Constant-tension wire moving control device for micro electrospark wire cutting and control method thereof

A technology of electric discharge wire and control device, which is applied in the direction of electrode manufacturing, circuit, manufacturing tools, etc., and can solve the problems of low machining accuracy and low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

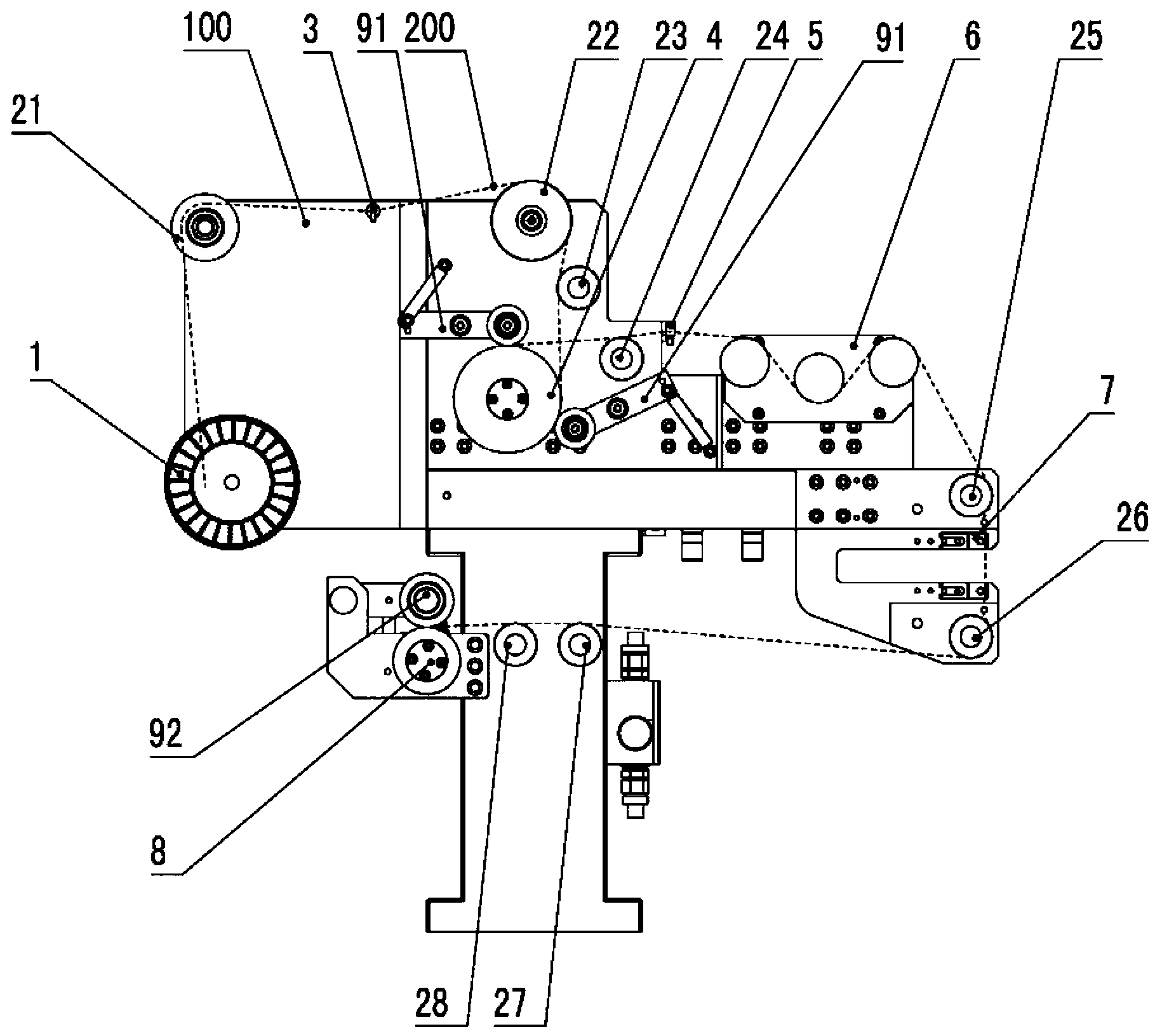

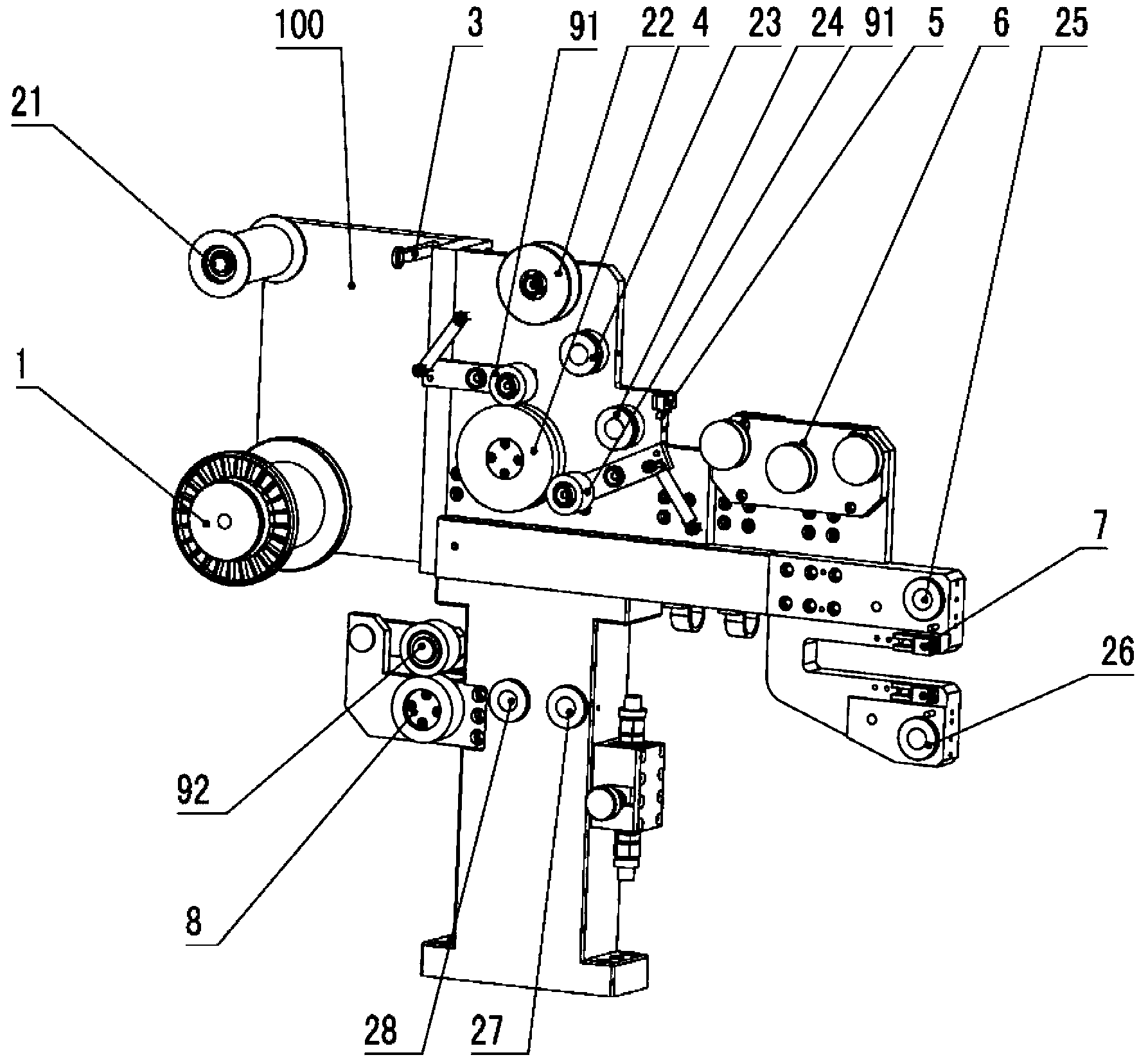

