Amino-methyl dual-functionalized SBA-15 material as well as preparation method and application thereof

A bifunctional, amino-based technology, applied in the direction of crystalline aluminosilicate zeolite, can solve the problems of cumbersome steps and uneven distribution of functional groups, and achieves the treatment of hyperbilirubinemia, the preparation method is simple and feasible, and the high The effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Under magnetic stirring, add 4g of commercially available surfactant P123 (triblock copolymer P123) and 8.8g of inorganic salt KCl into 120mL of 2mol / L hydrochloric acid solution, stir until a transparent solution is formed, then add 9.0mL of TEOS and 0.932 mL of aminopropylmethyldiethoxysilane. The reaction mixture was stirred at a constant temperature for 24 hours at 40°C, then transferred to a polytetrafluoroethylene autoclave, and hydrothermally treated in an oven at 100°C for 48 hours. After cooling, the resulting product was repeatedly washed with deionized water and ethanol. After suction filtration and washing, dry at 80°C, and finally extract the product with ethanol for 48 hours in a Soxhlet extractor to remove surfactant P123, and dry at 80°C to obtain short-channel, functional group Amino-methyl bifunctional SBA-15 mesoporous material with evenly distributed clusters, and its texture parameters and pore lengths are shown in Table 1.

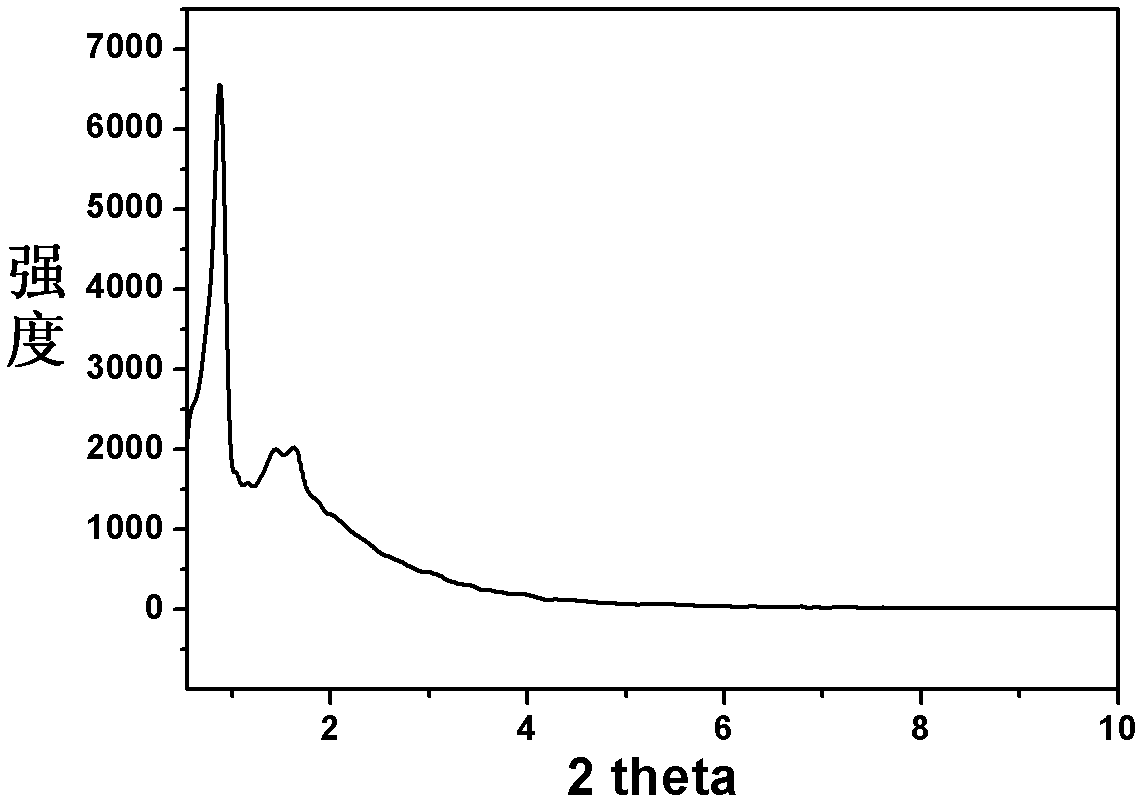

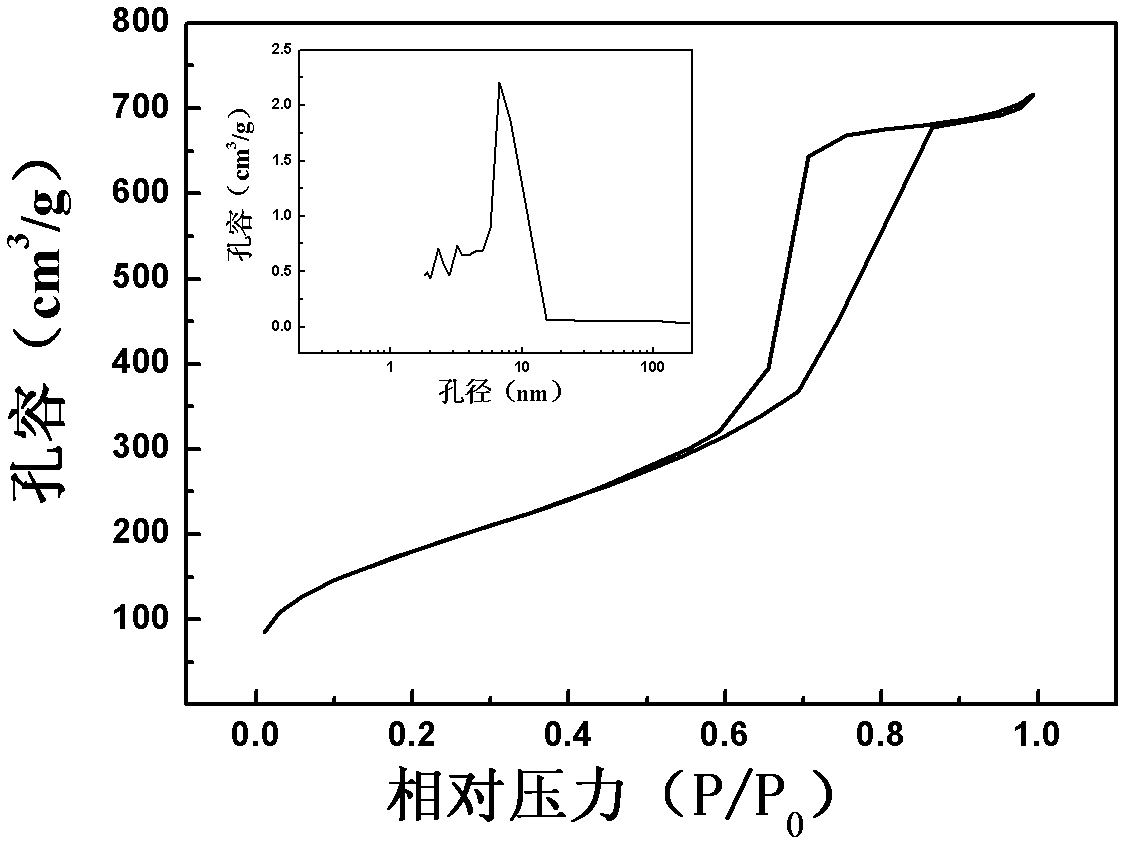

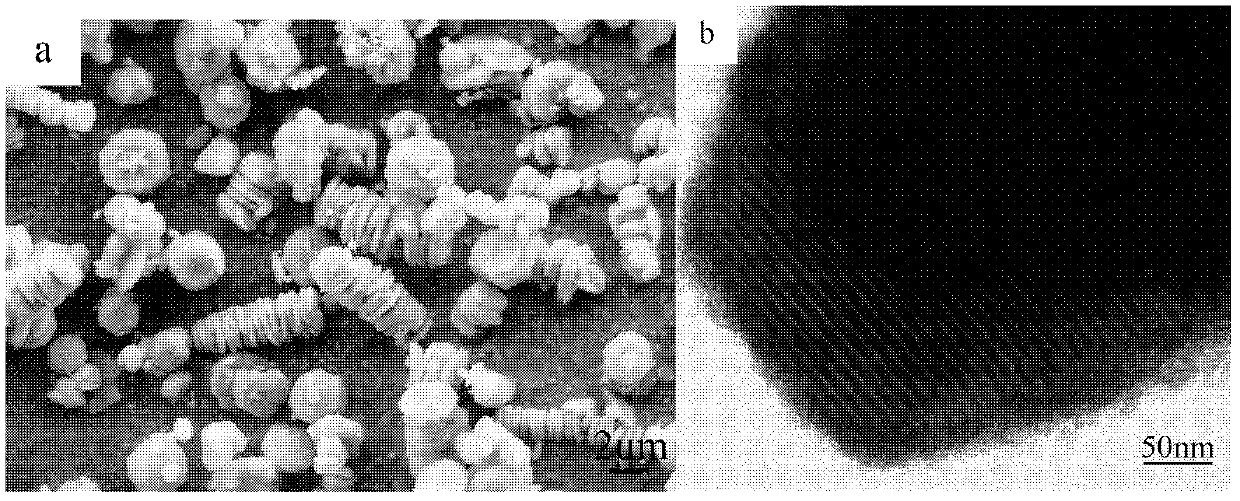

[0038] figure 1 is th...

Embodiment 2

