Ultraviolet curing printing ink as well as preparation method and security product thereof

An ink and ultraviolet technology, applied in the field of printing, can solve the problems of low color saturation, unable to meet the needs of micro-pattern printing effect, and inaccurate filling of micro-patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

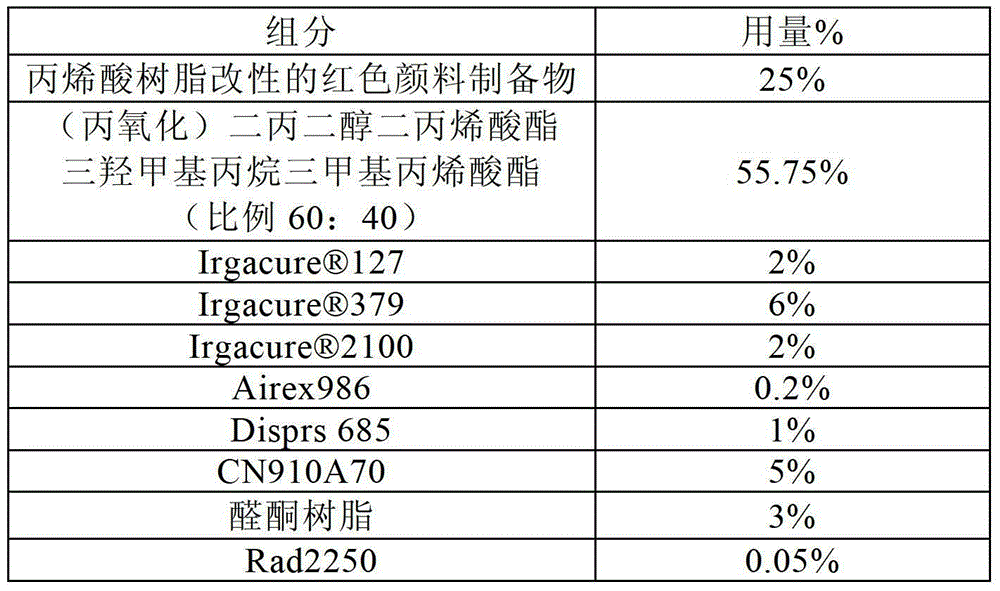

[0040] According to the formula of table 1, the red pigment preparation (produced by BASF, trade name: Composite reactive monomer (60:40 ratio) composed of (propoxylated) dipropylene glycol diacrylate and trimethylolpropane trimethacrylate (ratio: 60:40) and wetting and dispersing agent (manufactured by Tego, trade name: Disprs685) After mixing and stirring at a speed of 800-1200 rpm for 30 minutes, then grind to make a color paste with a particle size of <400nm, wherein the viscosity of the composite active monomer at 25°C is ≤70mPa·s;

[0041] The defoamer (produced by Tego, trade name: Airex986), prepolymer (produced by Sartomer, trade name: CN910A70), aldehyde and ketone resin and radiation curing additive (produced by Tego, trade name: Rad2250 ) According to the formula in Table 1, add it to the above color paste, and stir it thoroughly to make premixed ink;

[0042] will be given by Add the composite photoinitiator to the premixed ink prepared above, and stir for 30 ...

