Iron oxide yellow viscosity reduction method

An iron oxide yellow and viscosity technology, applied in chemical instruments and methods, inorganic pigment treatment, dyeing physical treatment, etc., can solve the problems of limited use occasions, affect the performance of use, excessive heavy metal ions, etc., to broaden the application field, product viscosity reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

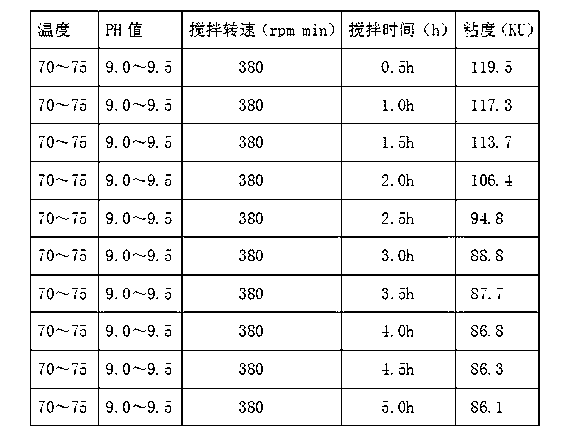

[0023] In a stainless steel reaction barrel with a volume of 10 liters, add about 3 liters of tap water in advance, and then turn on the strong agitator for stirring, and then add 600 grams (dry basis) of iron oxide yellow 313 filter cake material directly produced in the industry in batches , to form a slurry, continue to add water to control the concentration of the slurry at about 12%, and raise the temperature of the material liquid to 70-75 degrees and keep it, and then slowly add 10% concentration of dilute alkali to control the pH at 9.0-9.5 In between, control the stirring speed at 350-400 rpm. After stirring for 1 hour, start to take out a small amount of sample (about 10 grams) for analysis and testing, then continue stirring, and then take samples every 1 hour. The sample taken out was filtered and rinsed up to the standard, and the filter cake was placed in an oven at 110°C for drying, and then pulverized by a micro pulverizer for analysis and testing. The comparis...

Embodiment 2

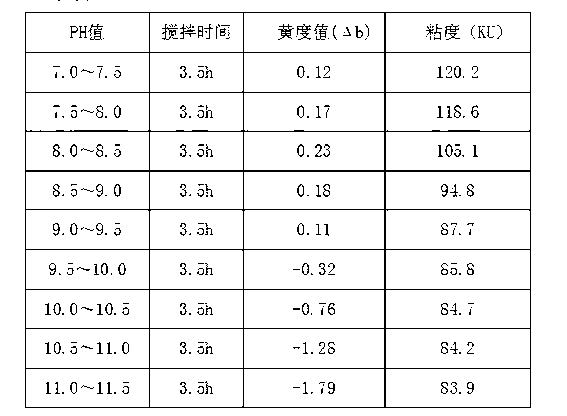

[0029] Under the condition that the other conditions of Example 1 were constant, the different pH values of the reaction solution were controlled respectively, and after stirring for 3.5 hours, the samples were taken out for analysis and testing. The effect of PH value on the yellow tone (yellowness value) and viscosity of iron yellow pigment is as follows:

[0030] Table 2:

[0031] The iron oxide yellow 313# filter cake material before treatment is directly dried and crushed as a standard sample, and the color and shade of the test are:

[0032]

[0033] It can be seen from Table 2 that, under the condition that other conditions remain unchanged, with the continuous increase of the pH of the reaction system, the viscosity value of Tiehuang 313# gradually decreases, and the decrease is most obvious when the pH is 9.0 to 9.5; when the pH When the value is greater than 9.5, the viscosity value of iron oxide yellow decreases more and more slowly as the pH value continues t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com