No-load test device for overturning of pitch-variable gearbox

A no-load test and gearbox technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problem that the working conditions of the variable pitch gearbox 10 are too different, the pitch variable gearbox 10 cannot be turned over, and cannot meet the quality inspection and control requirements To achieve the effect of avoiding overflow waste and polluting the site environment, improving the efficiency of product testing, and reducing the cost of product testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

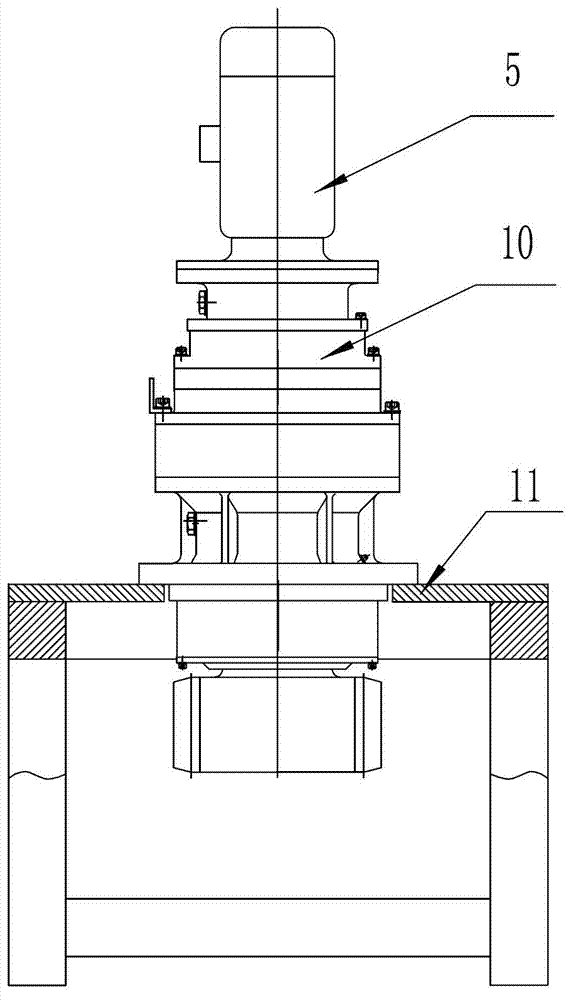

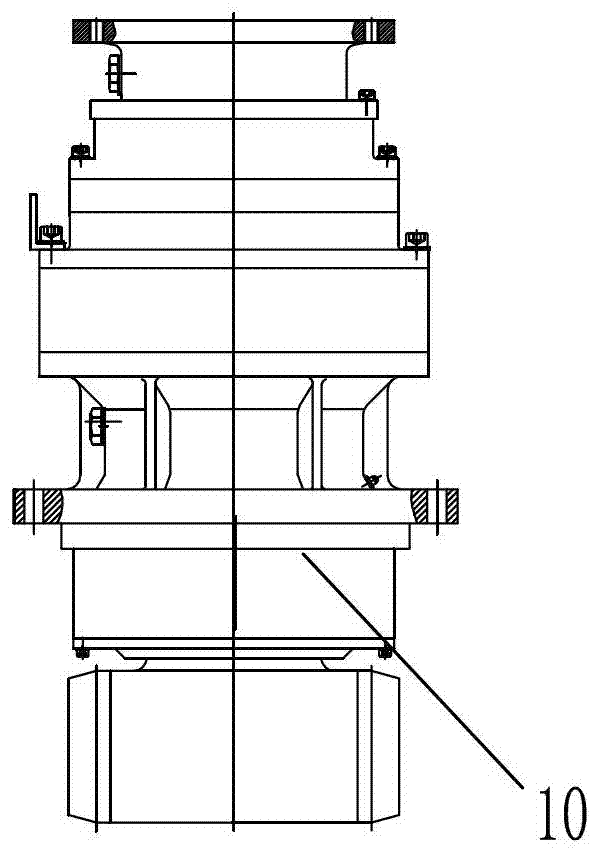

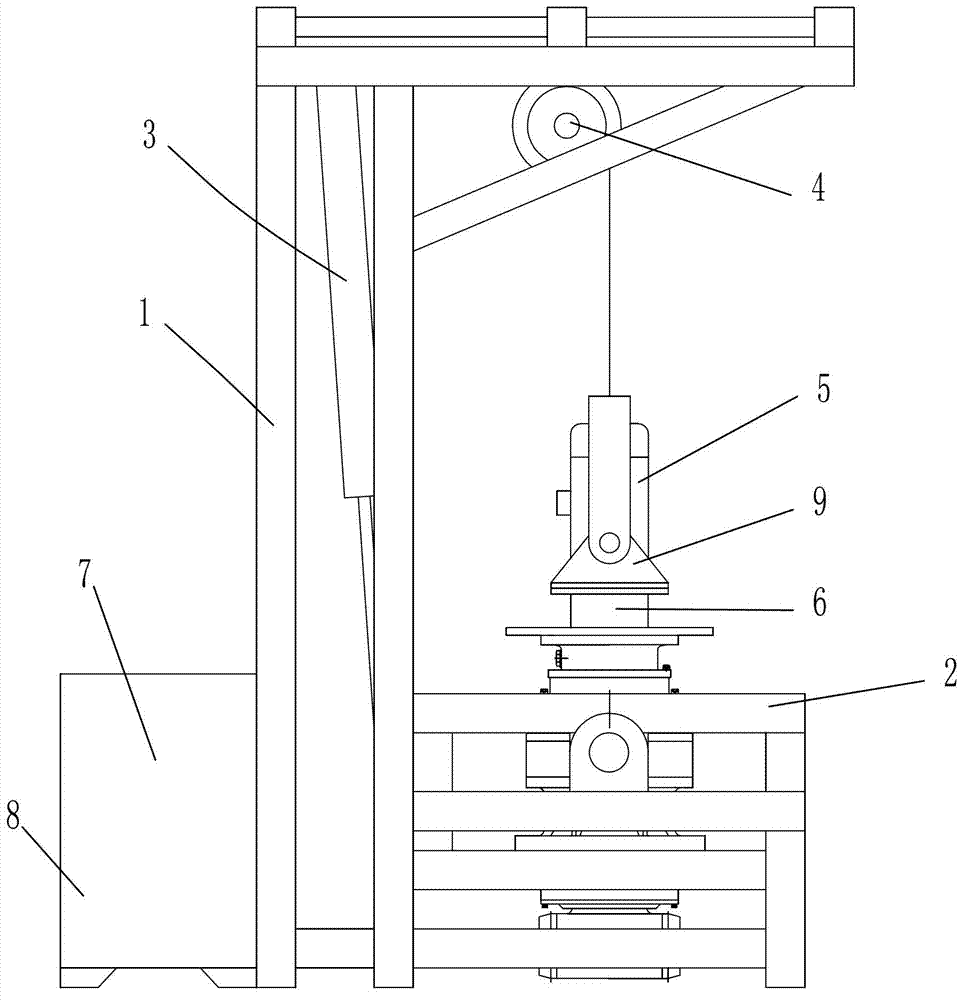

[0019] Such as image 3 —— Figure 5 The shown pitch gear box flipping no-load test device is mainly composed of a fixed frame 1, a flipping platform 2, a cylinder piston assembly 3, a balance crane 4 and a driving motor 5. The turning platform 2 is used for installing the pitch gearbox 10 . The piston cylinder assembly 3 is composed of a piston rod 3a, a cylinder body 3b and a piston arranged in the cylinder body 3b. The overturning platform 2 is hinged on the fixed frame 1 through the first hinge axis A. There are two first hinge axes A, located on the front and rear sides of the overturning platform 2 and centered on the left and right. The middle part of the overturning platform 2 can be around the first A hinge axis A rotates; the turning platform 2 is hinged to the lower end of the piston rod 3a through the second hinge axis B, the second hinge point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com