Ultrasonic film thickness measuring instrument and measuring method thereof

A measuring instrument, ultrasonic technology, applied in the direction of measuring device, using ultrasonic/sonic wave/infrasonic wave, instrument, etc., can solve the problems of limited thickness range and inaccurate side measurement of oil film thickness, and achieve the effect of simple circuit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

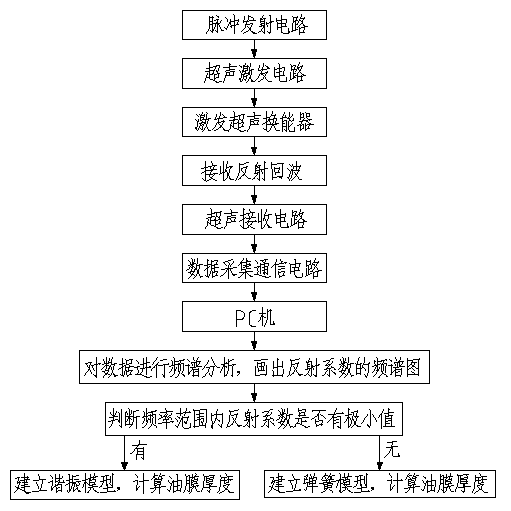

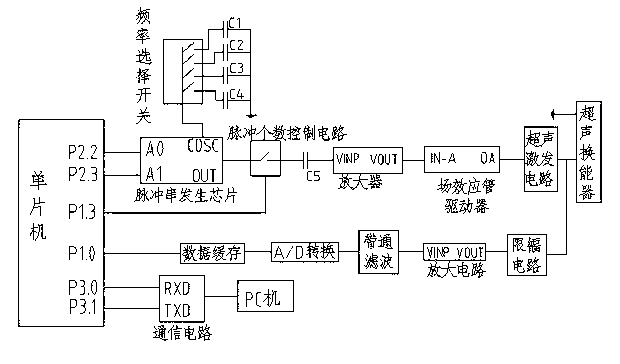

[0039] Below in conjunction with accompanying drawing, the technical scheme of invention is further described:

[0040] The thickness of the oil film in different mechanical equipment is different. In order to distinguish, the concepts of thin oil film and thick oil film are defined in the present invention. Generally, when the thickness of the oil film is much smaller than the wavelength of the incident wave, it is called a thin oil film, otherwise it is called a thick oil film. Two calculation models are established for different oil film thicknesses, the resonance model is used for thick oil film, and the spring model is used otherwise. This is the theoretical model to finally calculate the oil film thickness.

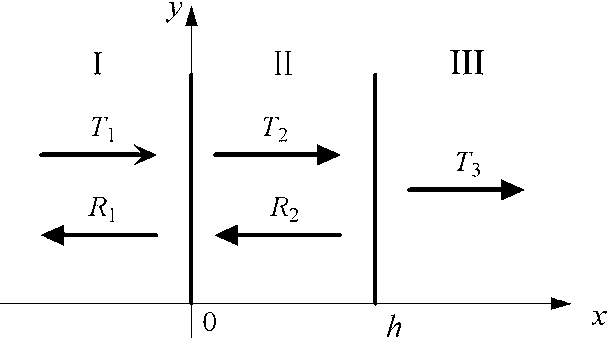

[0041] Such as figure 1 As shown, the oil film to be tested (that is, medium II) is located between mediums I and III, and the figure shows the propagation of ultrasonic waves in the three-layer medium.

[0042] When the oil film is thick, a resonance model is est...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com