High-precision spiral wire winding machine

A wire winding machine, high-precision technology, applied in the field of communication equipment, can solve the problems that it is difficult to ensure the accuracy of the pitch of the winding spiral, and the form of the winding spiral is single.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

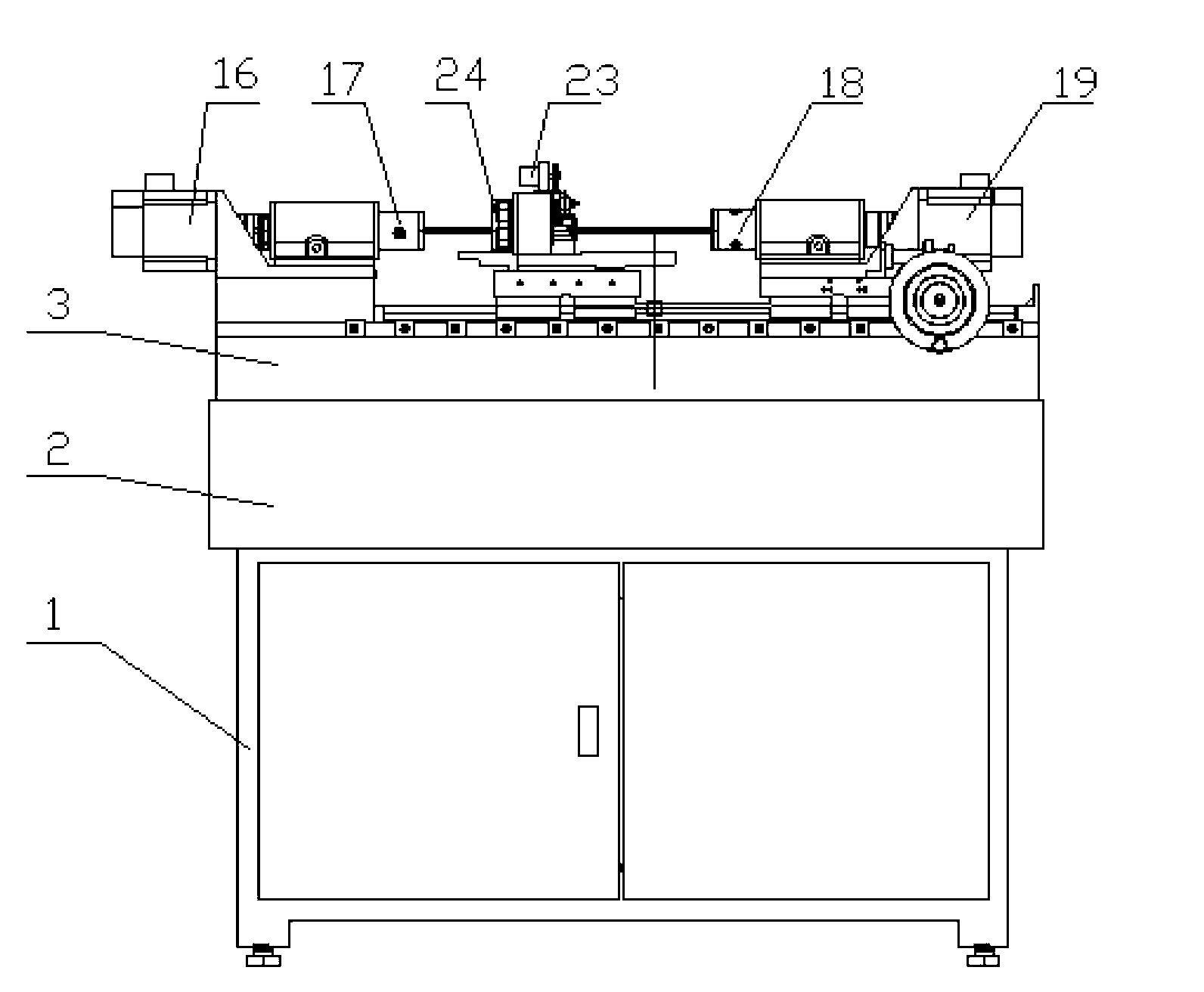

[0030] This embodiment is a high-precision spiral wire winding machine.

