Preparation method of polydiacetylene vesicle with excellent performance

A technology of polydiacetylene and diacetylene, which is applied in the field of preparation of polydiacetylene vesicles, can solve problems such as poor mechanical properties, uneven dispersion, agglomeration and precipitation, etc. Uniform distribution and obvious effect of hollow structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

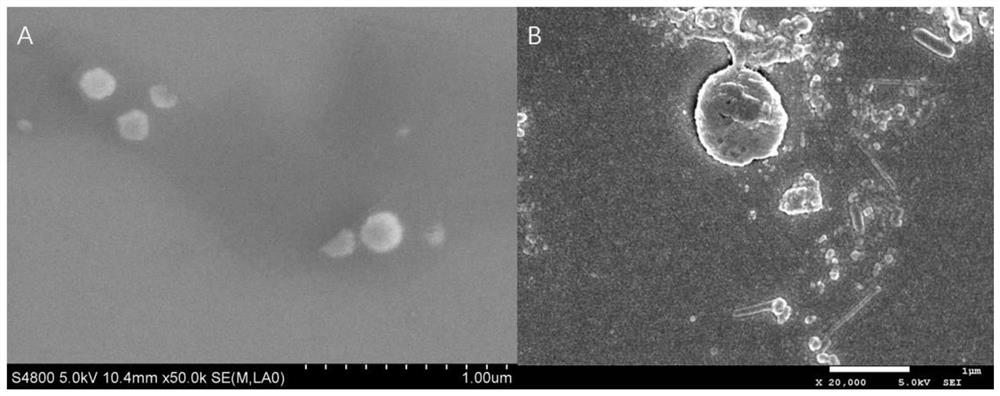

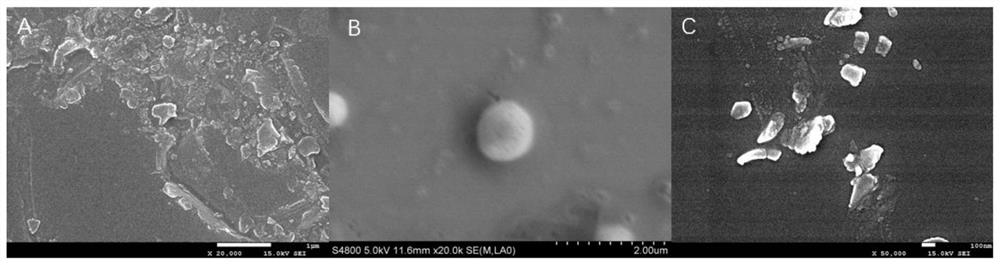

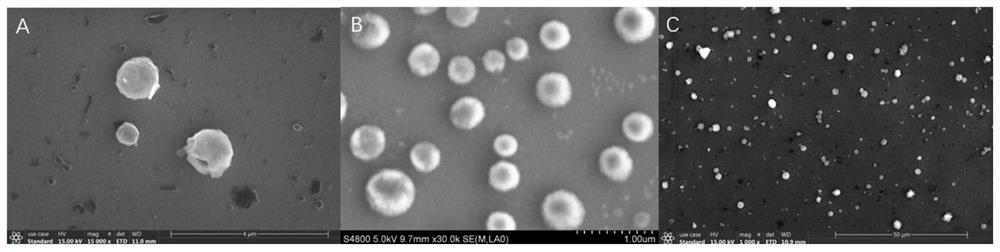

Image

Examples

Embodiment 1

[0051] Embodiment 1: a kind of preparation method of polydiacetylene vesicle with excellent performance, it comprises the following steps:

[0052] S1. Dissolution: Dissolve the 10,12-pentacosadiynoic acid monomer in ethanol, the molar concentration of the monomer is 0.5mM, the dissolution time is 5min, and microfilter with PVDF containing 0.45μm after dissolution Filter through the filter head of the membrane to obtain the filtrate;

[0053] S2. Film formation: Pour the filtrate from step S1 into a spherical bottle, and form a monomer molecular film by rotary evaporation. The rotational speed of the rotary evaporator is 30r / min, the pressure is -0.065Mpa, and the temperature of the water bath is 68°C ;

[0054] S3. Add up water: slowly and uniformly add up water at 60°C to the formed monomer molecular film;

[0055] S4. Dispersion: Ultrasonic dispersion is used to disperse the monomer molecular film after adding up water to obtain an emulsion; the temperature of the ultraso...

Embodiment 2

[0058] Embodiment 2: a kind of preparation method of polydiacetylene vesicle with excellent performance, it comprises the following steps:

[0059] S1. Dissolution: Dissolve 10,12-trisosadiynoic acid monomer in ethanol, the molar concentration of the monomer is 2mM, the dissolution time is 5min, after dissolution, use a PVDF microfiltration membrane containing 0.45μm Filter through the filter head to obtain the filtrate;

[0060] S2. Film formation: Pour the filtrate from step S1 into a spherical bottle, and form a monomer molecular film by rotary evaporation. The rotational speed of the rotary evaporator is 40r / min, the pressure is -0.07Mpa, and the temperature of the water bath is 60°C. ;

[0061] S3. Add up water: slowly and uniformly add up water at 45°C to the formed monomer molecular film;

[0062] S4. Dispersion: Use ultrasonic dispersion to disperse the monomer molecular film after adding up water to obtain an emulsion; the temperature of the ultrasonic dispersion is...

Embodiment 3

[0065] Embodiment 3: a kind of preparation method of polydiacetylene vesicle with excellent performance, it comprises the following steps:

[0066] S1. Dissolution: Dissolve 10,12-pentacosadiyn-1-ol monomer in ethanol, the molar concentration of the monomer is 1mM, and the dissolution time is 5min. After dissolution, use PVDF containing 0.45μm Filter through the filter head of the microfiltration membrane to obtain the filtrate;

[0067] S2. Film formation: Pour the filtrate from step S1 into a spherical bottle, and form a monomer molecular film by rotary evaporation. The rotational speed of the rotary evaporator is 35r / min, the pressure is -0.068Mpa, and the temperature of the water bath is 63°C. ;

[0068] S3. Add up water: slowly and uniformly add up water at 50°C to the formed monomer molecular film;

[0069] S4. Dispersion: Ultrasonic dispersion is used to disperse the monomer molecular film after adding up water to obtain an emulsion; the temperature of the ultrasonic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com