High temperature valve detecting and testing system

A test system and valve technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems affecting the core competitiveness of high-temperature valve products, the leakage and flow capacity of switch performance, and the inability to provide corresponding problems. Achieve the effect of wide test range, simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

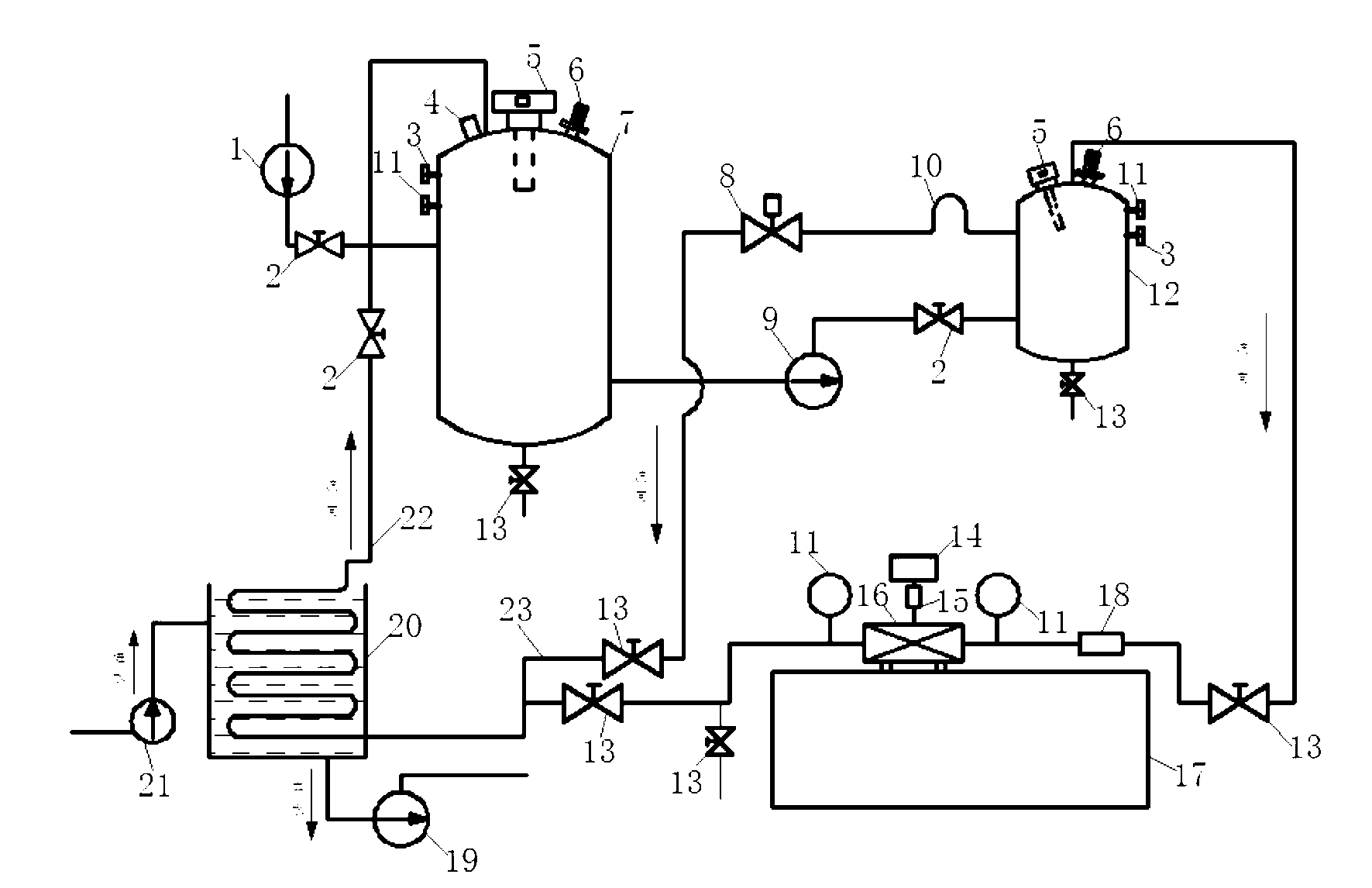

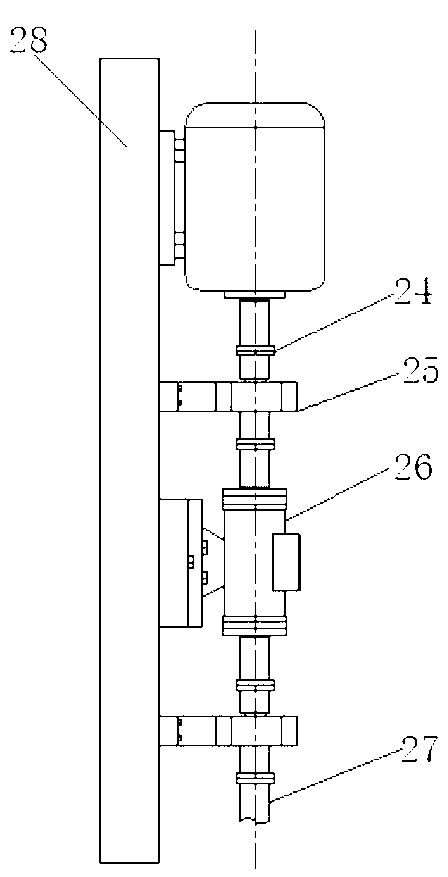

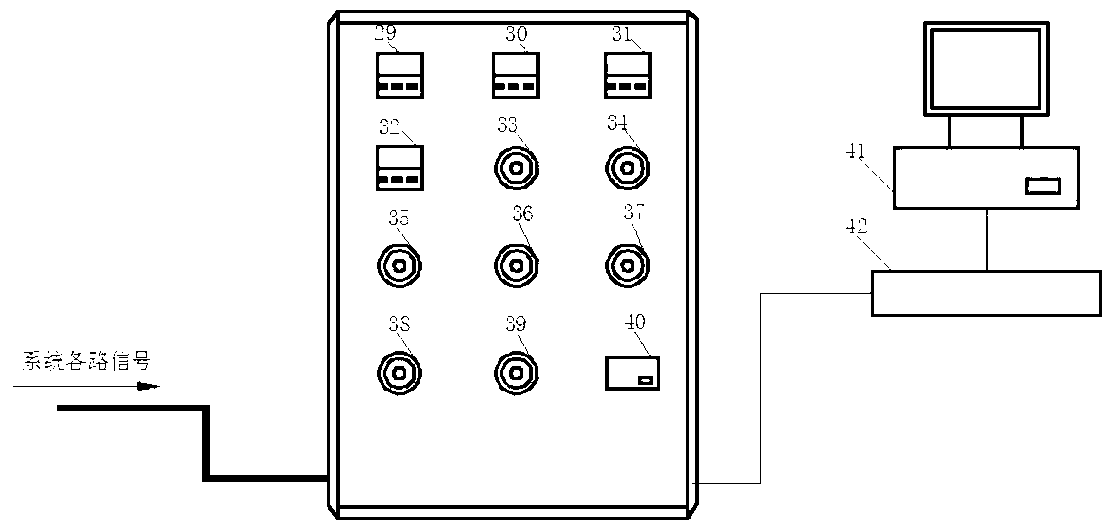

[0026] figure 1 shows a schematic structural diagram of an embodiment provided by the present invention, by figure 1 It can be seen that the high temperature valve detection test system provided in this embodiment includes an oil inlet pump 1, an oil storage tank 7, a pressure pump 9, a buffer tank 12, a detection device, a condensation device, a data acquisition system, and a control system. An electric heater 5, a pressure transmitter 11, a safety valve 6 and an exhaust valve 4 are installed on the top of the oil storage tank 7, a temperature sensor 3 is installed on the inner wall of the oil storage tank 7, and a stop valve 13 is connected to the bottom oil discharge pipe. The top of the oil storage tank is provided with a first oil inlet hole, and the side of the oil storage tank is provided with a second oil inlet hole, and the oil outlet of the oil inlet pump 1 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com