A cylindrical self-balancing eccentric shaft for jaw crusher

A technology of jaw crusher and eccentric shaft, which is applied in the direction of eccentric shaft, grain processing, inertial force compensation, etc., can solve the problems of jaw crusher mechanism complexity, noise, increased power consumption, etc., to eliminate double power consumption factors and reduce Manufacturing cost and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

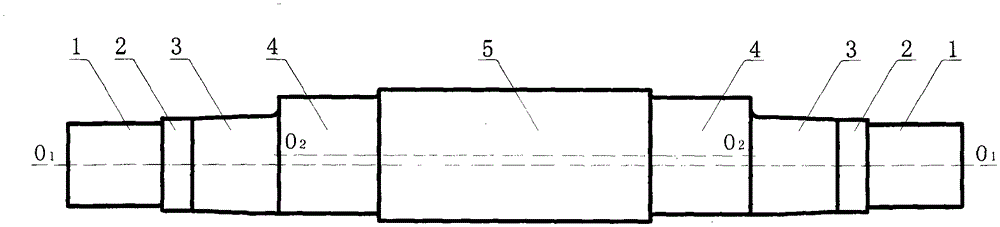

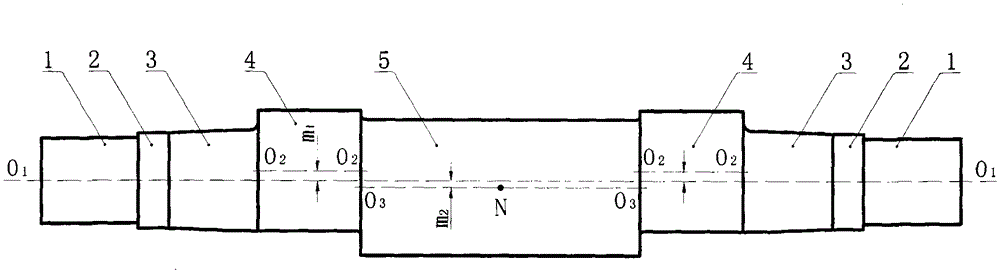

[0036] Embodiment 1: as figure 2 As shown, a cylindrical self-balancing eccentric shaft used for jaw crushers is symmetrically connected to the eccentric bearing gear 4, the concentric bearing gear 3, the locking gear 2 and the reference gear on both sides of the connecting gear 5 from the inside to the outside. Gear 1 is composed together, and the axes of concentric bearing gear 3, locking gear 2 and reference gear 1 on both sides are located on the rotation centerline O of the whole shaft 1 -O 1 On the top, the center of the eccentric bearing gear 4 on both sides is located on the eccentric centerline O of the whole shaft 2 -O 2 Above; the axis line of the connecting gear 5 is located in the eccentric bearing gear 4 relative to the rotation center line O 1 -O 1 The opposite side of the eccentricity, that is, the mass center point N of the connecting gear 5 is located on the eccentric opposite side of the eccentric bearing gear 4, and the eccentric moment of the connecti...

Embodiment 2

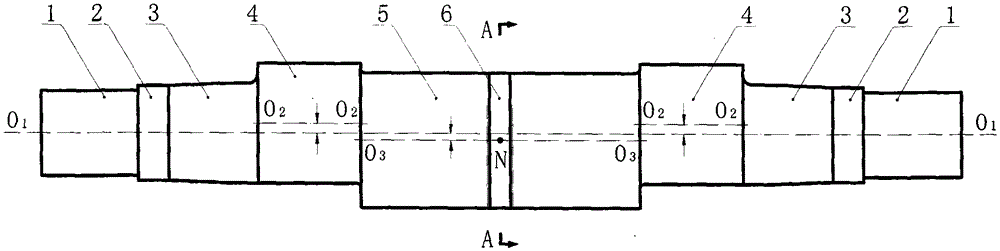

[0037] Embodiment 2: as image 3 with Figure 4 As shown, the connecting gear 5 is provided with an in-line fine-tuning screw hole 6 passing through it, and the center line of the fine-tuning screw hole 6 is located on the plane where the eccentric center line of the eccentric bearing gear 4 and the rotation center line of the concentric bearing gear 3 are located. ; The fine-tuning screw hole 6 is provided with a pair of torque fine-tuning screws threadedly matched with it, and the pair of torque fine-tuning screws includes two adjusting screws 7 and stop screws 8 that cooperate with each other one after the other and abut together. All the other are with embodiment 1.

Embodiment 3

[0038] Embodiment 3: as Figure 5 with Image 6 As shown, the connecting gear 5 is provided with a cross-shaped fine-tuning screw assembly that runs through it, and the cross-shaped fine-tuning screw assembly includes two fine-tuning screw holes 6 that are perpendicular to each other but do not intersect; A pair of torque trimmer screws. The pair of torque fine-tuning screws includes two adjusting screws 7 and stop screws 8 that cooperate with each other and abut together one after the other.

[0039] The fine-tuning screw holes 6 all run through the center of the connecting gear radially, and the fine-tuning screw hole directions of the fine-tuning screw holes 6 are all perpendicular to the eccentric center line of the eccentric bearing gear 4 . The center line of one of the fine-tuning screw holes 6 is located on the plane where the eccentric center line of the eccentric bearing rack 4 and the rotation center line of the concentric bearing rack 3 are located.

[0040] All t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com