Simple and reliable water injection device for water-assisted injection molding

An injection molding, water-assisted technology, which is applied in the direction of valve operation/release device, valve device, valve lift, etc., can solve the problems of deviation of high-pressure water forward direction, difficulty of water injection, increase of manufacturing cost of water needle processing, etc., to achieve a solution Anti-rust problems, reliable action, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

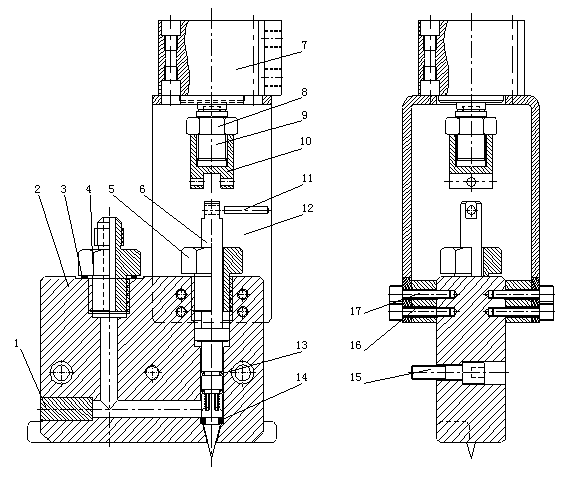

[0009] The present invention will be further described below in conjunction with accompanying drawing:

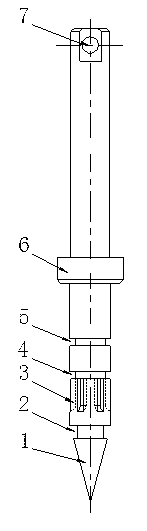

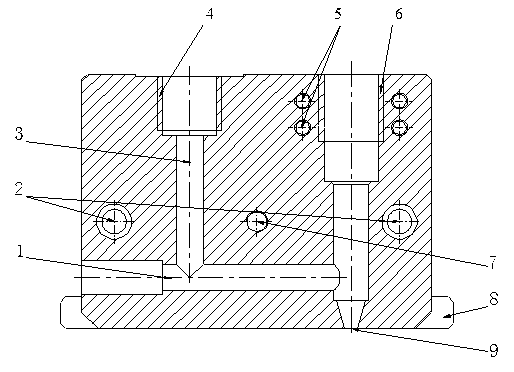

[0010] Assembly drawing of water injection device figure 1 shown. The water injection device includes plug (1), valve body (2), sealing gasket (3), variable diameter high-pressure water pipe joint (4), flange (5), valve core (6), SDA thin cylinder (7), Cylinder joint (8), adjusting nut (9), coupling (10), coupling pin (11), cylinder bracket (12), O-ring (13), rectangular sealing ring (14), needle valve installation Bolts (15), cylinder bracket gaskets (16), cylinder bracket mounting screws (17). With the valve body (2) as the main body, the variable-diameter high-pressure water joint (4), flange (5), valve core (6), etc. are directly installed on the valve body; the cylinder (7) is fixed by the cylinder bracket (12), The valve core is controlled by being connected with the valve core through the cylinder joint (8), the coupling (10) and the connecting pin (11).

[0011]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com