnetically in a water bath at 60-80°C for 2-5 hours to obtain a uniform and transparent PVDF solution; then use the electrospinning device to perform electrospinning in the air according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com