Anti-gravity loop heat pipe and production method thereof

A technology of loop heat pipe and manufacturing method, applied in the direction of sustainable manufacturing/processing, indirect heat exchanger, lighting and heating equipment, etc., which can solve the problems of large temperature fluctuation, reduced heat transfer capacity, and limited heat transfer performance, etc. Achieve the effects of small temperature fluctuations, stable reflux speed, and improved heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

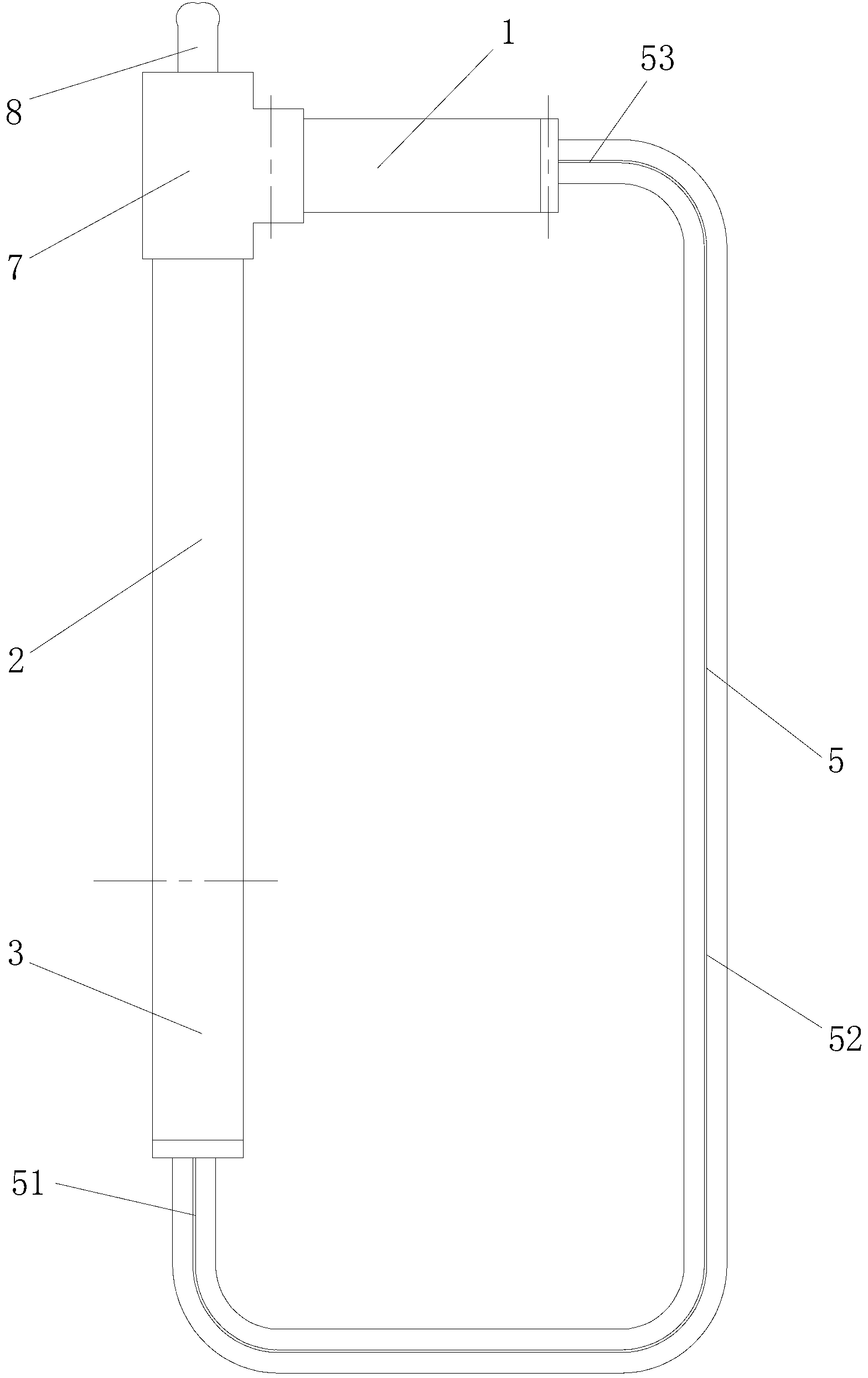

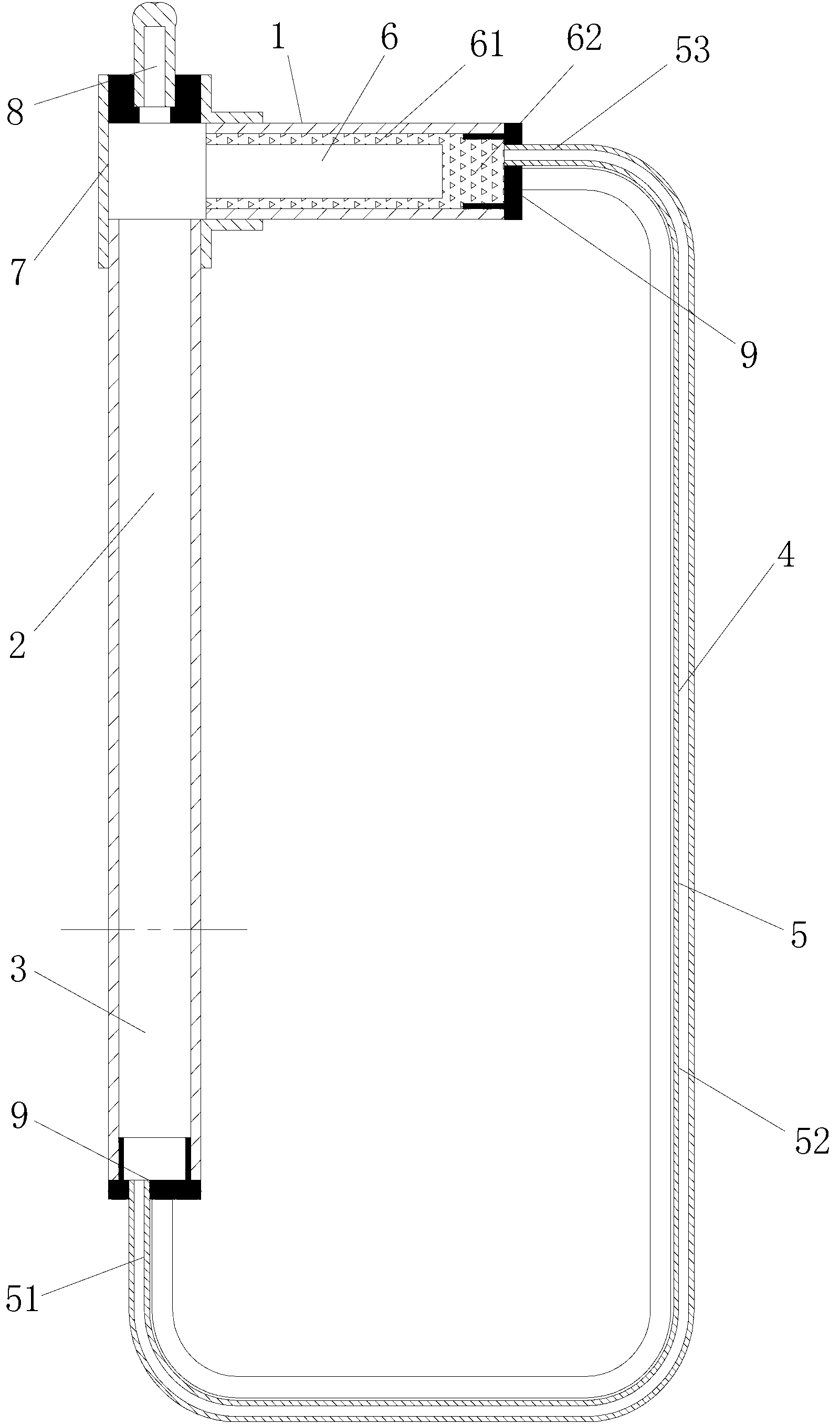

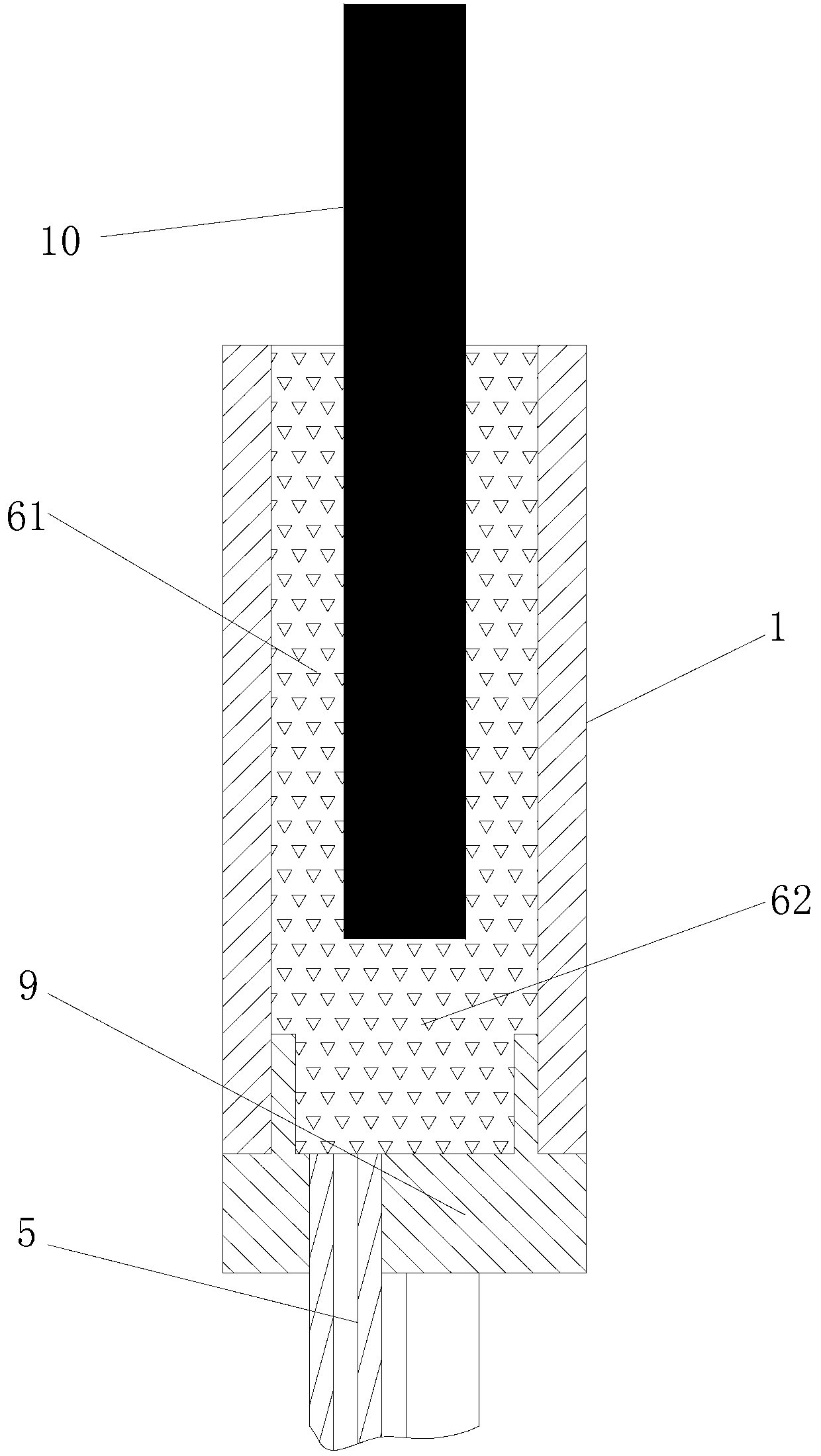

[0028] Such as figure 1 and figure 2 The anti-gravity loop heat pipe shown has an evaporation section 1, an adiabatic section 2, a condensation section 3, and an infusion section 4 that are sequentially connected end to end to form a loop. The infusion section 4 includes three capillary tubes 5, and the capillary tube 5 The two ends of the capillary are respectively connected with the evaporating section 1 and the condensing section 3; the inner diameters of the capillary 5 are smaller than the inner diameters of the tube bodies of the evaporating section 1 and the condensing section 3; The outlet end of the evaporation section 1 and the inlet end of the heat insulation section 2 are connected through the three-way adapter 7, that is, the outlet end of the evaporation section 1 and the inlet end of the heat insulation section 2 are respectively connected to the two interfaces of the three-way adapter 7 , and the third interface of the three-way adapter 7 is provided with a s...

Embodiment 2

[0043] The anti-gravity loop heat pipe is the same as the embodiment 1 except the following technical features: the number of the capillary 5 is two. The diameter of the inner hole of the capillary 5 is 0.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com