Enhanced sewage biological nitrogen and phosphorus removal method bases on polyhydroxyalkanoate metabolism regulation

A polyhydroxyalkanoate, metabolic regulation technology, applied in biological sludge treatment, chemical instruments and methods, biological water/sewage treatment, etc. To deal with other problems, to achieve the effect of improving efficiency, easy to promote large-scale, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

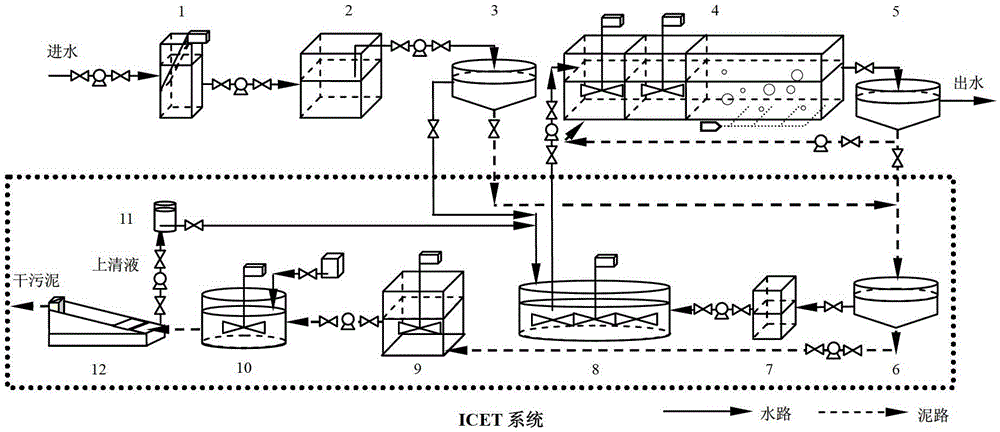

[0036] (1) if figure 1 As shown, the organic waste obtained by the sewage through the grid 1, the regulating tank 2 and the primary sedimentation tank 3 and the remaining sludge of the secondary sedimentation tank 5 are introduced into the sludge thickening tank 6 for concentration and sedimentation for 24 hours at a VSS ratio of 1:1;

[0037] (2) The concentrated mixture enters the PHA precursor production reactor 9 (anaerobic fermentation for 8 days under the condition of controlling pH=10.0) and is directional converted into PHA precursor;

[0038] (3) The obtained PHA precursor (concentration is 4650mg COD / L, the contents of acetic acid and propionic acid are 48% and 41% respectively) enters the sludge dehydrator 12 after removing nitrogen and phosphorus in the sludge conditioning tank 10, and the obtained liquid pumps Enter the PHA precursor storage pool 11 for storage;

[0039] (4) Pump the liquid in the supernatant storage tank 7 and the PHA precursor into the PHA prod...

Embodiment 2

[0042] (1) if figure 1 As shown, the organic waste obtained by the sewage through the grid 1, the regulating tank 2 and the primary sedimentation tank 3 and the remaining sludge of the secondary sedimentation tank 5 are introduced into the sludge concentration tank 6 for concentration and precipitation for 12 hours at a VSS ratio of 10:1;

[0043] (2) The concentrated mixture enters the PHA precursor production reactor 9 (anaerobic fermentation under the condition of controlling pH=8.0 for 8 days);

[0044](3) The obtained PHA precursor (concentration is 4230mg COD / L, the contents of acetic acid and propionic acid are 56% and 28% respectively) enters the sludge dehydrator 12 after removing nitrogen and phosphorus in the sludge conditioning tank 10, and the obtained liquid pumps Enter the PHA precursor storage pool 11 for storage;

[0045] (4) Pump the liquid in the supernatant storage tank 7 and the PHA precursor into the PHA production reactor 8 (control pH=6.8, react for 3....

Embodiment 3

[0047] (1) if figure 1 As shown, the organic waste obtained by the sewage through the grid 1, the regulating tank 2 and the primary sedimentation tank 3 and the remaining sludge of the secondary sedimentation tank 5 are introduced into the sludge concentration tank 6 for concentration and precipitation for 24 hours at a VSS ratio of 5:1;

[0048] (2) The concentrated mixture enters the PHA precursor production reactor 9 (anaerobic fermentation under the condition of controlling pH=8 for 8 days);

[0049] (3) The obtained PHA precursor (concentration is 4310mg COD / L, the contents of acetic acid and propionic acid are 50% and 31% respectively) enters the sludge dehydrator 12 after removing nitrogen and phosphorus in the sludge conditioning tank 10, and the obtained liquid pumps Enter the PHA precursor storage pool 11 for storage;

[0050] (4) Pump the liquid in the supernatant storage tank 7 and the PHA precursor into the PHA production reactor 8 (control pH=7.2, react for 3.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com