Control method of grain sizes of monodisperse silicon dioxide pellets

A technology of monodisperse silica microspheres and a control method, applied in the directions of silica and silicon oxide, can solve the problems of small particle size of silica microspheres and inability to realize continuous preparation, and achieve the effect of continuous preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

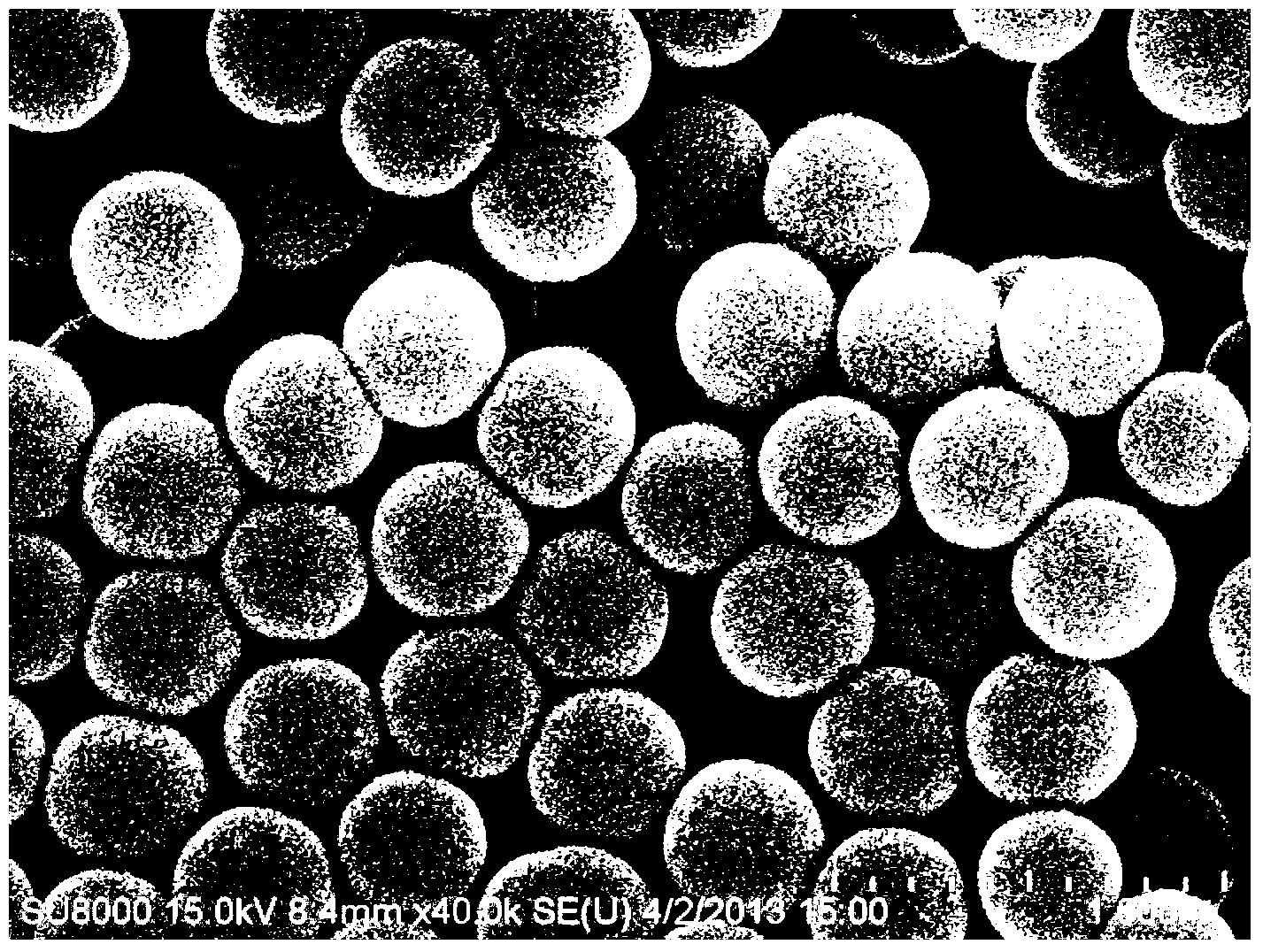

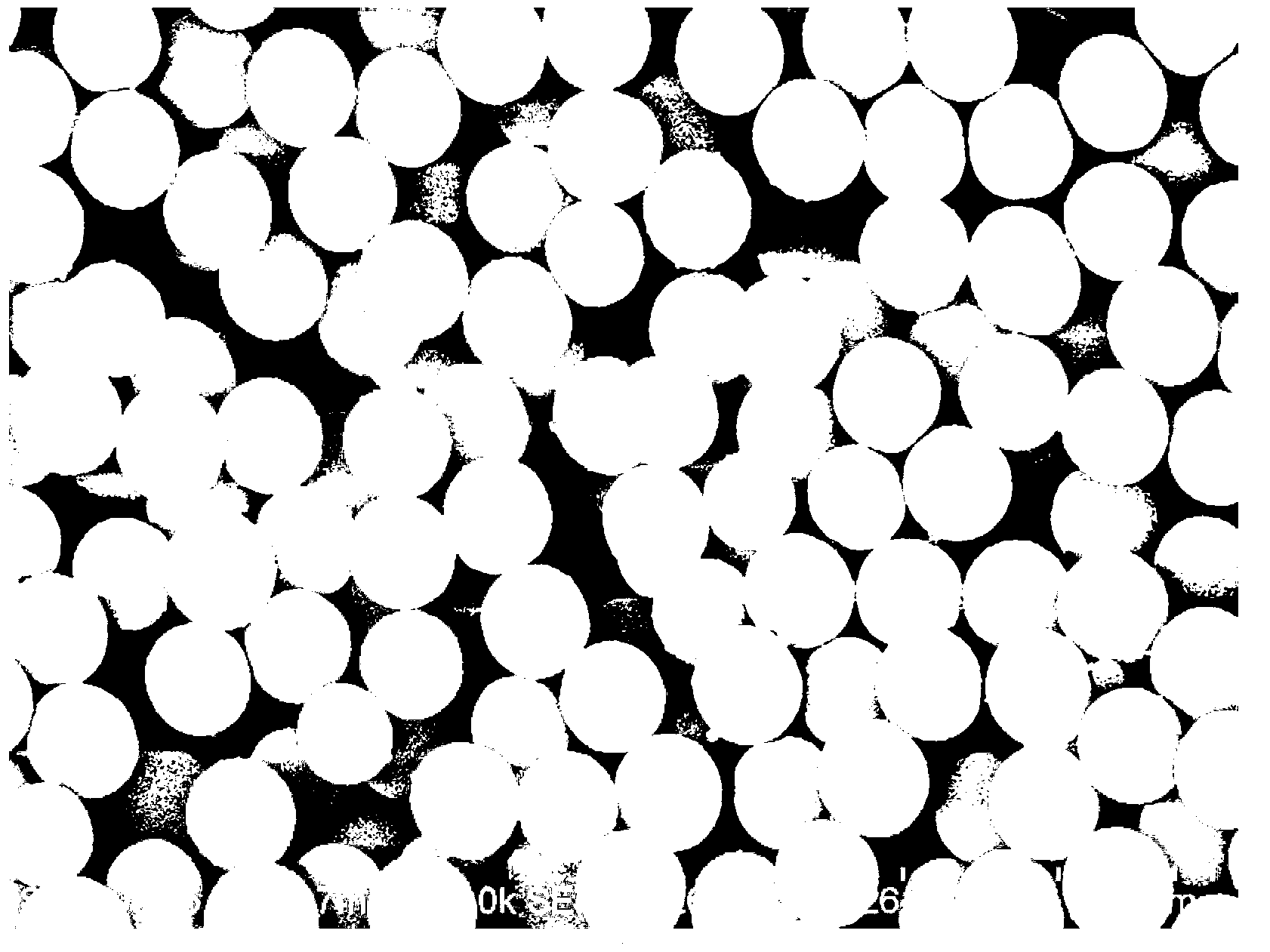

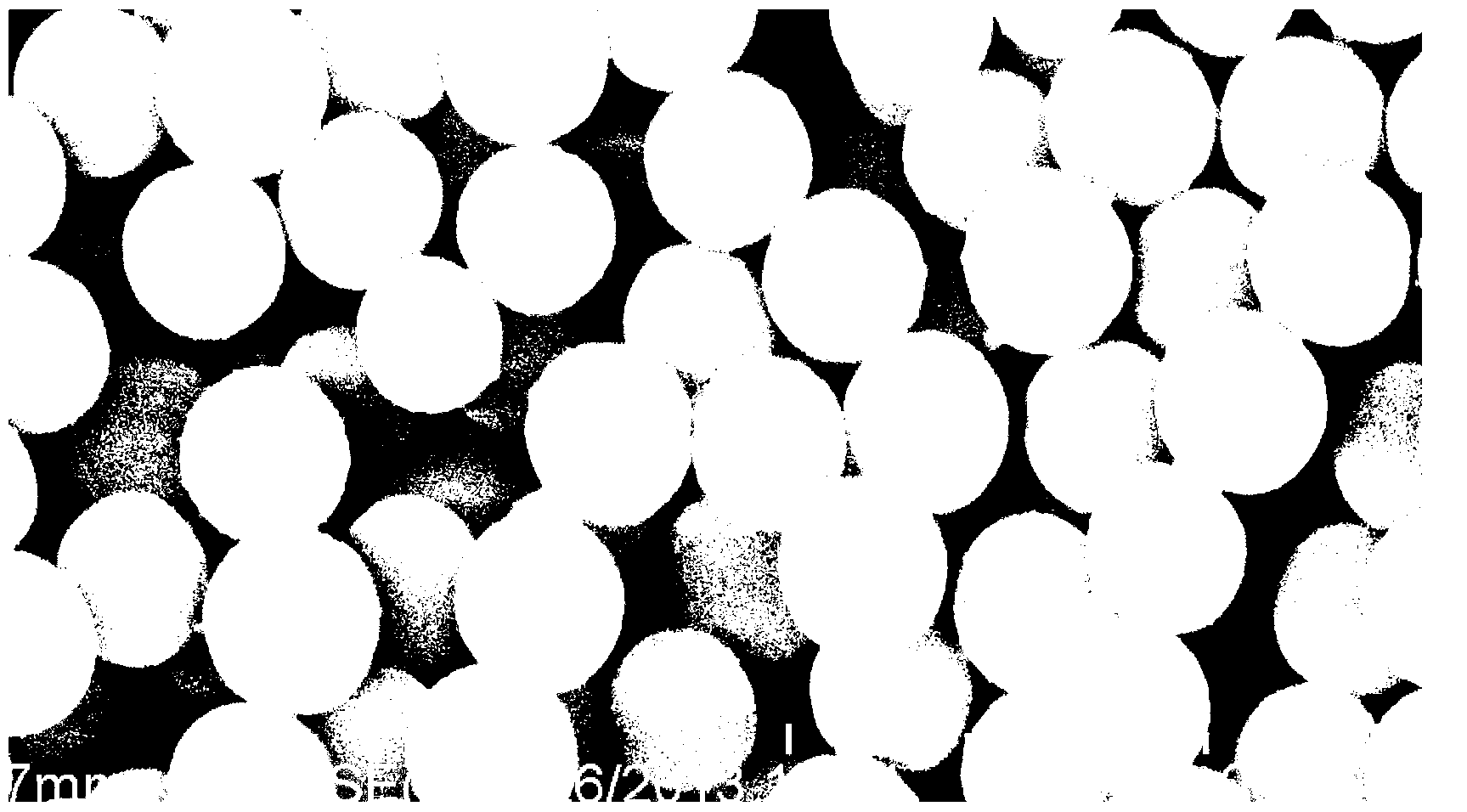

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the method for controlling the particle size of monodisperse silica microspheres in this embodiment is implemented according to the following steps:

[0018] 1. Adjust the temperature of the reactor to 0-78.4°C, add 148-152ml of absolute ethanol and 40-44ml of ammonia solution into the reactor, stir evenly to obtain a mixture of absolute ethanol and ammonia;

[0019] 2. Dissolve 16-16.2g of TEOS (tetraethyl orthosilicate) in 19-21ml of absolute ethanol, and then add it to a constant pressure dropping funnel to obtain a mixed solution of TEOS and absolute ethanol;

[0020] 3. Open the constant pressure dropping funnel and add the mixed solution of TEOS and absolute ethanol dropwise to the mixed solution of absolute ethanol and ammonia water in step 1. After reacting for 3 hours, the seed solution is obtained. Take a drop of the seed solution and measure it with a dynamic laser analyzer The particle diameter of silicon dioxide microspheres in the ...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment is different from Embodiment 1 in that the temperature of the reactor is adjusted to 60°C. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass concentration of the ammonia solution in step 1 is 25%. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com