Four-point bending test device for full-size metal composite tube

A metal clad pipe, four-point bending technology, applied in measuring devices, using stable bending force to test material strength, instruments, etc., can solve problems such as unreasonable design, affecting detection accuracy, single structure and function, etc. Operational application, full-featured, simple-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

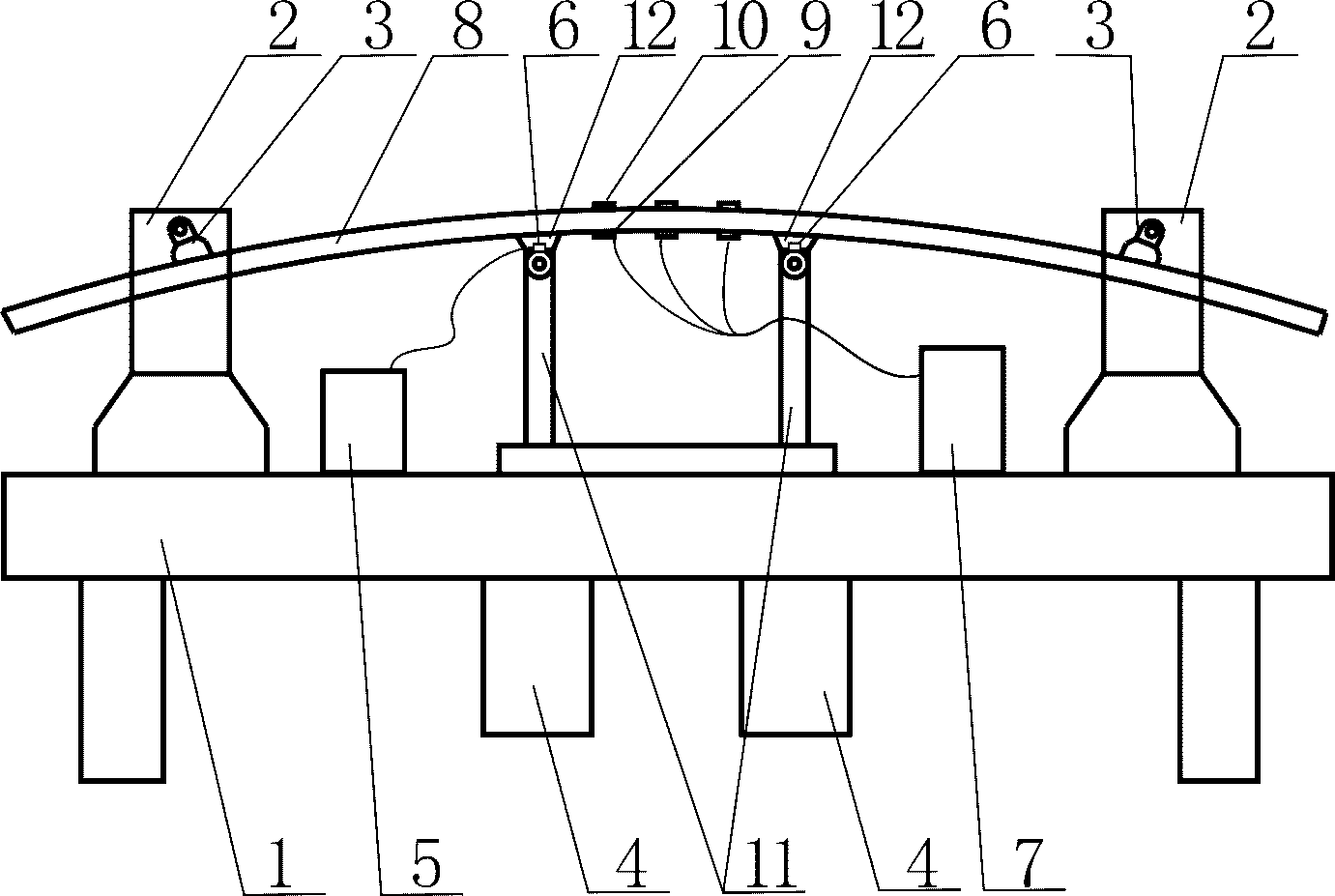

[0015] Such as figure 1 As shown, the full-scale metal composite pipe four-point bending test device is mainly composed of a base 1, two load support columns 2, a metal composite pipe clamp to be tested 3, two loading cylinders 4, a controller 5, a sensor 6, a strain sheet and a strain gauge 7, the metal composite pipe clamp 3 to be tested is arranged on each load support column 2, and can rotate longitudinally relative to the load support column, and the two load support columns 2 are arranged on the base 1 and Located at both ends of the base 1, the two loading cylinders 4 are arranged on the base 1 and between the two load supporting columns 2, the distance between the two loading cylinders 4 and the adjacent load supporting columns 2 is equal, and the two loading cylinders 4 The distance between the oil cylinders 4 is adjustable, and the sensor 6 is used to transmit the pressure and stroke of the loading oil cylinder 4 to the controller 5 . There are three groups of strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com