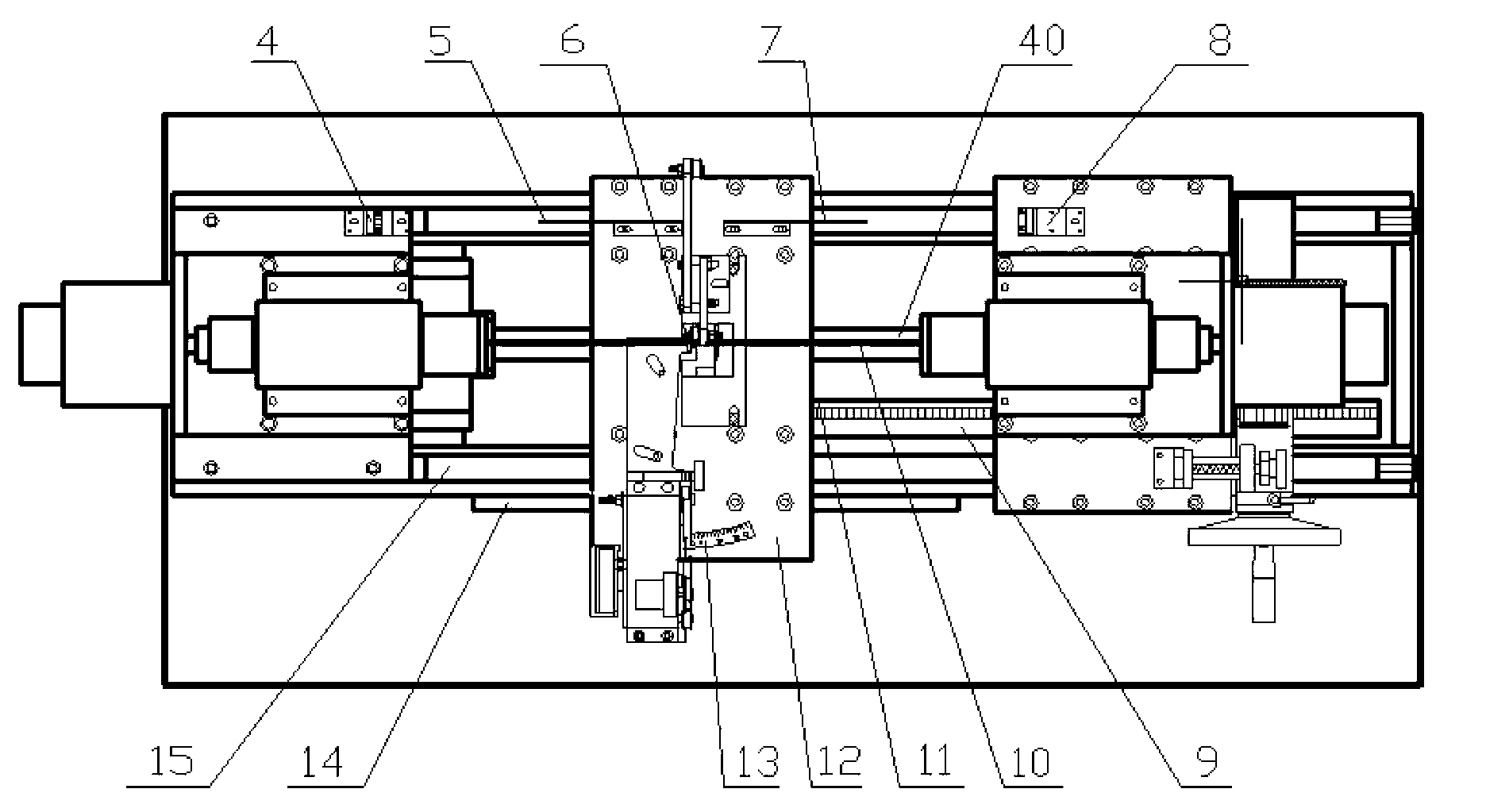

[0031] refer to figure 1 , figure 2 , image 3The high-precision spiral wire winding machine includes frame 1, stone base 2, support 3, wire winding mechanism, wire feeding mechanism, wire guide mechanism, worktable driving mechanism, locking mechanism, position detection system and electrical control system; The stone seat 2 is fixedly installed on the frame 1, the support 3 is located on the stone seat 2, and the wire winding mechanism, the workbench driving mechanism and the