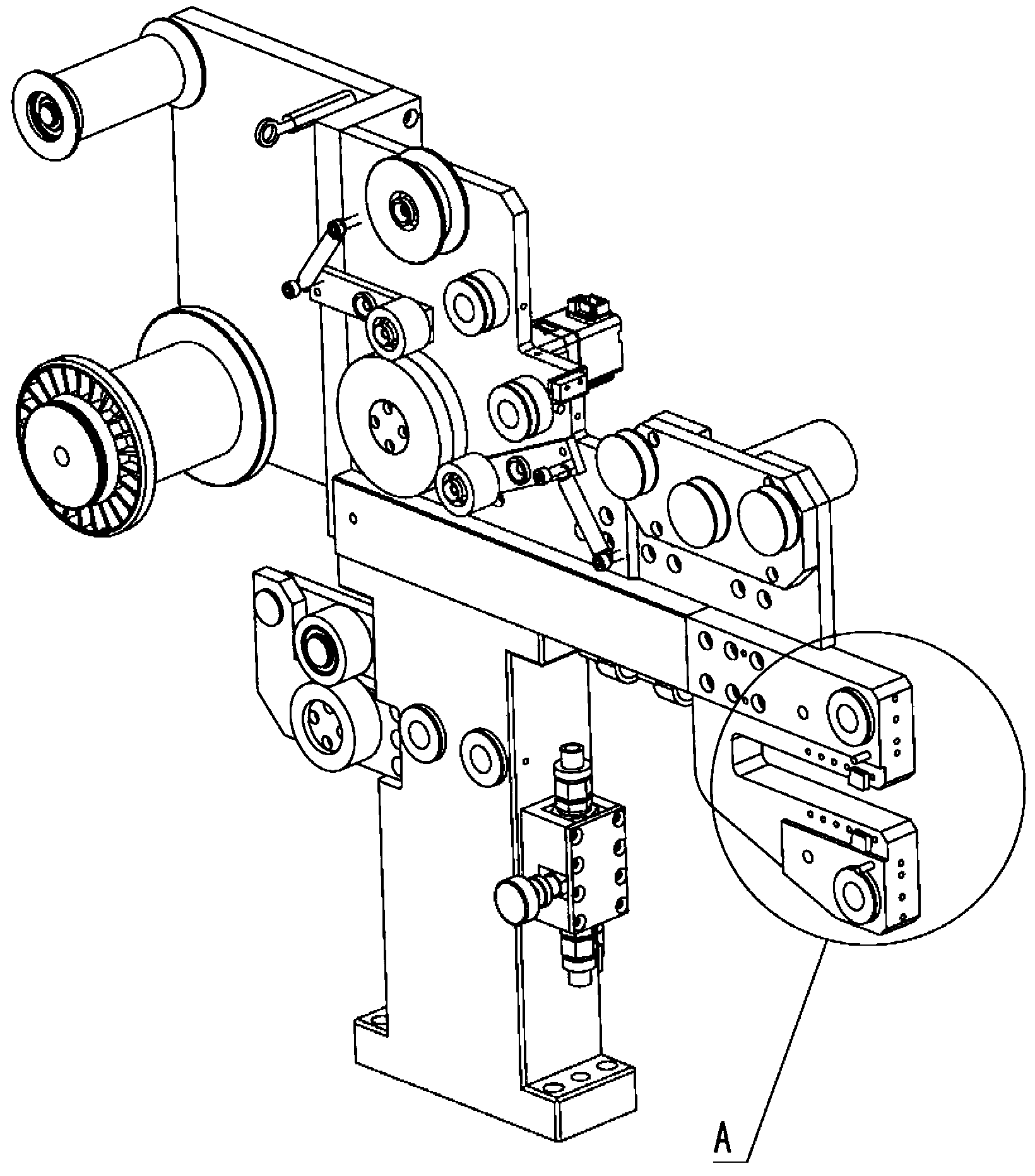

[0038] Figure 1 to Figure 8 The reference numerals in the figure are: rack 100; industrial computer 101; motion control card 102; first servo driver 103; first AC motor 104; second servo driver 105; second AC motor 106; Tube clamping device 1; first guide wheel 21; second guide wheel 22; third guide wheel 23; fourth guide wheel 24; fifth guide wheel 25; sixth guide wheel 26; seventh guide wheel 27; eighth guide wheel Guide wheel 28; guide ring 3; tension wheel 4; broken wire detection switch 5; tension sensor 6; guide 7; V-shaped block 71; first sub-block 711; second sub-block 712; ; The first pinch wheel mechanism 91 ; the second pinch wheel mechanism 92 .

[0039] Such as Figure 1 to Figure 6 As shown, a micro wire electric discharge cutting constant tension wire running control device includes a frame 100, a motion control card 102 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com