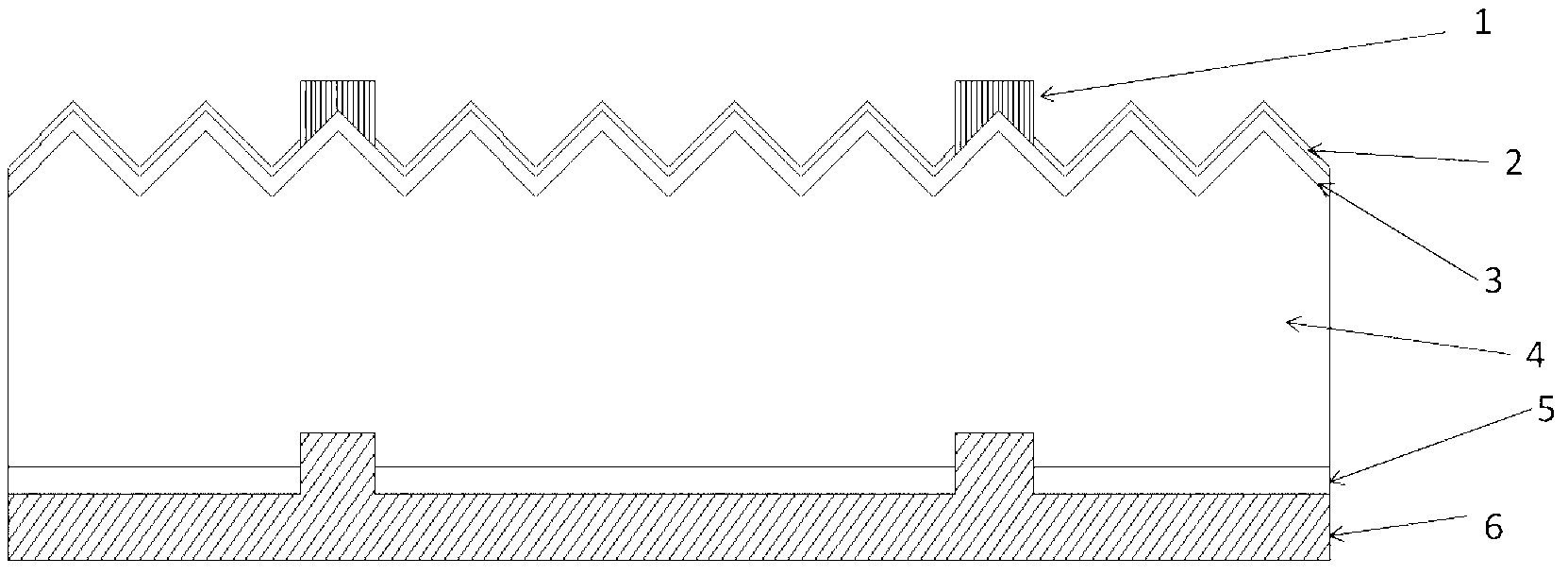

Crystalline silicon solar cell and method for manufacturing same

A technology of solar cells and crystalline silicon, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reduced conversion efficiency of cells, increased costs, and increased refractive index of silicon nitride films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Using a P-type monocrystalline silicon wafer as the base material (that is, the aforementioned substrate), the specific steps of the manufacturing method are as follows:

[0038] (1) P-type silicon wafers are damaged and textured, and cleaned;

[0039] (2) Tubular phosphorus diffusion, diffusion resistance 60ohm / sq;

[0040] (3) Wet edge cutting, and remove the PN junction on the back;

[0041] (4) Using HNO3 with a mass concentration of 69%, at 70°C for 10 minutes, grow a layer of silicon oxide on the upper surface of the silicon wafer with a thickness of 1-100nm (preferably 3-8nm);

[0042] (5) A silicon nitride film (as an anti-reflection film) is grown on the upper surface of silicon oxide by PECVD, with a thickness of 40-150nm (preferably 75nm);

[0043] (6) Print electrodes, sinter and test sorting;

[0044] (7) String welding battery slices;

[0045] (8) Laying, laminating, junction boxes, framing, and making finished components.

[0046] The solar cells are...

Embodiment 2

[0048] Using a P-type monocrystalline silicon wafer as the base material (that is, the aforementioned substrate), the specific steps of the manufacturing method are as follows:

[0049] (1) P-type silicon wafers are damaged and textured, and cleaned;

[0050] (2) Tubular phosphorus diffusion, diffusion resistance 60ohm / sq;

[0051] (3) Wet edge cutting, and remove the PN junction on the back;

[0052] (4) A layer of silicon oxide film is grown on the upper surface of the silicon wafer by PECVD, with a thickness of 10nm;

[0053] (5) A silicon nitride film (as an anti-reflection film) is grown on the upper surface of the silicon oxide film by PECVD, with a thickness of 70nm;

[0054] (6) Print electrodes, sinter and test sorting;

[0055] (7) String welding battery slices;

[0056] (8) Laying, laminating, junction boxes, framing, and making finished components.

[0057] The solar cells are made into modules, and the module materials are made of conventional commercial modu...

Embodiment 3

[0059] Using a P-type monocrystalline silicon wafer as the base material (that is, the aforementioned substrate), the specific steps of the manufacturing method are as follows:

[0060] (1) P-type silicon wafers are damaged and textured, and cleaned;

[0061] (2) Tubular phosphorus diffusion, diffusion resistance 60ohm / sq;

[0062] (3) Wet edge cutting, and remove the PN junction on the back;

[0063] (4) Using PECVD to grow a layer of amorphous silicon film on the upper surface of the silicon wafer with a thickness of 1-50nm (preferably 3-5nm);

[0064] (5) A silicon nitride film (as an anti-reflection film) is grown on the upper surface of silicon oxide by PECVD method, with a thickness of 75nm;

[0065] (6) Print electrodes, sinter and test sorting;

[0066] (7) String welding battery slices;

[0067] (8) Laying, laminating, junction boxes, framing, and making finished components.

[0068]The solar cells are made into modules, and the module materials are made of conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com