Embodiment 2

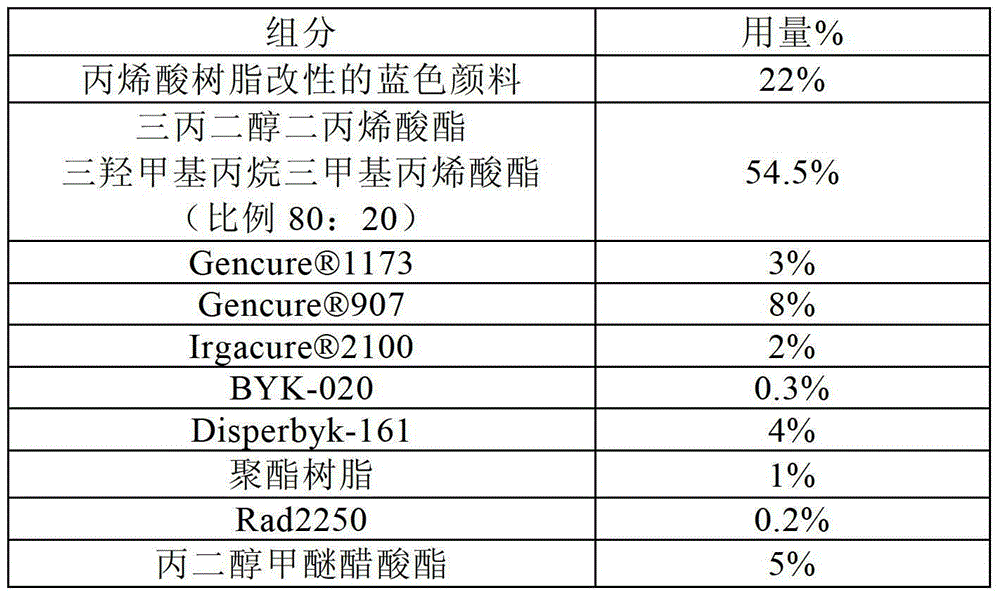

[0050] According to the formula of table 2, the blue pigment (produced by BASF company, trade name: A composite reactive monomer (80:20 ratio) composed of tripropylene glycol diacrylate and trimethylolpropane trimethacrylate and a wetting and dispersing agent (manufactured by BYK, trade name: Disperbyk-161) were prepared at 800 - Mixing and stirring at a speed of 1200 rpm for 30 minutes, and then grinding to make a color paste with a particle size of <400nm, wherein the viscosity of the composite active monomer at 25°C is ≤70mPa·s;

[0051] Add defoamer (manufactured by BYK, trade name: BYK-020), polyester resin, radiation curing additive (produced by Tego, trade name: Rad2250) to the above color paste according to the formula in Table 2, and fully Stir to make premixed ink;

[0052] will be given by Add the composite photoinitiator and propylene glycol methyl ether acetate to the premixed ink prepared above, and stir for 30 minutes to make a finished UV-curable ink with a...

Embodiment 3

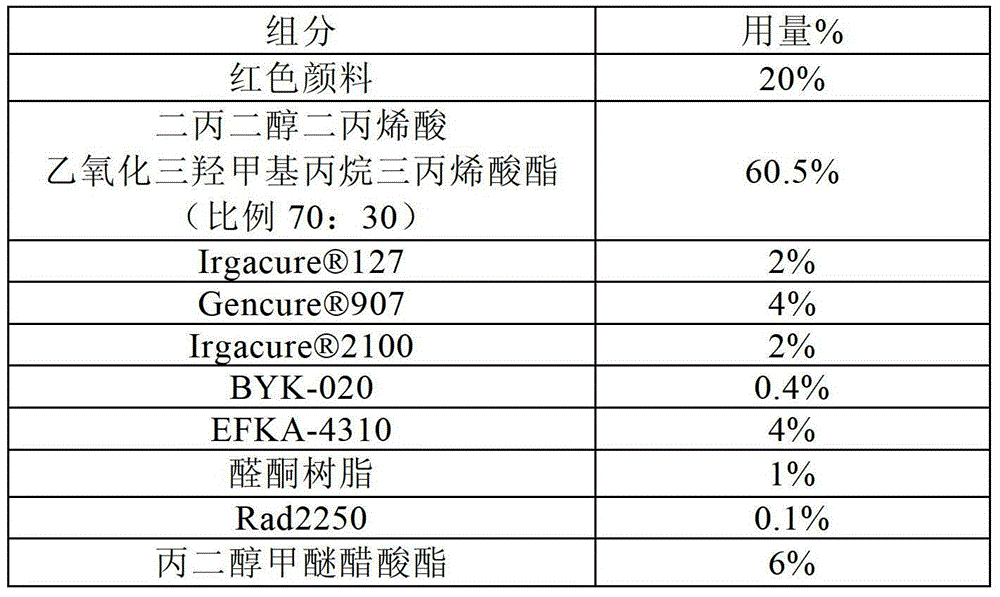

[0056] According to the formula in Table 3, the red pigment (produced by Clariant, trade name: 206153), the composite active monomer composed of dipropylene glycol diacrylate and ethoxylated trimethylolpropane triacrylate (the ratio is 70: 30) and wetting and dispersing agent (manufactured by EFKA, trade name: EFKA-4310) at a speed of 800-1200 rpm, mixed and stirred for 30 minutes, and then ground to make a color paste with a particle size of <400nm, wherein , the viscosity of the composite active monomer at 25°C is ≤70mPa·s;

[0057] Add defoamer (produced by BYK company, trade name: BYK-020), aldehyde and ketone resin, radiation curing additive (produced by Tego, trade name: Rad2250) to the above-mentioned color paste according to the formula in Table 3, and fully Stir to make premixed ink;

[0058] will be given by Add the composite photoinitiator and propylene glycol methyl ether acetate to the premixed ink prepared above, and stir for 30 minutes to make a finished UV-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com