Light-emitting diode (LED) bulb lamp

A technology for LED bulbs and lamp caps, which is applied to the cooling/heating device, lighting device, light source and other directions of lighting devices, can solve problems such as unfavorable heat dissipation, insufficient understanding of heat dissipation mechanism, and reduced heat dissipation efficiency of light source modules, so as to improve the heat dissipation effect. , Improve heat dissipation efficiency and increase the effect of heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

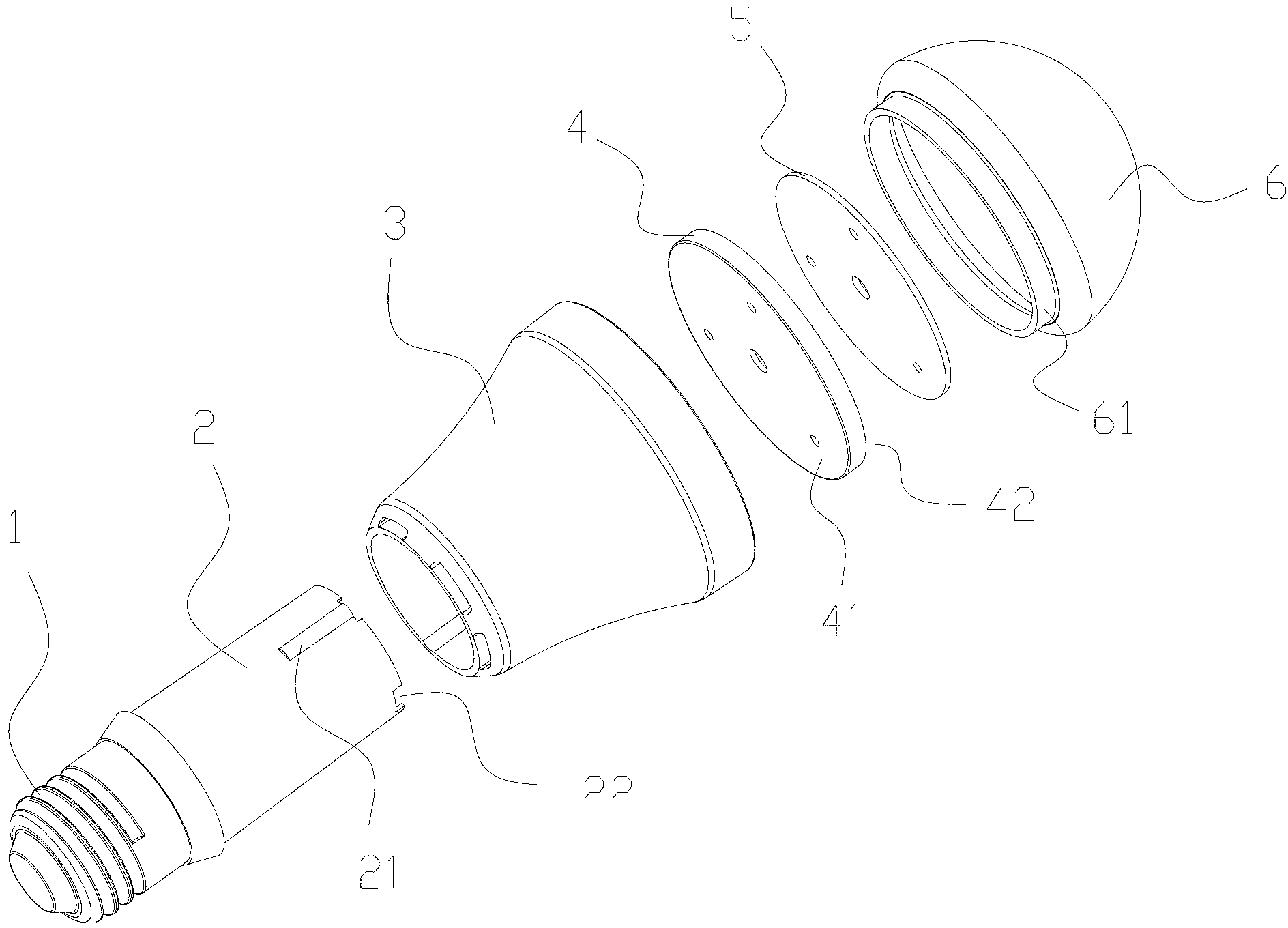

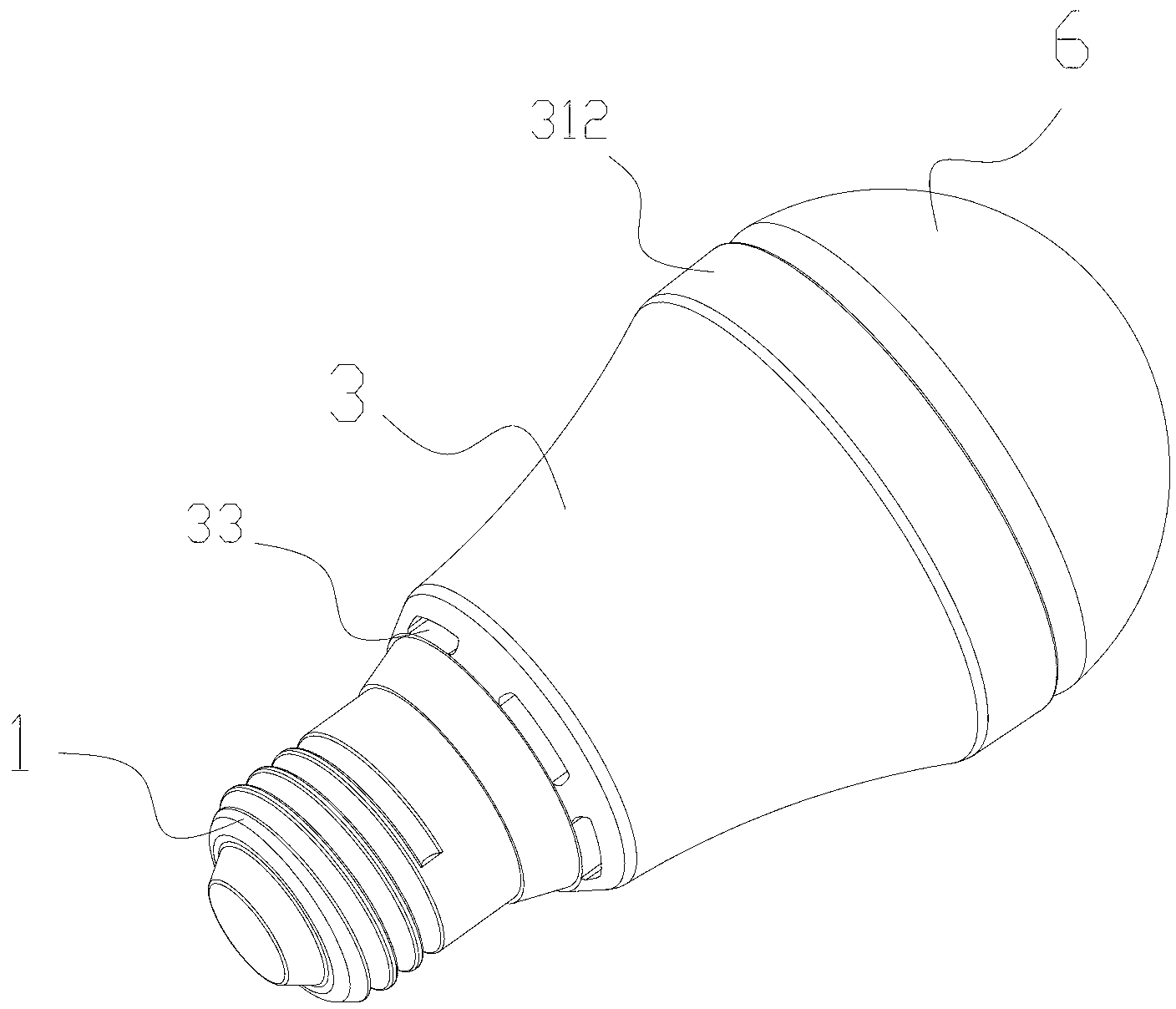

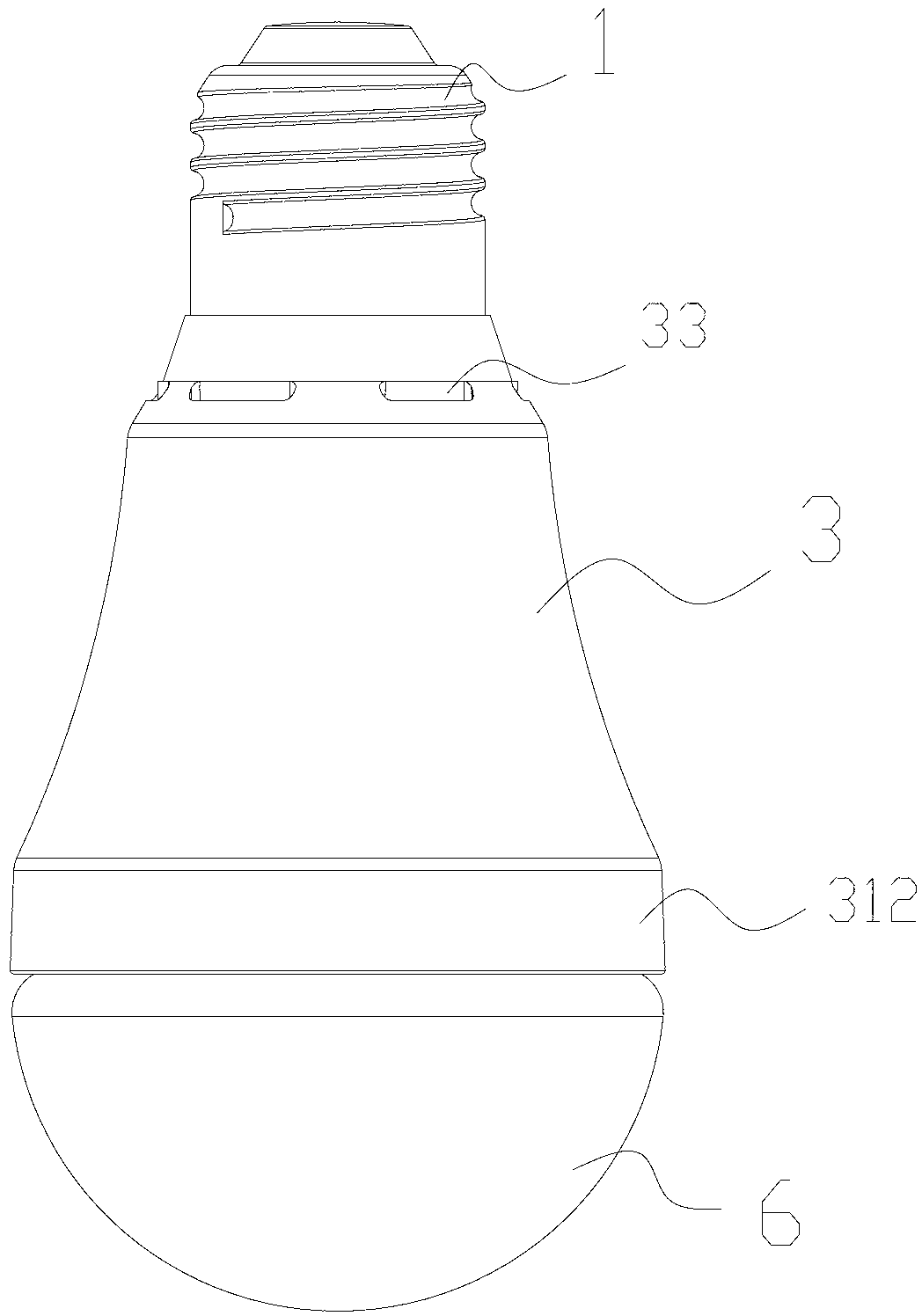

[0044] Such as Figure 1 to Figure 6 As shown, a schematic structural diagram of an LED bulb lamp in this embodiment, which includes a lamp base 1 , an inner container 2 , a power module, a heat dissipation lamp cup 3 , a heat dissipation substrate 4 , an LED light emitting board 5 and a lampshade 6 .

[0045] The lamp cap 1 is used to connect with the lamp socket connected to the mains, low-voltage electricity and other power sources. One end of it used to connect the lamp socket is a metal conductive and heat-conducting screw structure. The type of lamp head is the same, which is used to easily replace the traditional bulb lamp without additional replacement lamp holder. The other end of the lamp holder 1 is connected with the inner container 2 .

[0046] The liner 2 is made of insulating, heat-insulating, and heat-resistant materials, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com