Broken metal filing filtering and collecting device

A collection device and technology for metal shavings, applied in the direction of metal processing equipment, metal processing machinery parts, maintenance and safety accessories, etc., can solve problems such as difficult separation and cleaning, affecting processing quality and work efficiency, and increasing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

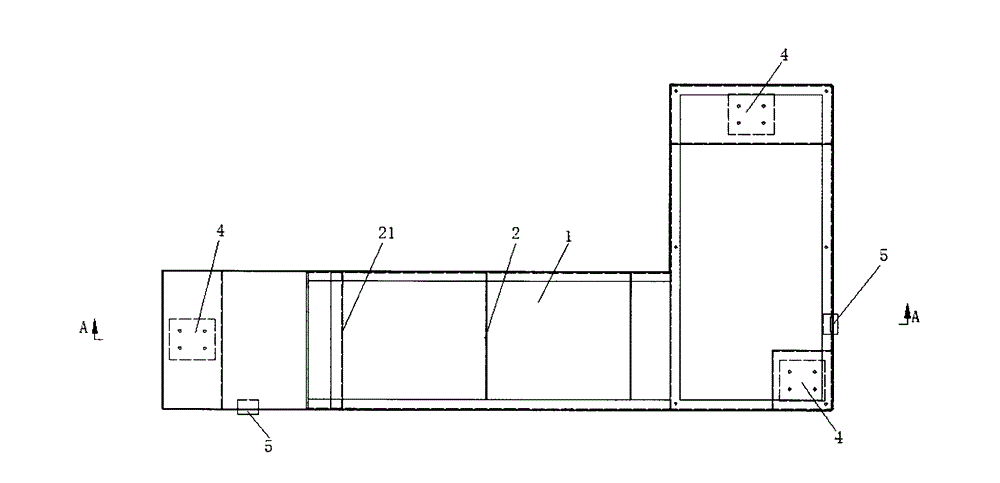

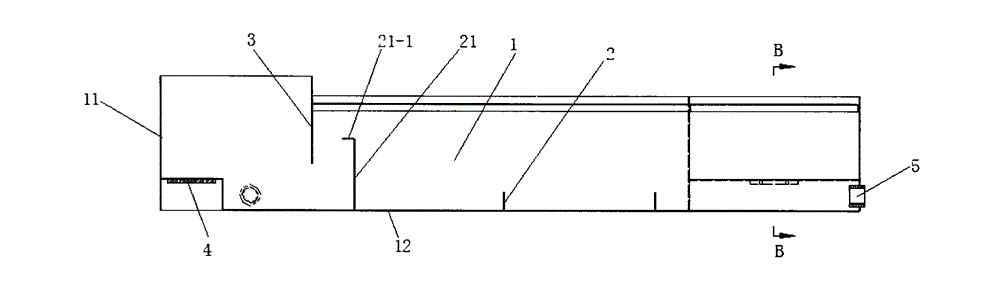

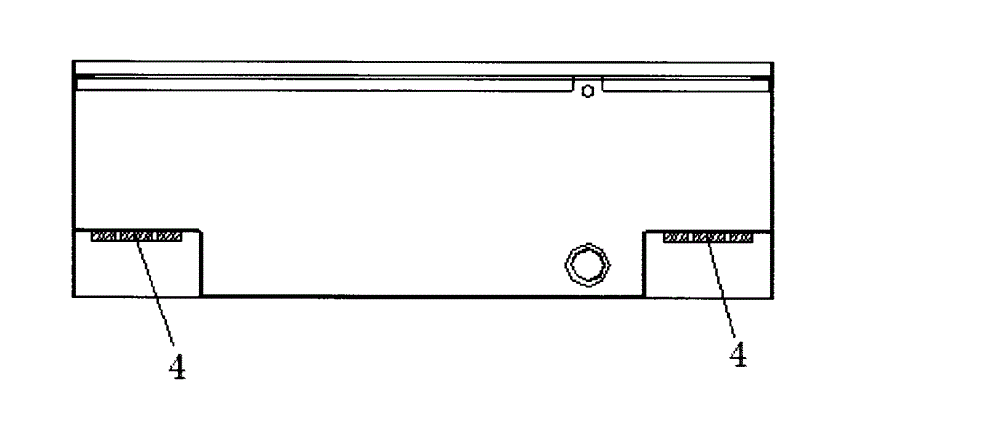

[0027] See Figure 1 to Figure 3 , a kind of filtering and collecting device for processing broken metal shavings of the embodiment, including a water tank 1 with an open upper part for containing coolant; a water baffle 2 is arranged longitudinally in the water tank 1, and the height of the water baffle 2 is lower than that of the water tank The height of the side wall 11 of 1; the water baffles 2 can be arranged in parallel with each other and at intervals, and among the multiple water baffles 2, the height of the first water baffle 21 close to the cooling liquid collection port is higher than that of other water baffles 2; The top of the first water baffle 21 is provided with a bent portion 21-1 inclined toward the coolant collection port; a suspended deflector 3 is provided in the water tank 1; the suspended deflector 3 is located in front of the first water deflector 21 , the height of its low end is lower than the height of the top of the first water baffle 21; a strong ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com