Special plate lug insulation adhesive tape for nickel-metal hydride battery, as well as production method of special plate lug insulation adhesive tape

A technology for nickel-metal hydride batteries and insulating adhesives, used in adhesives, battery pack parts, natural rubber adhesives, etc., can solve the problems of low temperature resistance, unenvironmental raw materials, and reduced peeling force, and improve strong alkali resistance. , excellent adhesion, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

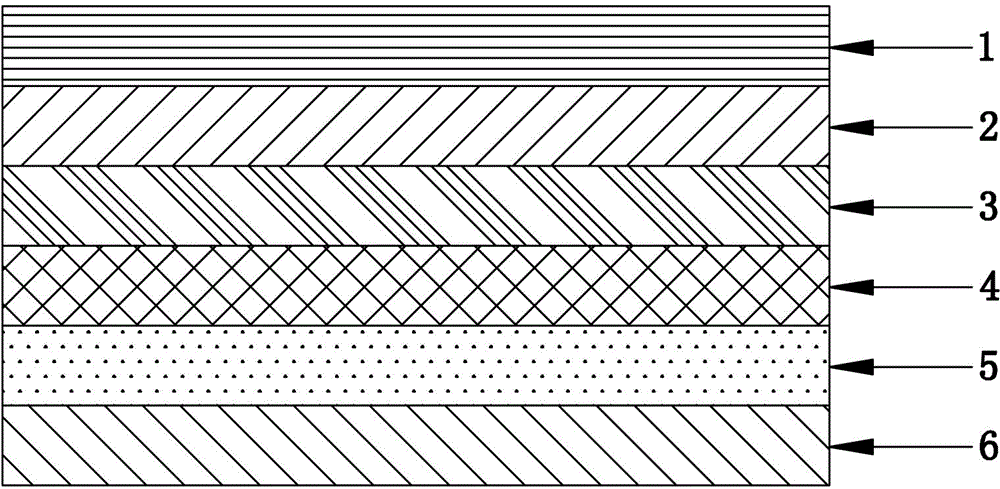

[0038] Such as figure 1 As shown, a tab insulation adhesive tape for nickel-metal hydride batteries includes a rubber adhesive layer 1, a protective layer 2, an ink layer 3, a primer layer 4, a base layer 5 and a release layer 6 distributed in sequence, and the base layer 3 is a biaxially oriented polypropylene film, the primer layer 2 is arranged on the front of the base layer 3, the ink layer 3 is arranged on the outer surface of the primer layer 4, and the protective layer 2 is arranged on the outer surface of the ink layer 3, so The release layer 6 is a single-component non-silicon release agent coating, the release layer 6 is arranged on the back of the base layer 5, and the rubber adhesive layer 1 is arranged on the outer surface of the protective layer 2 .

[0039] The thickness of the base layer 5 is 0.036mm to 0.065mm. The base layer 5 is a b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com