Preparation method of double-rare-earth-doped TiO2 nanotube ordered array

A technology of nanotube arrays and ordered arrays is applied in the field of preparation of one-dimensional nanomaterial titanium dioxide composite modification, which can solve the problems of high cost, difficult to obtain nanotube thin films, difficult separation of nanotube arrays, etc. The effect of uniform film formation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Put 5×5cm Al 2 o 3 The ceramic sheet was ultrasonically cleaned in acetone, alcohol and deionized water for 10 min in sequence;

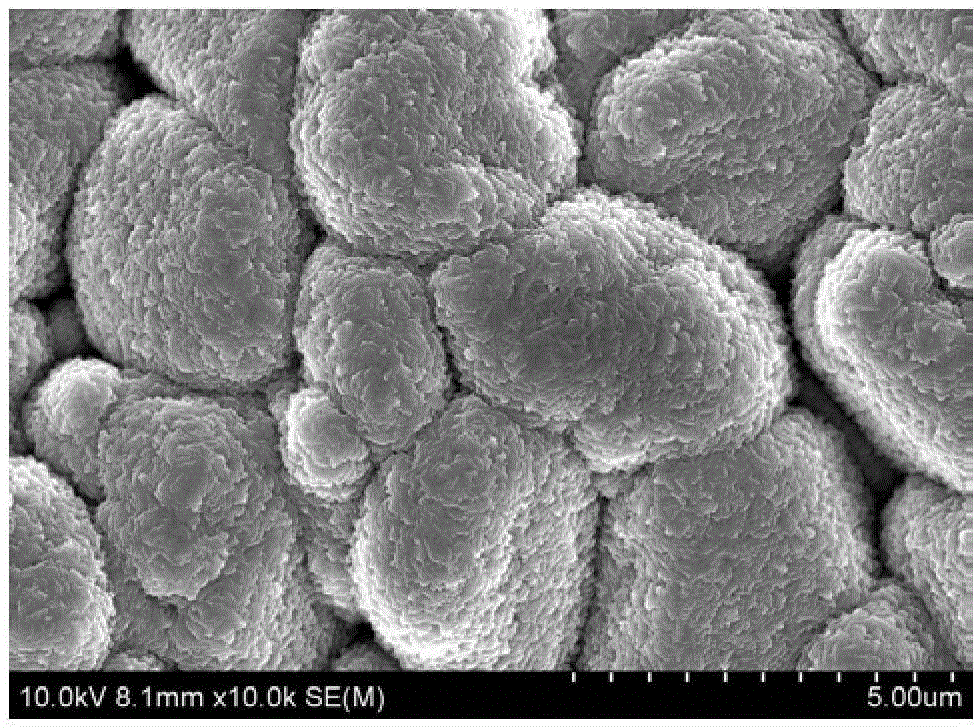

[0036] (2) Place the ceramic sheet in (1) in the magnetron sputtering chamber, use DC sputtering titanium target, sputter a layer of pure Ti, sputtering power 200W, sputtering time 1h, pure argon gas flow rate 20sccm, Back vacuum degree 4.0×10 -4 Pa, the sputtering pressure is 0.3pa, and the final titanium film thickness is about 1.5μm;

[0037] (3) To prepare an anodic oxidation solution, measure 360ml of glycerin, 40ml of deionized water, and weigh NH 4 F4.7972g.

