Meta-position aramid fiber paper with high physical strength insulativity as well as preparation method and application thereof

A technology of physical strength and insulation, applied in pulp beating method, paper, papermaking, etc., can solve the problem of improper fiber pretreatment method and blending ratio, paper surface smoothness, mechanical strength, and paper dielectric strength that cannot meet the requirements of the product And other problems, to achieve the effect of low equipment requirements, good tensile strength, good electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

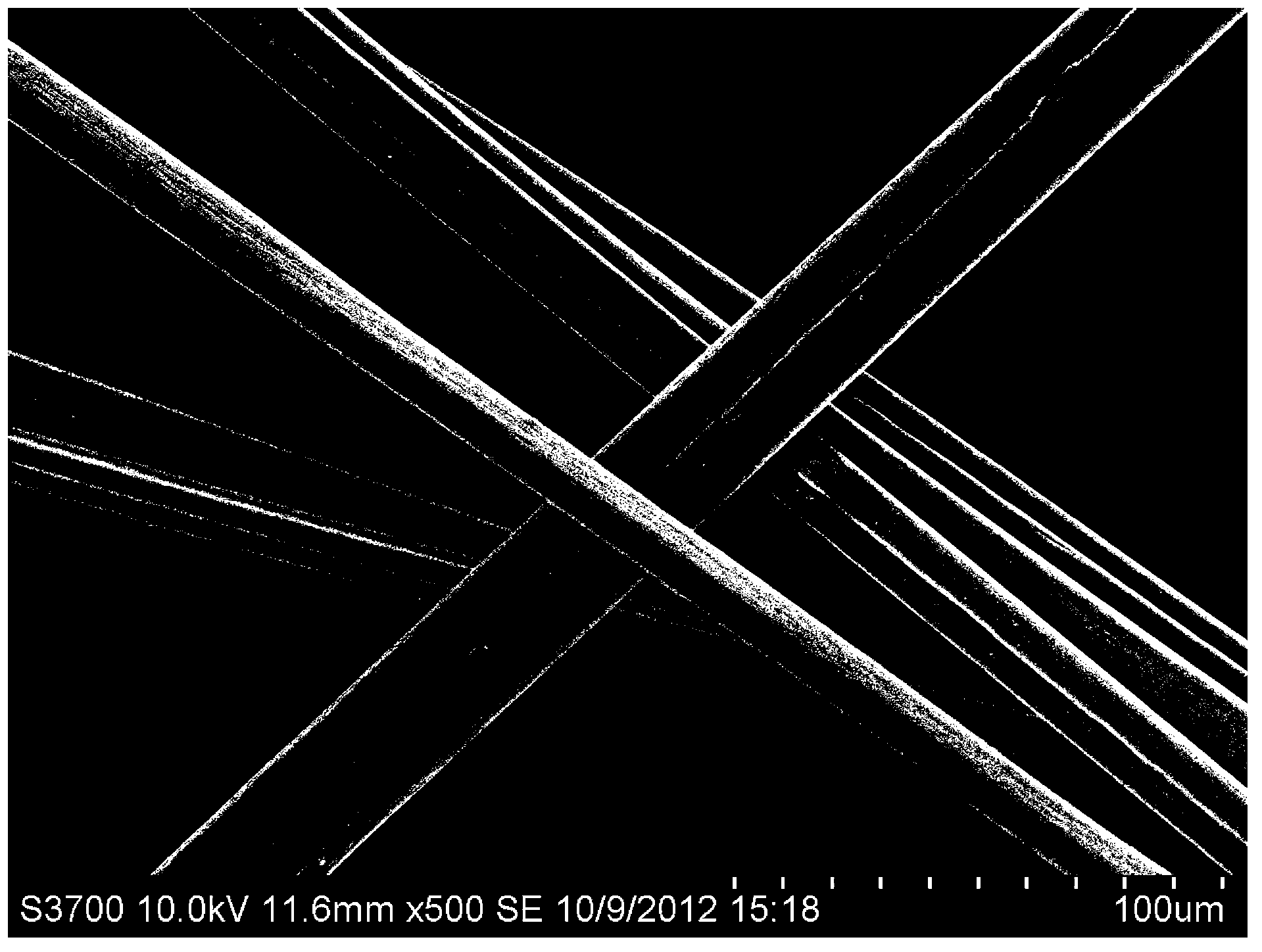

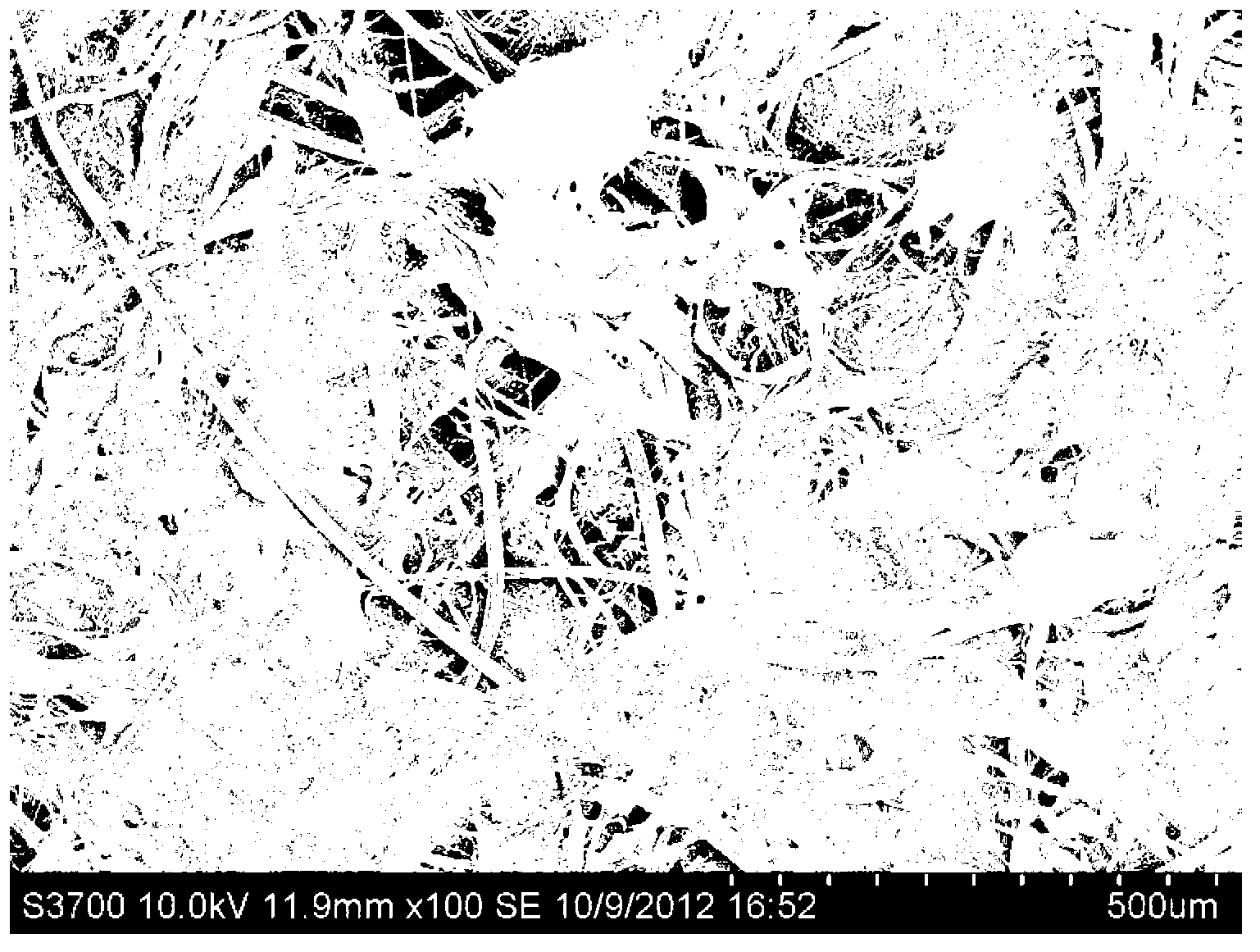

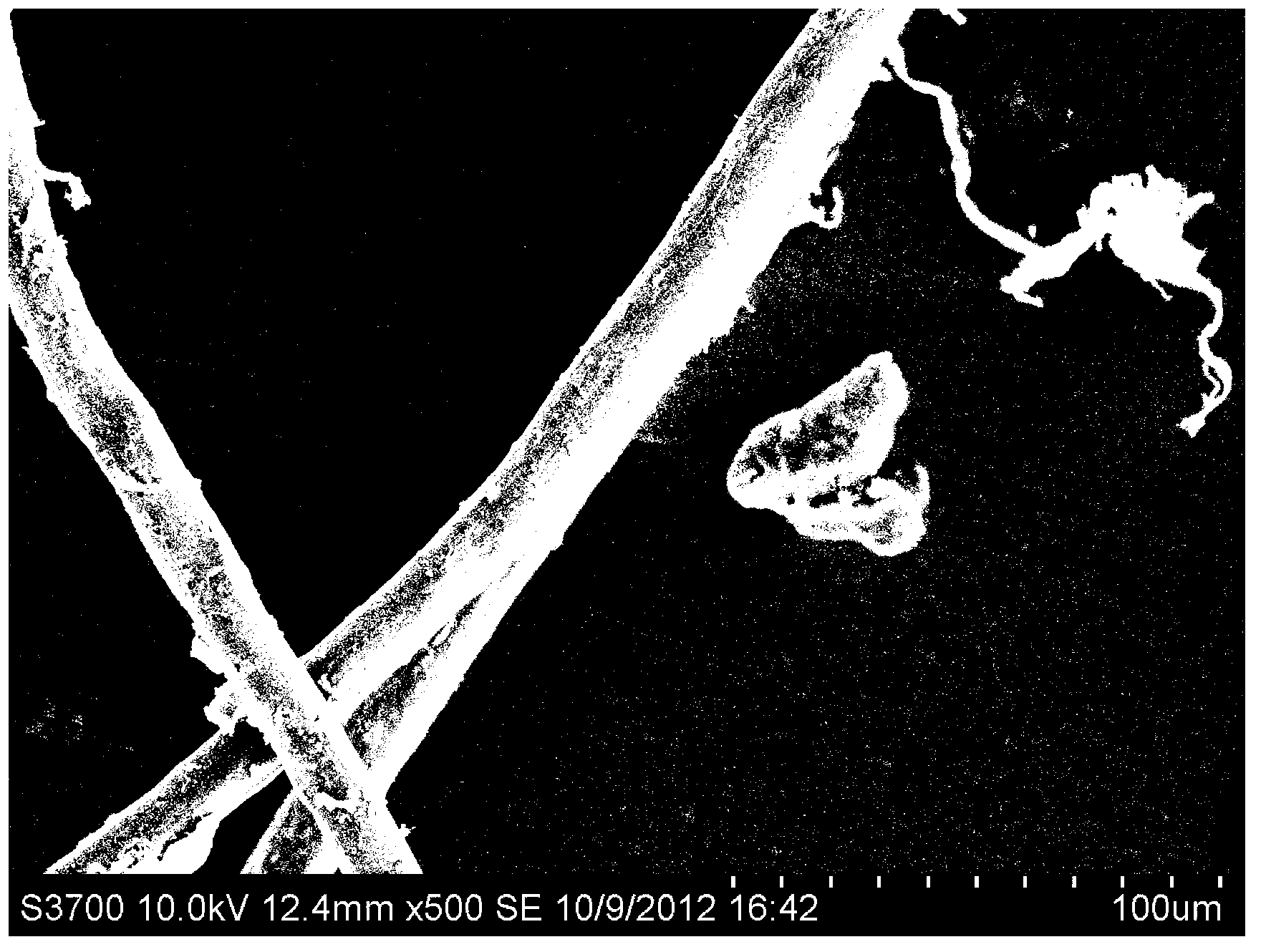

[0030] (1) The 1313 aramid chopped fiber and the 1313 aramid precipitated fiber were subjected to composite beating treatment, the beating concentrations were 15% and 10% by mass respectively, and the dilution water during beating was selected as deionized water; the 1313 aramid The 1313 aramid precipitated fiber adopts a two-stage composite beating process, and the current is respectively 20A in the first section, 22A in the second section, and 22A in the third section; 19A in the first paragraph, 19A in the second paragraph;

