Swing power tool

A technology of oscillating power tools and reciprocating oscillation, applied in the field of hand-held oscillating power tools, can solve the problems of enlarged machine size and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

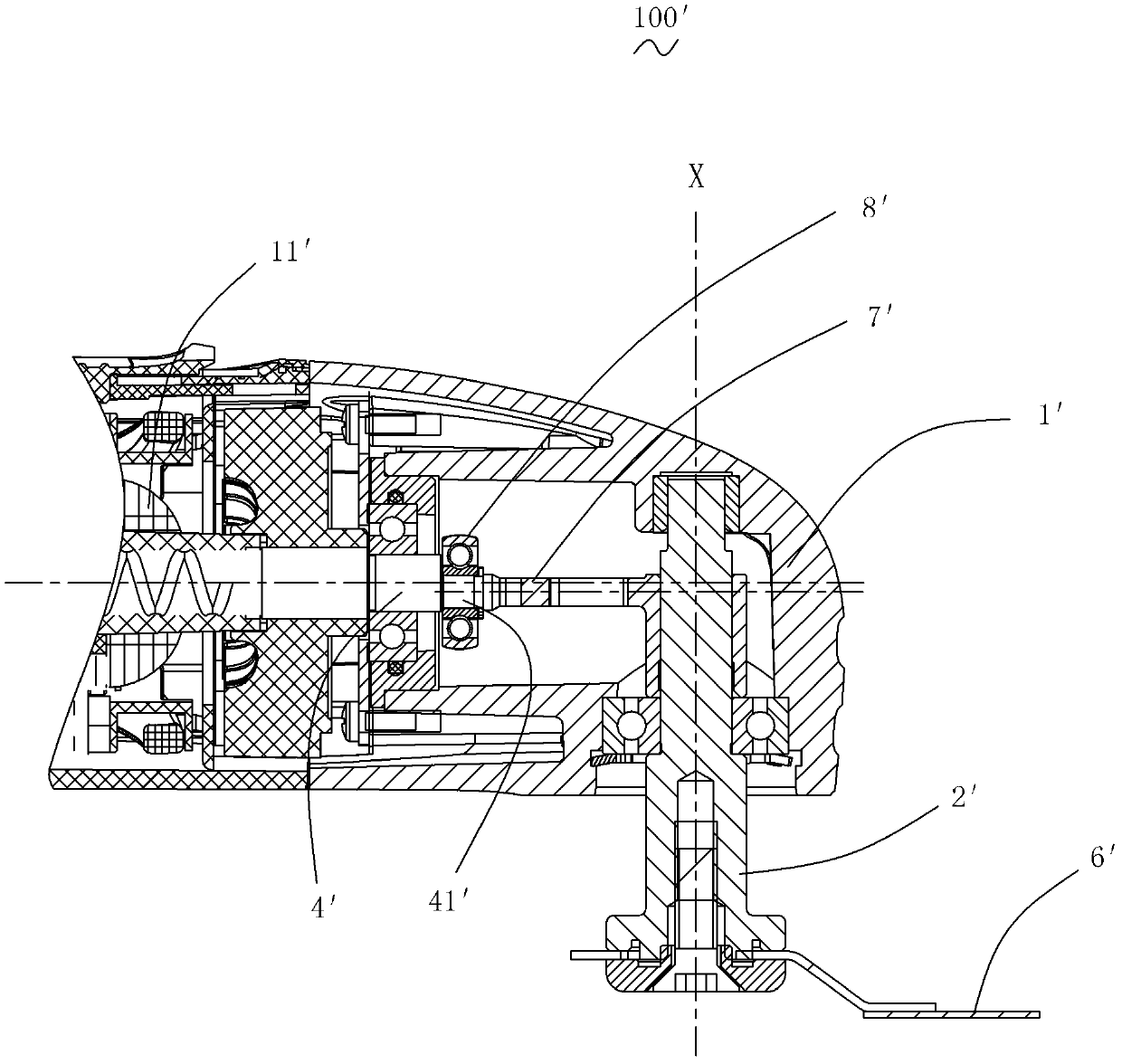

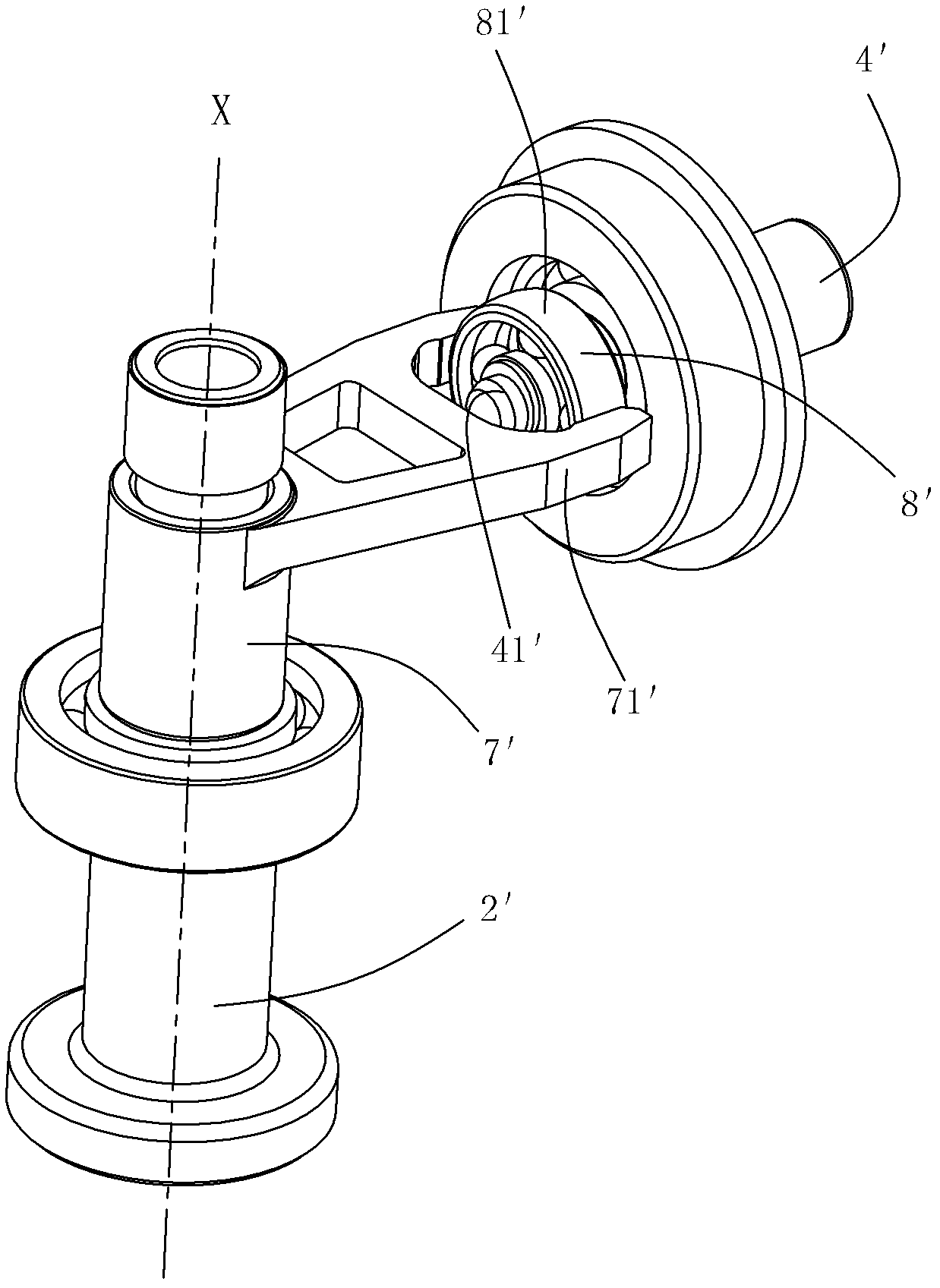

[0063] see image 3 , a swing power tool, specifically a multifunctional machine 100, which includes a longitudinally extending casing 10 connected to the front end of the casing 10 (with figure 1 The middle right side is defined as the head shell 11 of the front end) and the output shaft 12 extending from the head shell 11 . Wherein, a motor 101 is arranged inside the casing 10 , and a switch 102 is also arranged on the casing 10 to control the turning on or off of the motor 101 . A drive shaft 13 extends laterally from the motor 101 , and the drive shaft 13 rotates under the drive of the motor 101 . The head shell 11 is connected with the casing 10 and along the figure 1 The horizontal portion 111 is arranged in the horizontal direction and the vertical portion 112 extends substantially vertically downward from the end of the horizontal portion 111 . The output shaft 12 is arranged in the vertical direction, one end of which is installed in the head shell 11, and the othe...

specific Embodiment approach 2

[0082] In the above-mentioned first embodiment, the first stop surface on the first limiter of the transmission member and the second stop surface of the second limiter on the balance weight are both set to form a clip with respect to the axis of the eccentric shaft. horn. That is to say, both the first stopper of the transmission member and the second stopper of the second limiter have a certain taper, and both the first stopper surface and the second stopper surface form a certain slope along the axis of the eccentric shaft. Apparently, the first stop surface and the second stop surface can also be set as planes parallel to the axis of the eccentric shaft, which can also realize the adjustment of the eccentricity of the transmission member relative to the drive shaft. Combine below Figure 13 to Figure 15 , briefly describe the second embodiment of the present invention.

[0083] In this embodiment, the difference from the oscillating power tool 100 in the first embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com