High-temperature heat transfer oil composition

A heat transfer oil and composition technology, which is applied in the field of mineral oil type high temperature heat transfer oil composition, can solve the problems of high price of synthetic high temperature heat transfer oil, cracking and polymerization of heating system, and restrictions on large-scale popularization and application, and achieve low cost, Good heat transfer effect and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

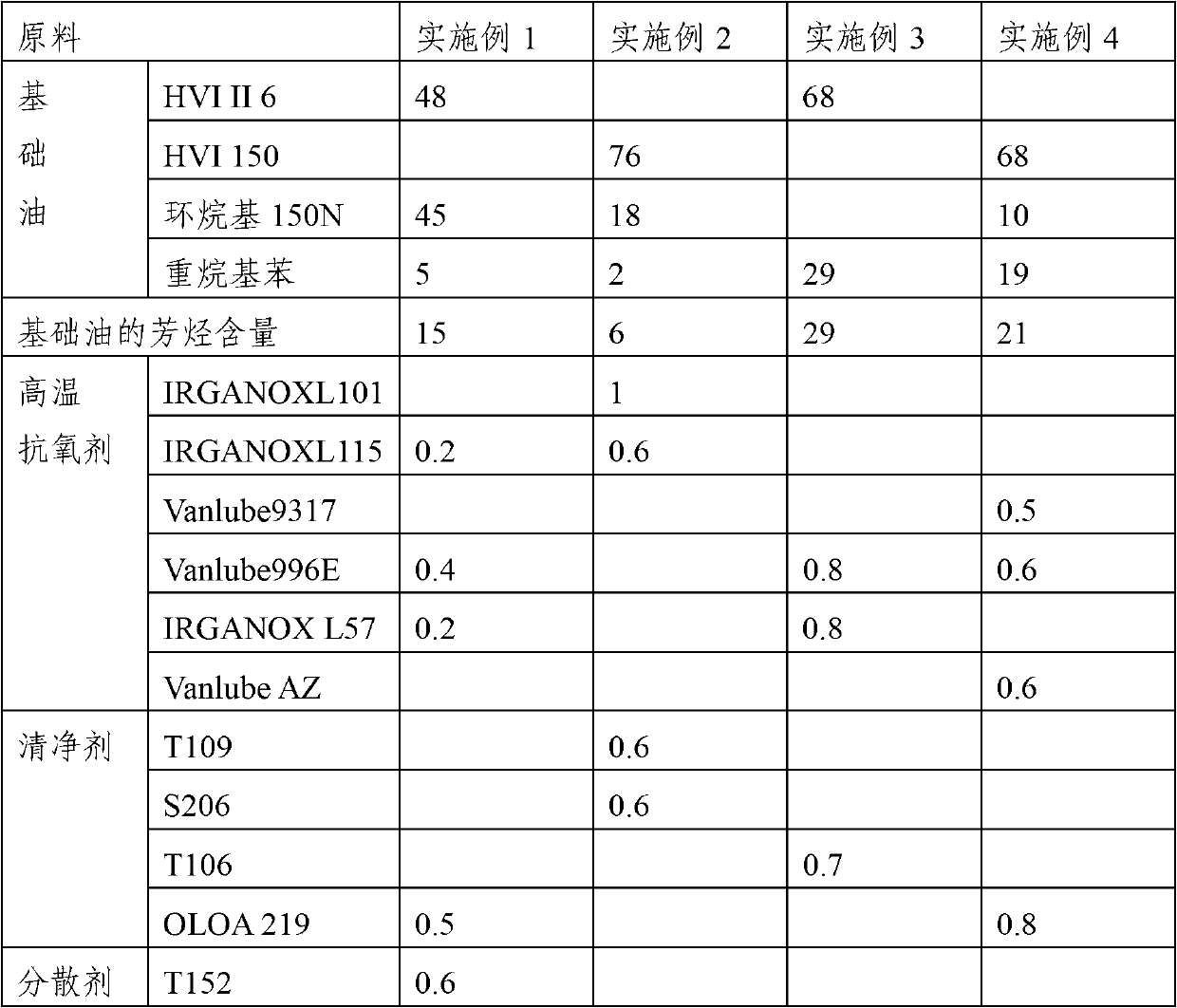

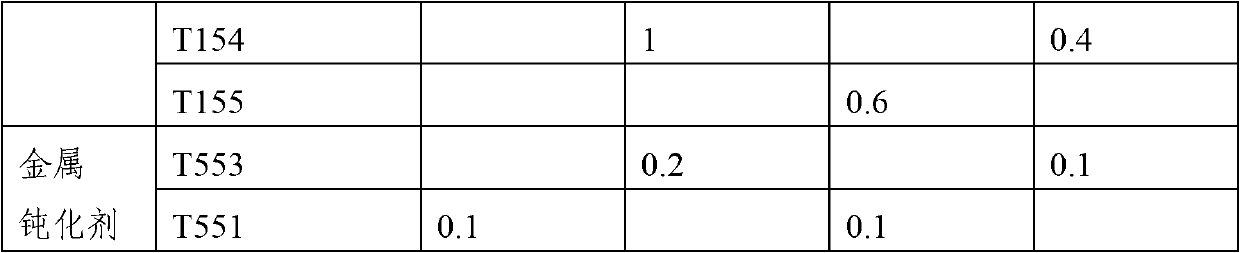

[0036] The components of a high-temperature heat-conducting oil composition in the embodiment are shown in Table 1. The preparation process includes but is not limited to the following: first heat the base oil to 80°C, then add antioxidants according