Roof molding and its installation structure

A technology for trim strips and roofs, applied in vehicle parts, transportation and packaging, can solve the problems of complex production process, insufficient rigidity, heavy weight, etc., and achieve the effects of simple production process, high production efficiency and light weight of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

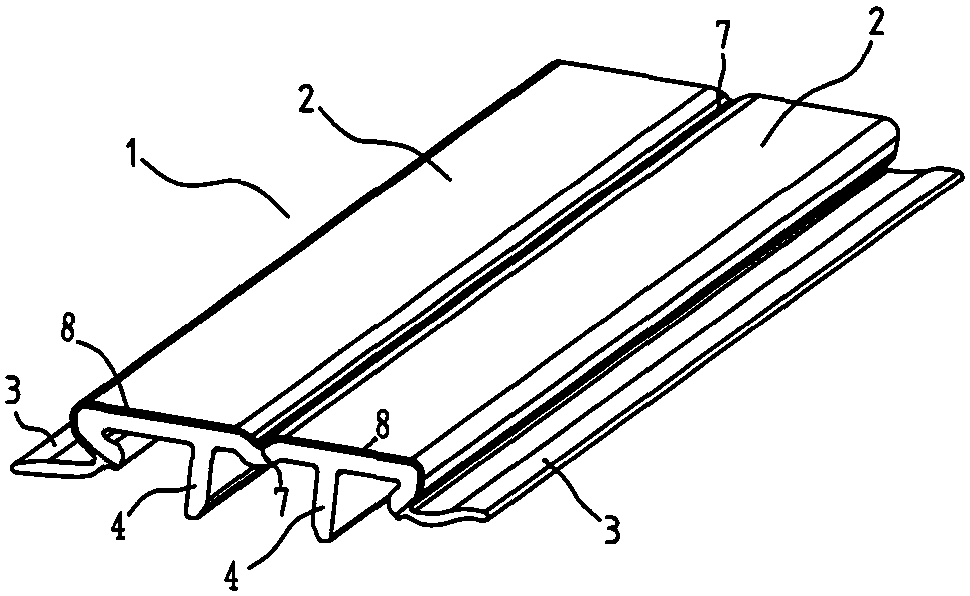

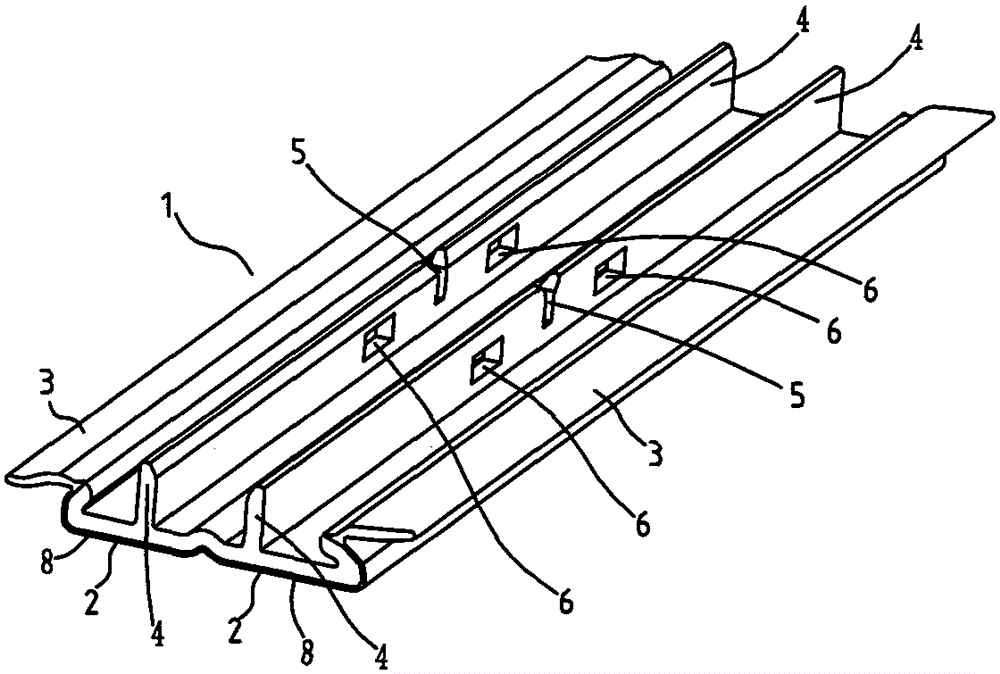

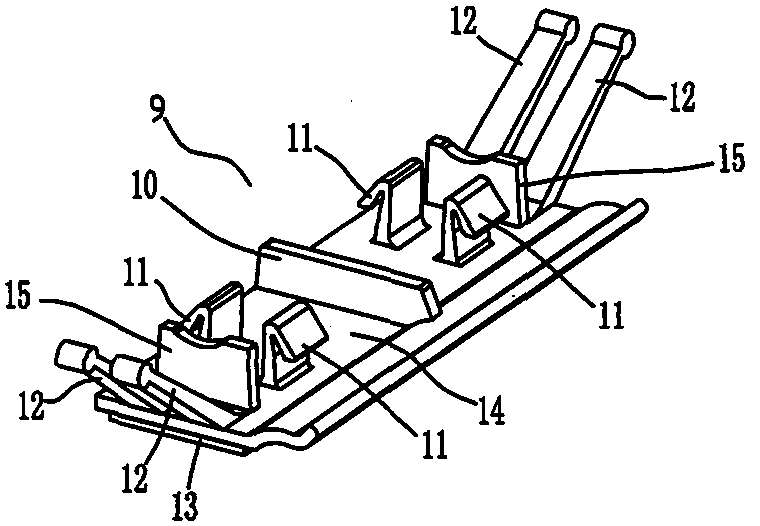

[0023] Such as figure 1 , figure 2 As shown, the roof trim 1 of the embodiment of the present invention includes a trim body with an appearance surface 2 and trim lips 3 located on both sides thereof for fitting with the roof surface or the side wall surface during installation. Two convex ribs 4 are arranged on the back of the top trim strip 1 along its longitudinal direction, and a plurality of gaps 5 are respectively opened in the two convex ribs 4 at the same longitudinal position according to the set distance a, and the convex ribs 4 located on both sides of each gap 5 Side holes 6 are provided on the side according to another set distance b.

[0024] Such as Figure 8 As shown, the set spacing a is 200mm to 300mm, the length of the general roof molding is about 1500mm, the number of notches 5 is 5 to 7, the other set spacing b is 30mm to 40mm, and the side hole 6 is a square hole , the side holes 6 are symmetrically distributed on both sides of the notch 5 . An arc-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com