[0050] Under magnetic stirring, add 4g of surfactant P123 and 13.2g of inorganic salt KCl into 120mL of 2mol / L hydrochloric acid solution, stir well until a transparent solution is formed, then add 9.0mL of TEOS and 0.932mL of aminopropylmethyldiethyl Oxysilane. The reaction mixture was stirred at a constant temperature for 24 hours under the condition of 40° C., then transferred into a polytetrafluoroethylene autoclave, and left standing in an oven at 100° C. for hydrothermal treatment for 24 hours. After cooling, the obtained product was repeatedly suction-filtered and washed with deionized water and ethanol, dried at 80°C, and finally the product was extracted with ethanol in a Soxhlet extractor for 48 hours to remove surfactant P123, at 80°C The amino-methyl bifunctional SBA-15 material with short channels and uniform distribution of functional groups can be obtained by drying at the bottom. The texture parameters and channel lengths are shown in Table 1.

[0051] Figur...

Embodiment 3

[0053] Under magnetic stirring, add 4g of surfactant P123 and 8.8g of inorganic salt KCl into 120mL of 2mol / L hydrochloric acid solution, stir well until a transparent solution is formed, then add 8.5mL of TEOS and 1.398mL of aminopropylmethyldiethyl Oxysilane. The reaction mixture was stirred at a constant temperature for 24 hours under the condition of 40° C., then transferred into a polytetrafluoroethylene autoclave, and left standing in an oven at 100° C. for hydrothermal treatment for 72 hours. After cooling, the obtained product was repeatedly suction-filtered and washed with deionized water and ethanol, and dried at 80°C. Finally, the product was extracted with ethanol for 48 hours in a Soxhlet extractor to remove the surfactant P123, 80 The amino-methyl bifunctional SBA-15 material with short channels and uniform distribution of functional groups can be obtained by drying at ℃. The texture parameters and channel lengths are shown in Table 1.

[0054] Figure 5 It is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com