to the proportion and stir until uniform and transparent, and then Then add detergent, dispersant and metal deactivator respectively, and stir evenly.

[0037] Table 1

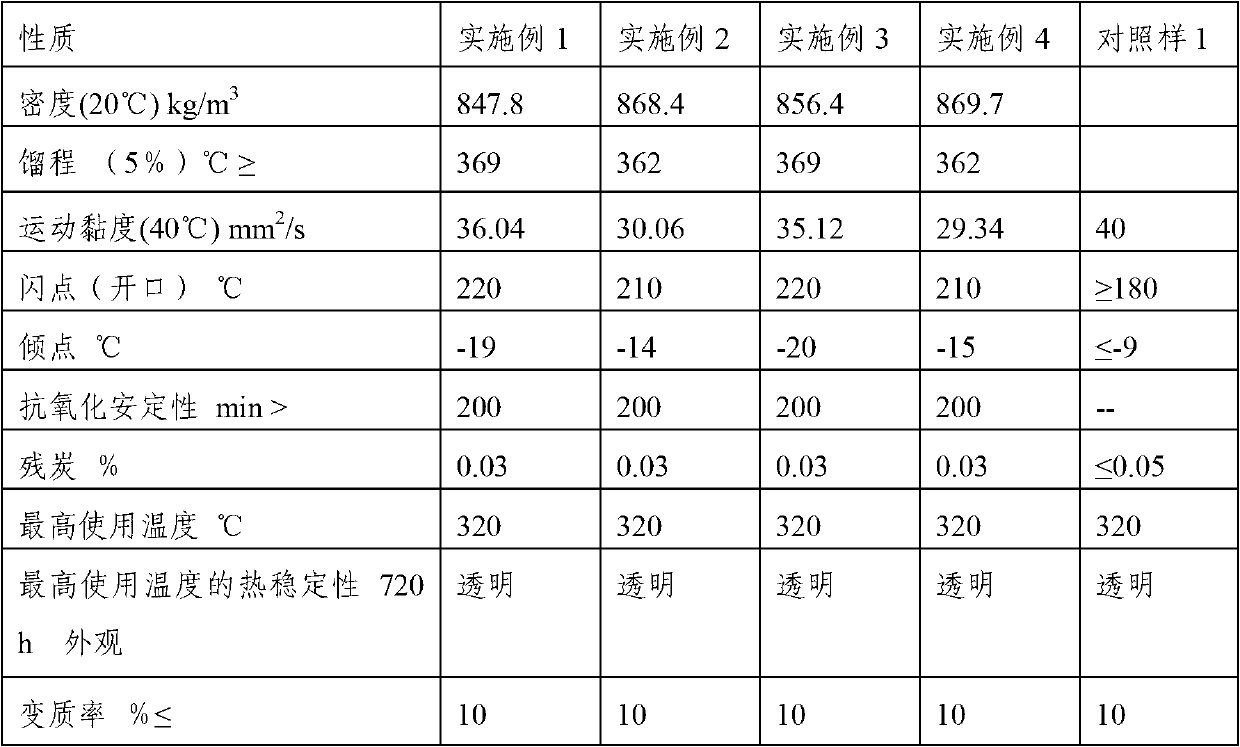

[0038]

[0039]

[0040] Among them, the base oil HVI Ⅱ6 (purchased from Shanghai Gaoqiao Petrochemical Company) in the above examples has a viscosity of 37.04mm at 40°C 2 / s, HVI 150 (purchased from Maoming Petrochemical Company) has a viscosity of 30.89mm at 40°C 2 / s, naphthenic base oil 150N (purchased from Yingkou Kunlun Lubricating Oil Co., Ltd.) has a viscosity of 27.49mm at 40°C 2 / s, heavy alkylbenzene (purchased from Chevron Oronite, USA) has a viscosity of 20.55mm at 40°C 2 / s.

[0041] IRGANOX L115, IRGANOX L101, and IRGANOX L57 were purchase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com