Preparation method and application of nano iron-based polyether sulfone (PES) organic-inorganic composite material

An inorganic composite material and nano-iron technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult recovery and regeneration of nanoparticles, poor stability, and easy oxidation. Achieve long-lasting and efficient repair ability, low cost, and cost-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 : the preparation method of nanometer zero-valent iron particle, this embodiment is the contrast test of the inventive method, and specific content is as follows:

[0035] (1) Weigh 8.3406 grams of FeSO 4 .7H 2 O powder was then transferred to a clean beaker filled with deionized water, and magnetically stirred to fully dissolve it, and the FeSO with a molar concentration of 0.15 M was prepared. 4 Solution 200 mL, spare;

[0036] (2) Weigh another 9.711 grams of KBH 4 powder, dissolved in deionized water, stirred with a glass rod for several minutes, and made into KBH with a molar concentration of 0.9 M 4 200 mL of the solution, then transferred to a 250 mL pear-shaped separatory funnel for later use;

[0037] (3) Put the solutions prepared in steps (1) and (2) and the required materials into the anaerobic box, and put the KBH 4 The pear-shaped separatory funnel of the solution was fixed on an iron stand, and nitrogen was passed through for 60 min to remo...

Embodiment 2

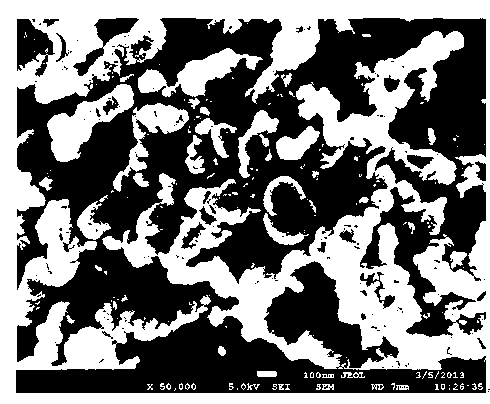

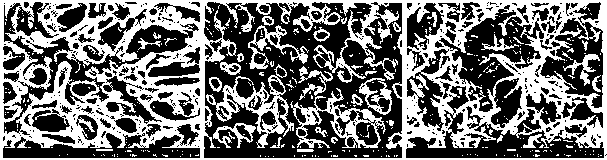

[0039] Example 2 : The preparation method of the nano iron-based PES organic-inorganic composite material, the specific content is as follows:

[0040] (1) First take a piece of PES microporous filter membrane (diameter, pore size and thickness are 5 cm, 0.45 μm and 100 μm, respectively) into a clean beaker filled with deionized water for 60 h, replace the deionized membrane every 12 h water;

[0041] (2) Prepare the MA functionalization solution consisting of a mixed aqueous solution of 25 wt% MA, 4 wt% polyethylene glycol 200 and 0.8 wt% ammonium persulfate, and then completely immerse the pretreated PES microporous filter membrane into the above functionalized The solution was taken out after 8 min, and the microporous membrane was sent to a vacuum drying oven at 75 °C for drying, and then the functionalized PES microporous membrane was soaked in deionized water for 36 h, and the deionized water was replaced every 12 h. The purpose is to remove unreacted monomers and oth...

Embodiment 3

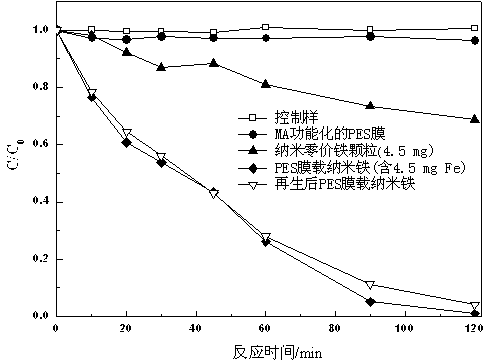

[0047] Example 3 : Investigation on the stability of nano-iron-based PES organic-inorganic composites and the degradation of metronidazole in water, the specific contents are as follows:

[0048] (1) Investigate the stability of nano-iron-based PES organic-inorganic composite materials: prepare nano-iron-based PES organic-inorganic composite materials according to the method described in Example 2, and then place them in deionized water with pH=3, and Record the color of the membrane at this time, and observe and record after intervals of 10 days, 20 days, 30 days and 60 days. After 30 days and 60 days, the color of the film surface hardly changed, and all were black, while the nanometer zero-valent iron particles prepared by the preparation method described in Example 1 were all oxidized after soaking in the above-mentioned deionized water for 2 h. It shows that the composite material prepared by reduction with green tea aqueous solution has high oxidation resistance in aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com