Evaluation method of composition segregation of low-carbon high-manganese steel continuous casting small square billet

A component segregation and billet technology, which is applied to the analysis of materials, material analysis using wave/particle radiation, and measurement devices, can solve the problems of inability to accurately quantify the degree of component segregation of continuous casting slabs, and achieve stable results and simple operation , the effect of a large amount of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

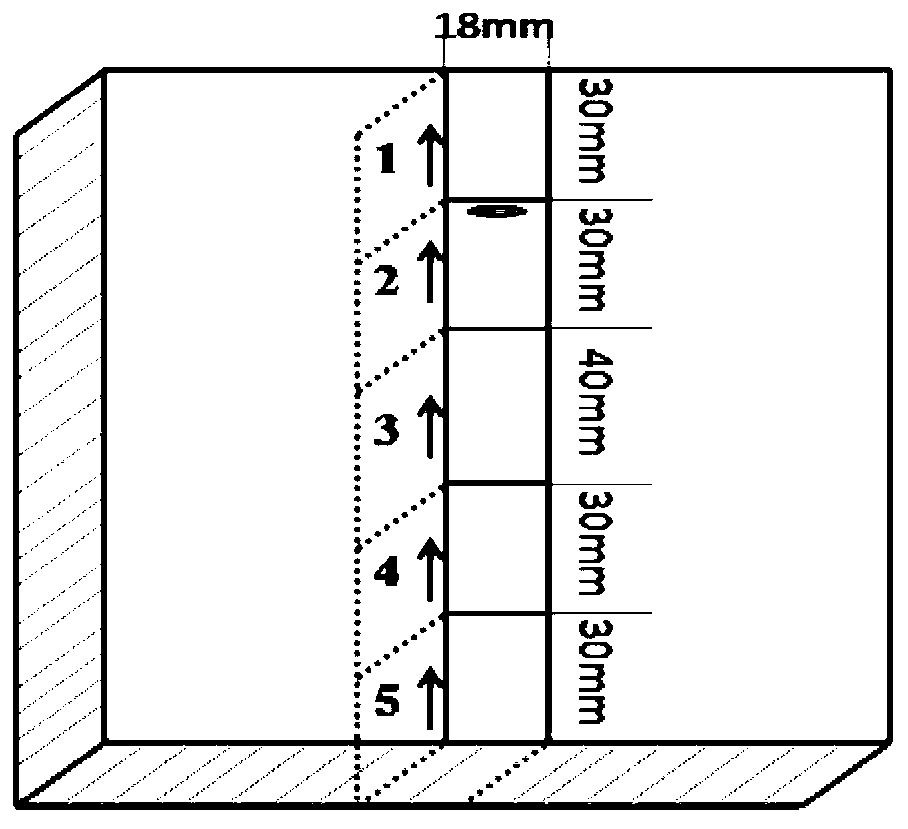

[0020] 160mm for low carbon and high manganese steel 2 The alloy welding wire continuous casting billet is analyzed, and the samples are divided into three groups: Group1, Group2 and Group3, of which Group2 is the sample of Group1 after simulating the billet heating furnace process on the rolling site, and the heating process is: 15℃ / min to 650°C; 10°C / min to 1100°C; post-holding for 36min, quenching and air cooling. The composition of the corresponding slab is shown in Table 1, and the continuous casting process is shown in Table 2. sampling methods such as figure 1 shown, at a position 35mm away from the edge of the slab (such as figure 1 ), select 3 to 4 fields of view for analysis.

[0021] Table 1 Chemical composition of samples

[0022] Numbering

C

Si

Mn

P

S

Ti

Alt

Als

Group1

0.077

0.87

1.46

0.014

0.014

0.004

0.008

0.007

Group3

0.077

0.86

1.46

0.01

0.013

0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com