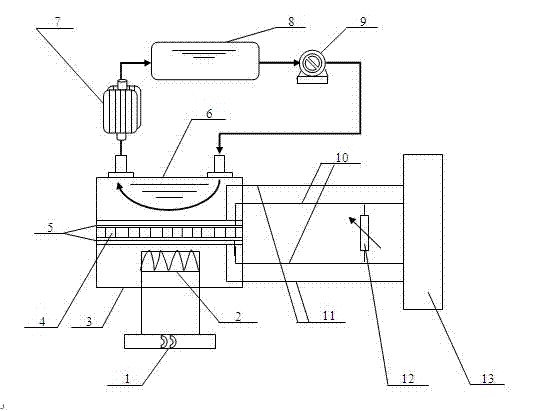

Thermoelectric material thermoelectric conversion performance testing system and method

A thermoelectric conversion and testing system technology, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problem that it is difficult to obtain the best working temperature and temperature difference of materials, cannot fully dissipate heat, and the temperature of the hot and cold ends of the thermoelectric power generation module cannot be solved. Measurement and other issues, to achieve good heat absorption and heat dissipation effect, reduce heat loss, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1. The thermoelectric conversion performance of the bismuth telluride material was tested under the condition of a load resistance of 3.9Ω. The results recorded by the multi-channel digital roving detector were as follows: during the temperature difference increased from 53.9K to 72.5K, the road The terminal voltage increases from 2.04V to 2.77V, the current increases from 0.14mA to 0.19mA, and the output power increases from 0.07mW to 0.14mW.

Embodiment 2

[0050] Example 2. The thermoelectric conversion performance of the bismuth telluride material was tested under the condition of a load resistance of 11.1Ω. The results recorded by the multi-channel digital roving detector were as follows: when the temperature difference increased from 53.9K to 72.5K, the road The terminal voltage increases from 2.09V to 3.03V, the current increases from 0.11mA to 0.14mA, and the output power increases from 0.14mW to 0.21mW.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com