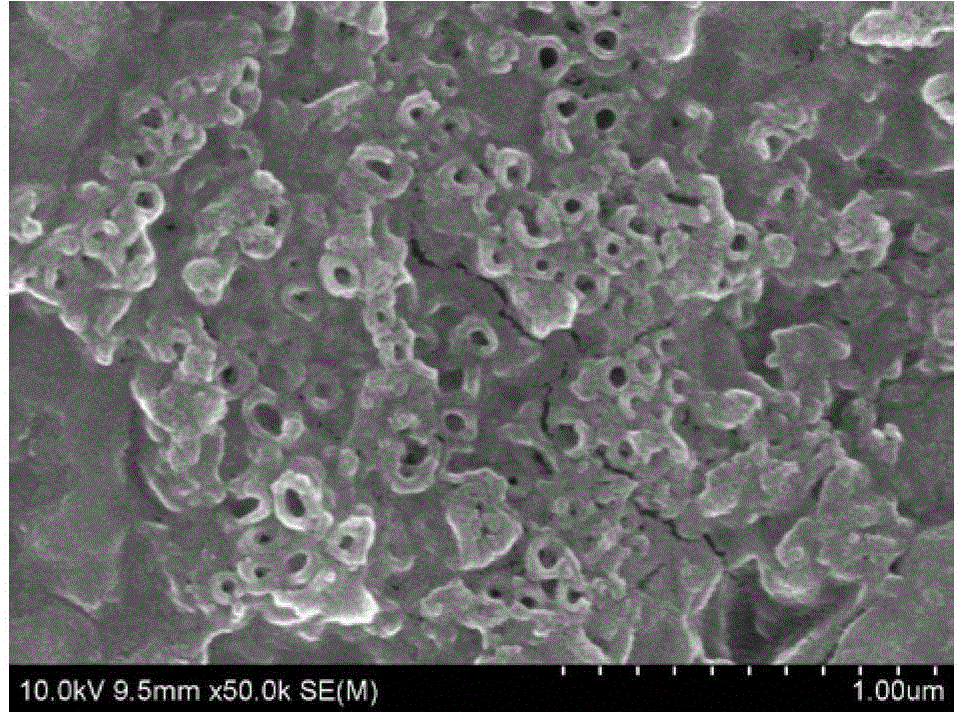

[0038] (4) Anodize the titanium film obtained in (2) with a voltage of 10V and a time of 2h.

[0039] (5) Prepare double rare earth doping solution, measure 100ml deionized, 0.0962g lanthanum nitrate, 0.0533g gadolinium nitrate;

[0040] (6) TiO obtained in (4) 2 The nanotube array is soaked in the solution prepared in step (5), placed in an oven, subjected to hydrotherm...

Embodiment 2

[0043] (1) Al 2 o 3 The ceramic sheet was ultrasonically cleaned in acetone, alcohol and deionized water for 10 min in sequence;

[0044] (2) Place the ceramic sheet in (1) in the magnetron sputtering chamber, use DC sputtering titanium target, sputter a layer of pure Ti, sputtering power 150W, sputtering time 2h, pure argon gas flow rate 60sccm, Back vacuum degree 9.0×10 -4 Pa, the sputtering pressure is 0.6pa, and the final titanium film thickness is about 1.3μm; the substrate temperature is 200°C;

[0045] (3) Configure the electrolyte for anodic oxidation, measure 360ml of glycerin, 36ml of deionized water, and weigh NH 4 F4.7972g.

[0046] (4) Perform anodic oxidation on the titanium film obtained in (2) with a voltage of 30V and a time of 0.5h.

[0047] (5) Prepare double rare earth doping solution, measure 100ml deionized, 0.1920g lanthanum nitrate, 0.1327g gadolinium nitrate;

[0048] (6) TiO obtained in (4) 2 The nanotube array was soaked in the solution prepar...

Embodiment 3

[0051] (1) Al 2 o 3 The ceramic sheet was ultrasonically cleaned in acetone, alcohol and deionized water for 10 min in sequence;

[0052] (2) Place the ceramic sheet in (1) in the magnetron sputtering chamber, use DC sputtering titanium target, sputter a layer of pure Ti, sputtering power 180W, sputtering time 2h, pure argon gas flow rate 80sccm, Back vacuum degree 6.0×10 -4 Pa, the sputtering pressure is 0.8pa, and the final titanium film thickness is about 1.3μm; the substrate temperature is 400°C;

[0053] (3) Prepare the electrolyte for anodic oxidation, measure 360ml of glycerin, 40ml of deionized water, and weigh 4.8044g of NH4F.

[0054] (4) Anodize the titanium film obtained in (2) with a voltage of 20V and a time of 1h.

[0055] (5) Prepare double rare earth doping solution, measure 100ml deionized, 0.1432g lanthanum nitrate, 0.0668g gadolinium nitrate;

[0056] (6) TiO obtained in (4) 2 The nanotube array was soaked in the solution prepared in step (5), put int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com