Guide vane body oil hole machining method

A processing method and technology for a guide vane body are applied in the field of oil hole processing of the guide vane body, which can solve the problems of high production cost, economic loss, and high technical level of processing personnel, and achieve the effect of simple method and production cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] This method is further described in conjunction with accompanying drawing:

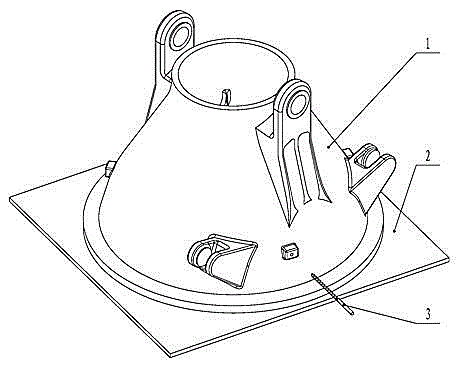

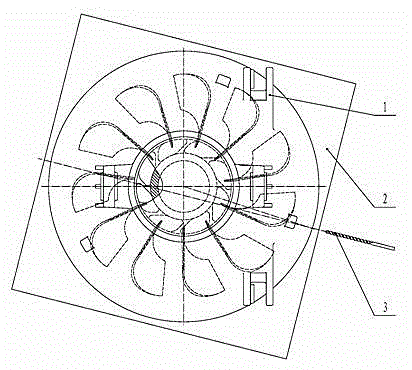

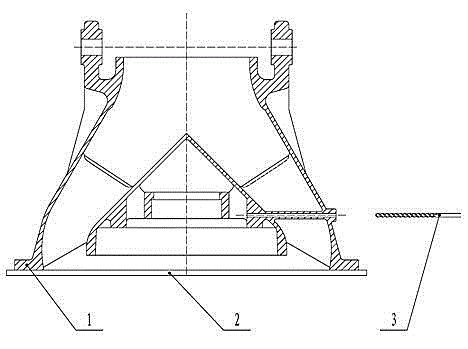

[0011] figure 1 Shown are guide vane body 1, plate 2 and drill bit 3, figure 2 The line passing through the boss and the outer circle of the flange of guide vane body 1 is the center line of the oil hole. The corresponding part of the boss is a thick airfoil blade. The center line of guide vane body 1 and the center line of oil hole There are two intersection points on the outer circle of the flange of the body 1, and the chord length between the two intersection points is measured in the design drawing; the outer circle of the blank flange of the guide vane body 1 is processed to the design size according to the requirements of the design drawing. Align the horizontal centerline of guide vane body 1 and mark (two) horizontal lines on the outer circle of guide vane body 1 flange, and make oil holes on the outer circle of guide vane body 1 flange according to the measured chord length Centerl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com