[0031] The initial beating degree of the 1313 aramid chopped fiber is 8°SR, and the beating degree rises to 14°SR after compound beating; the initial beating degree of the 1313 aramid precipitated fiber is 47°SR, after the compound beating The degree of beating is increased to 53°SR; the specific surface area of the 1313 aramid chopped fibers is increased by 113 times after composite beating.

[0032] (2) Use low-consistency hydraulic pulping equipm...

Embodiment 2

[0040] (1) The 1313 aramid chopped fiber and the 1313 aramid precipitated fiber were subjected to composite beating treatment, the beating concentration was 6% and 4% by mass respectively, and the dilution water during beating was selected as deionized water; the 1313 aramid The 1313 aramid precipitated fiber adopts a two-stage composite beating process, and the current is respectively 20A in the first section, 22A in the second section, and 22A in the third section; 19A in the first paragraph, 19A in the second paragraph;

[0041] The initial beating degree of the 1313 aramid chopped fiber is 8°SR, and the beating degree rises to 14°SR after compound beating; the initial beating degree of the 1313 aramid precipitated fiber is 47°SR, after the compound beating The degree of beating is increased to 53°SR; the specific surface area of the 1313 aramid chopped fibers is increased by 113 times after composite beating.

[0042] (2) Use low-consistency hydraulic pulping equipment ...

Embodiment 3

[0049] (1) The 1313 aramid chopped fiber and the 1313 aramid precipitated fiber are respectively subjected to composite beating treatment, the beating concentrations are respectively 24% and 15% by mass, and the dilution water during beating is selected as deionized water; the 1313 aramid The 1313 aramid precipitated fiber adopts a two-stage composite beating process, and the current is respectively 20A in the first section, 22A in the second section, and 22A in the third section; 19A in the first paragraph, 19A in the second paragraph;

[0050] The initial beating degree of the 1313 aramid chopped fiber is 8°SR, and the beating degree rises to 14°SR after compound beating; the initial beating degree of the 1313 aramid precipitated fiber is 47°SR, after the compound beating The degree of beating is increased to 53°SR; the specific surface area of the 1313 aramid chopped fibers is increased by 113 times after composite beating.

[0051] (2) Use low-consistency hydraulic pulp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com