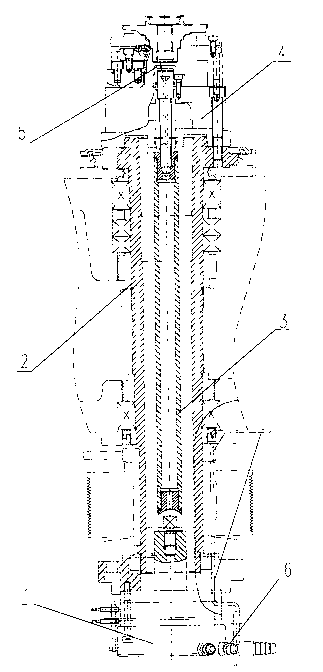

Lathe spindle center spraying cooling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Aiming at the present situation that the inner holes of parts processed by CNC lathes are mostly cooled by the processing end, the chip removal effect is not smooth, and the machining accuracy of the inner holes is not well maintained. , pipe joint 6 and other components, to achieve inner hole cooling from the clamping end of the part. The oil cylinder is assembled on the rear end of the lathe spindle through bolts, and the two ends of the hollow tie rod are connected with the hollow piston rod of the oil cylinder and the connecting rod in the center of the chuck in a threaded manner, and the sealing ring is used to seal the screw thread to prevent the cooling water from leaking into the main shaft ;The chuck is installed on the front end of the main shaft through bolts, the nozzle and the chuck are connected by bolts, and the sealing ring is used to seal the threaded part. The nozzles can be designed into different shapes according to the various needs of the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com