Heat-resistant insulating paint with fast curing speed

A technology with fast curing speed and heat-resistant insulation. It can be used in epoxy resin coatings and coatings to solve the problems of low use efficiency and slow curing speed, and achieve the effect of reducing emissions, improving curing speed and high reactivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

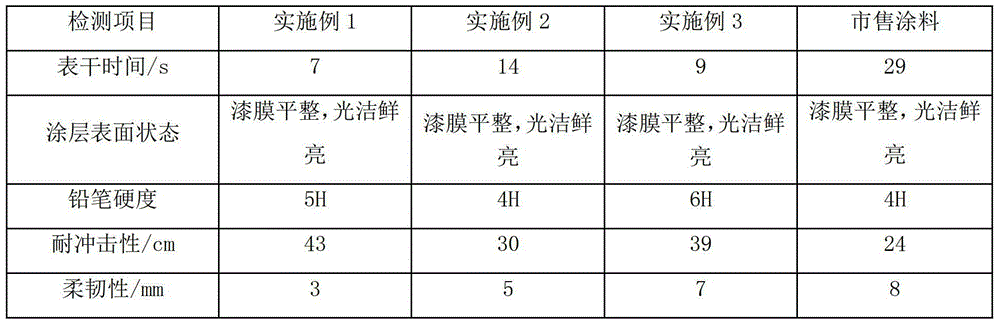

Examples

Embodiment 1

[0030] (1) First weigh each component according to the corresponding mass percentage in formula table 1, and set aside;

[0031] (2) Add talcum powder, mica powder, defoamer, leveling agent, wetting dispersant and pigment into the active diluent as fillers, disperse with a high-speed dispersing homogenizer for 10 minutes, and ultrasonicate for 5 minutes to disperse and Ultrasound is one cycle, and the treatment is repeated for 5 cycles to obtain a dispersion;

[0032] (3) Mix the dispersion liquid prepared in step (2) with epoxy acrylate and photoinitiator, and after stirring evenly, adopt the method of high-speed dispersion and ultrasonic treatment in step (2) alternately for 5 cycles, paint is obtained.

Embodiment 2-3

[0034] (1) Weigh the corresponding components according to the formula table 1 for later use;

[0035] All the other steps are the same as in Example 1.

[0036] Table 1 Formulation table Unit (%)

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com