Air exhausting device of free-flow electrophoresis separation cavity and implementation method of air exhausting device

A separation device, electrophoresis separation technology, applied in the direction of separation method, material separation, measuring device, etc., can solve the problem of air discharge, etc., and achieve the effect of low equipment cost, reasonable design and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

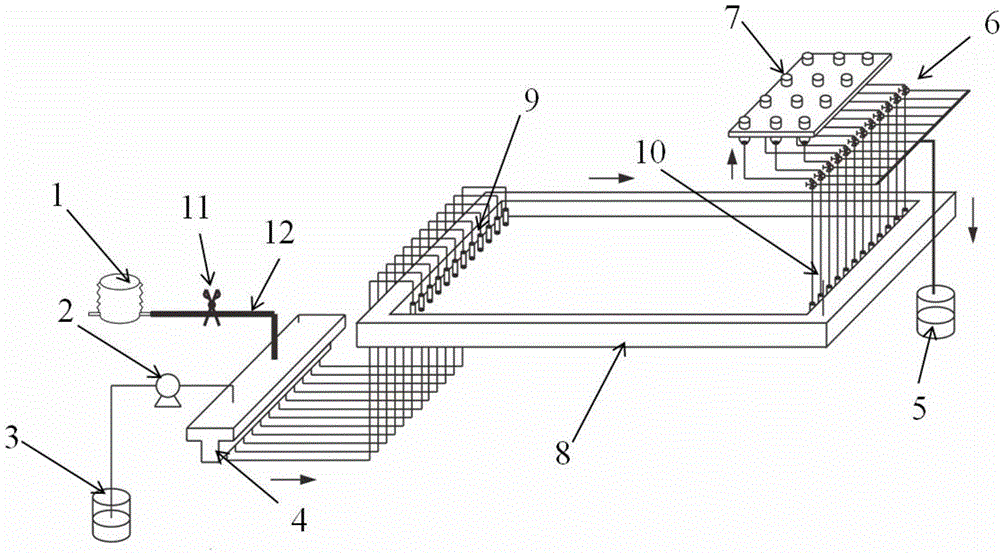

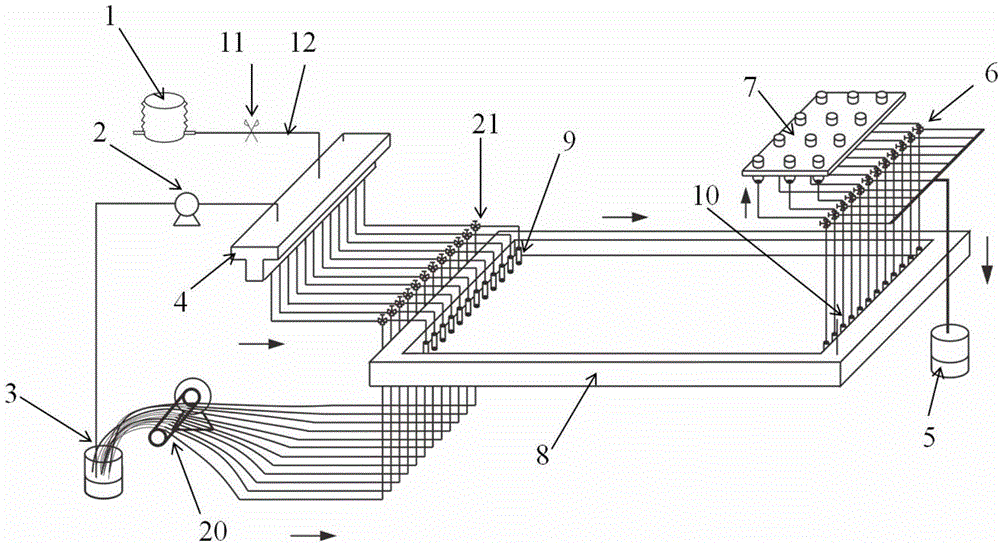

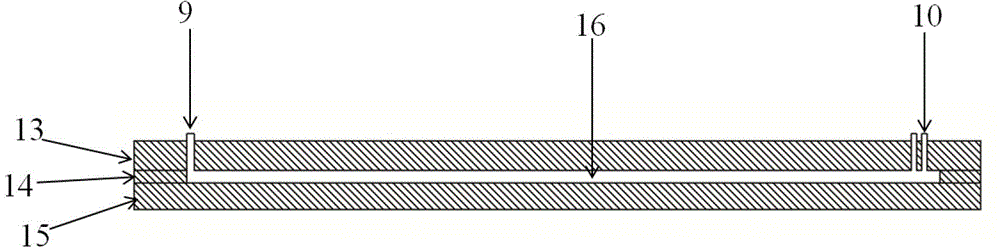

[0017] The first embodiment of the present invention is figure 1 , image 3 and Figure 4 As shown, the present invention includes a buffer liquid storage bottle 3, a buffer liquid pump 2, a manual air cylinder 1, a hose clamp 11, a rubber hose 12, a gas-liquid buffer separation device 4, a self-balancing recovery device 7, and a separation chamber housing 8 , a separation chamber 16, a waste liquid recovery bottle 5 and a recovery three-way valve 6, the inlet of the buffer pump 2 is connected with the buffer liquid storage bottle 3 through a connecting pipe, and the upper end surface of the gas-liquid buffer separation device 4 has a gas-liquid buffer The separation device air inlet 17 and the gas-liquid buffer separation device liquid inlet 18, the lower end surface of the gas-liquid buffer separation device 4 has a plurality of gas-liquid buffer separation device liquid outlets 19; the separation chamber shell 8 is composed of a separation chamber upper cover plate 13, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com