locking mechanism are installed on the support 3 in sequence. The wire feeding mechanism and the wire guiding mechanism are installed on the workbench 12 by screws.

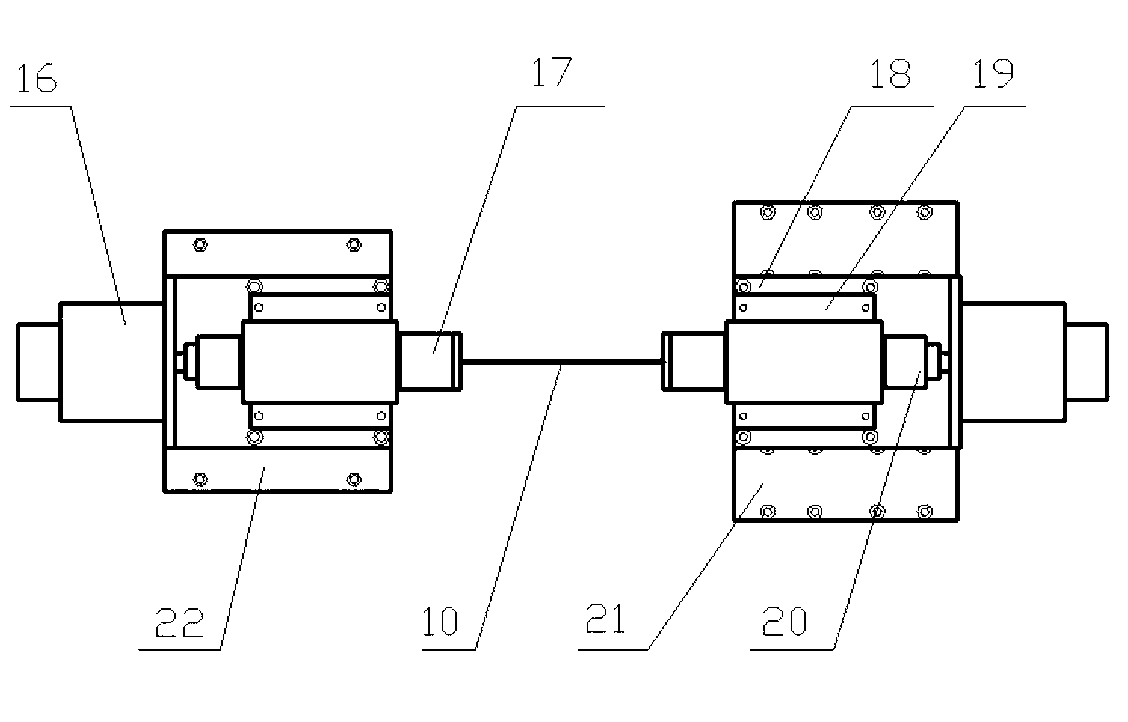

[0032] The wire winding mechanism includes a mandrel 10, two spindle drive servo motors 16, two spindle collets 17, a motor seat 18, a spindle seat 19, two elastic couplings 20, a mobile platform 21, a base 22, and a left stop Device 4, left limiter baffle 5, gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com