Technology treatment method of machining deformation of long and thin hole shaft type thin-wall part

A technology for thin-walled parts and processing deformation, which is applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as piston rod processing deformation, reduce processing deformation, improve dimensional stability, and reduce the amount of retained austenite Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

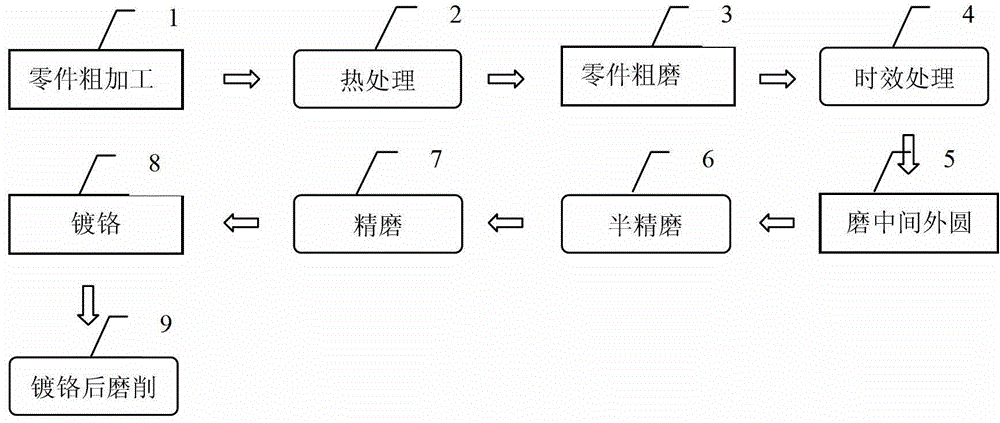

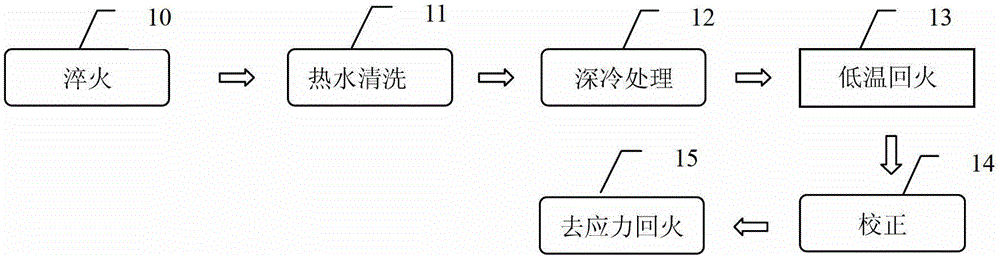

[0023] see figure 1 , figure 2 . The processing method for processing deformation of thin-walled blind hole parts with elongated holes and shafts proposed by the present invention includes rough machining of parts 1, heat treatment 2, rough grinding of parts 3, aging treatment 4, middle outer circle grinding 5, semi-finish grinding 6, Fine grinding 7, chrome plating, grinding after chrome plating. Heat treatment 2 includes quenching 10, hot water washing 11, cryogenic treatment 12, low temperature tempering 13, correction 14, and stress relief tempering 15, wherein:

[0024] Rough machining of parts 1: A machining allowance of 0.50-0.55mm is left on the carburized surface of the outer circle, and the accuracy requirement of the runout of the outer circle is guaranteed to be ≤0.10 after rough machining. In part heat treatment 2: the process flow of quenching, hot water cleaning, cryogenic treatment, low temperature tempering, correction, stress relief tempering and inspecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com