Novel trailer control valve

A control valve, a new type of technology, applied in the direction of control valve and air release valve, brake, brake components, etc., can solve the problems of insufficient braking force, complex manufacturing process, air leakage, etc., to improve reliability and durability, manufacturing Low cost and high ventilation flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

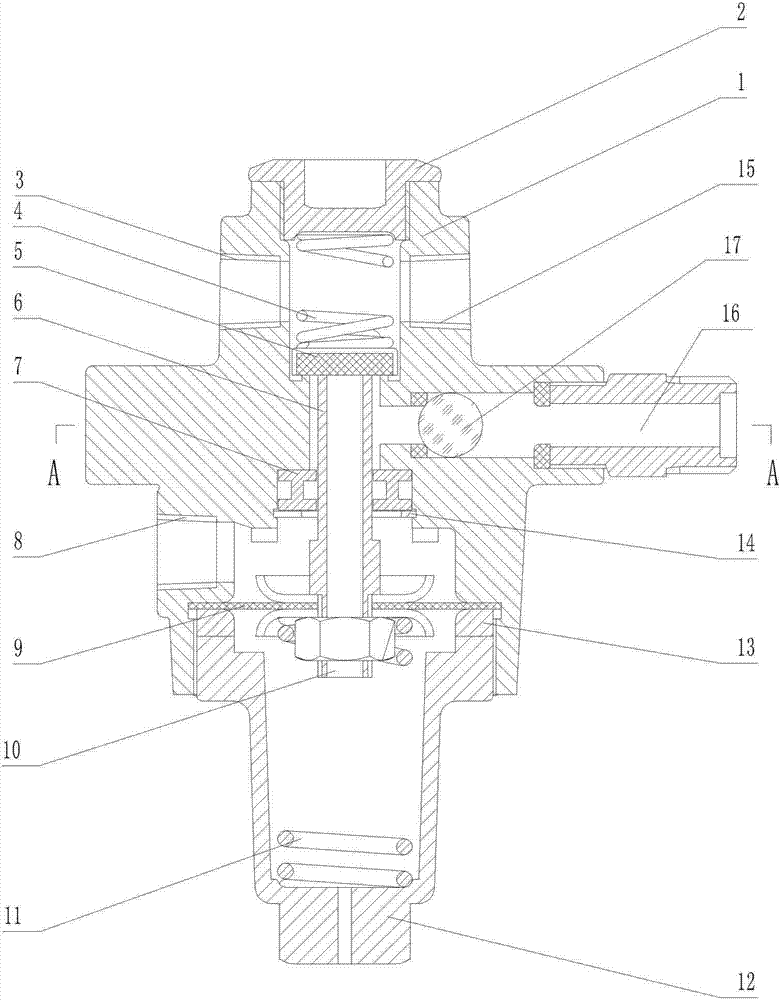

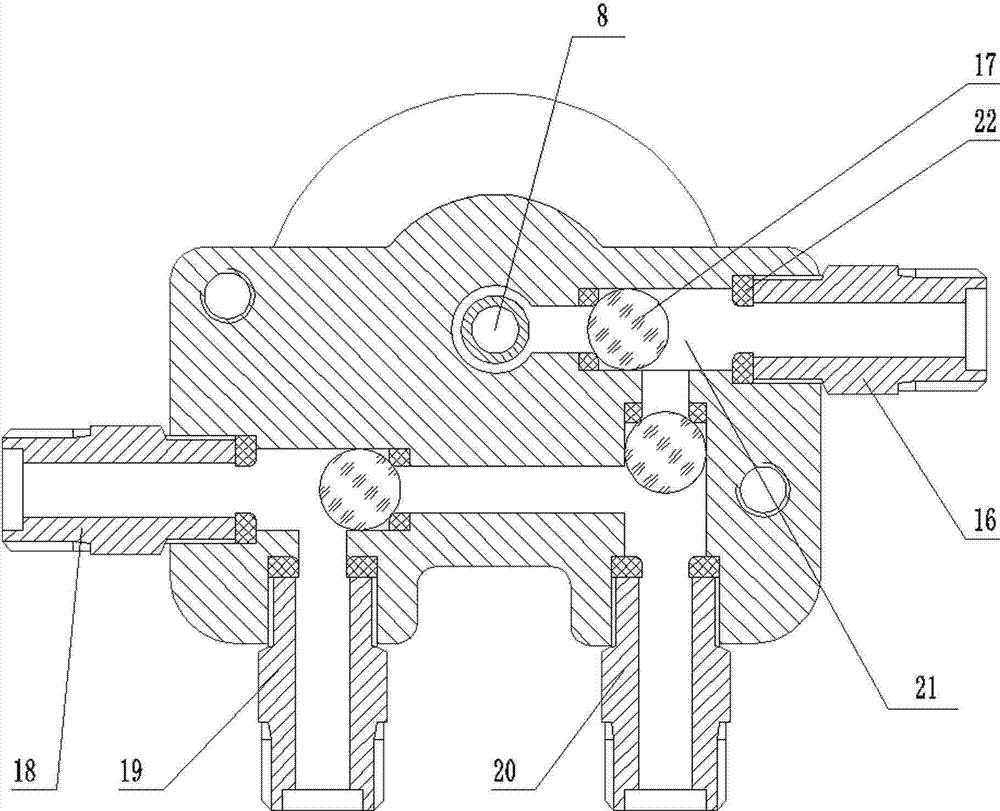

[0019] A kind of novel trailer control valve of the present invention is described in detail below in conjunction with accompanying drawing.

[0020] as attached figure 1 , figure 2 As shown, the novel trailer control valve includes a valve body 1 and a valve cover 12 installed on the lower side of the valve body 1. The upper and opposite sides of the valve body 1 are provided with an air inlet port 3 and an air outlet port 15. The valve body One side of the middle and lower part of 1 is provided with an air inlet and outlet 8. Corresponding to the side of the valve body 1, the middle and upper part of the other side of the valve body 1 is provided with an opening connected to the air outlet mechanism. The air outlet mechanism refers to three groups assembled in sequence. Two-way one-way valve 21, said two-way one-way valve 21 means that the openings on the opposite sides of the valve are air inlets, and the air outlet is arranged on the side wall, and is also movable inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com