Treatment method of Congo red dye wastewater

A dye wastewater and treatment method technology, which is applied in the field of Congo red dye wastewater treatment, can solve the problems of affecting cell activity, easy to be biodegraded, poor mass transfer performance, etc., and achieve strong adsorption, low price, and low comprehensive utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

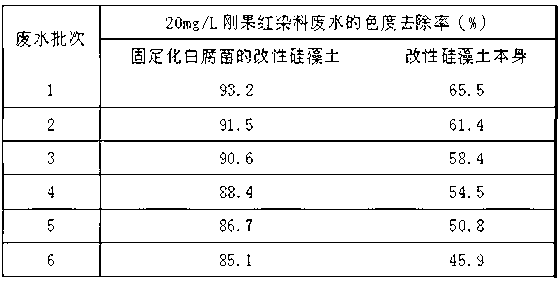

Image

Examples

Embodiment 1

[0022] Embodiment 1: a kind of method of processing Congo red dye of embodiment 1, comprises the following steps:

[0023] (1) Modification of diatomite:

[0024] Pass 100 g of purified diatomite through a 200-mesh sieve, then add a hydrochloric acid solution with a molar concentration of 5 mol / L to soak it completely, treat it at a constant temperature of 60°C for 70 minutes, and keep stirring; Wash the soil several times with distilled water until the pH value of the filtrate is neutral; dry the filtered diatomaceous earth at a temperature of 105°C, take it out and place it in a desiccator for later use; weigh 120g of crystalline aluminum chloride, and add a concentration of In a 10% sodium hydroxide solution, make the final molar ratio of crystalline aluminum chloride and sodium hydroxide 2:1, stir to make it uniform, let it stand for 15 hours, weigh 60g of diatomite in the desiccator and add it to the solution , stir to mix evenly, filter and dry at a temperature of 105°C...

Embodiment 2

[0032] Embodiment 2: a kind of method of processing Congo red dyestuff of embodiment 2, comprises the following steps:

[0033] (1) Modification of diatomite:

[0034] Pass 120 g of the modified diatomite through a 200-mesh sieve, then add a hydrochloric acid solution with a molar concentration of 5.5 mol / L to soak it completely, treat it at a constant temperature of 70°C for 80 minutes, and keep stirring; Celite was washed several times with distilled water until the pH of the filtrate was neutral. Dry the filtered diatomaceous earth at a temperature of 105°C, weigh 130g of crystalline aluminum chloride, and add it to a sodium hydroxide solution with a concentration of 12%, so that the final molar ratio of crystalline aluminum chloride to sodium hydroxide is 2: 1. Stir to make it even, let it stand for 20 hours, weigh 70g of diatomaceous earth in the desiccator and add it to the solution, stir to mix evenly, filter and dry at a temperature of 105°C; then place it in a muffle...

Embodiment 3

[0042] Embodiment 3: a kind of method of processing Congo red dyestuff of embodiment 3, comprises the following steps:

[0043] (1) Modification of diatomite:

[0044] Pass 150 g of the modified diatomite through a 200-mesh sieve, then add a hydrochloric acid solution with a molar concentration of 6 mol / L to soak it completely, treat it at a constant temperature of 80°C for 90 minutes, and keep stirring; Wash diatomite with distilled water several times until the pH value of the filtrate is neutral; dry the filtered diatomite at a temperature of 105°C, weigh 140g of crystalline aluminum chloride, and add 15% sodium hydroxide In the solution, make the final molar ratio of crystalline aluminum chloride and sodium hydroxide to be 2:1, stir to make it uniform, let it stand for 24 hours, weigh 80 g of diatomaceous earth spare in the desiccator and add it to the solution, stir to make it evenly mixed , dried at a temperature of 105°C after filtering; then baked in a muffle furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com