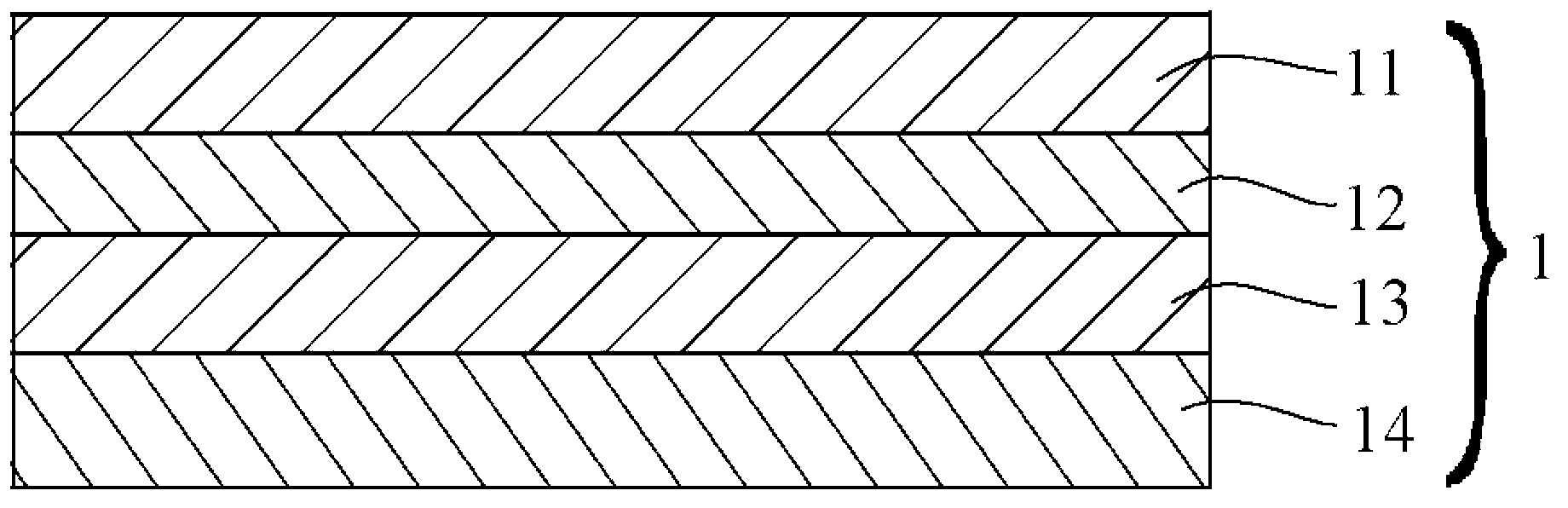

Multi-layer cooking appliance containing magnalium and preparation method of composite board of multi-layer cooking appliance

A technology for cooking utensils and magnesium-aluminum alloys, which is applied in the field of preparation of multilayer cooking utensils and their composite plates, can solve the problems of complex manufacturing processes of cooking utensils, and achieve good heat transfer, rapid heat transfer, and light weight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

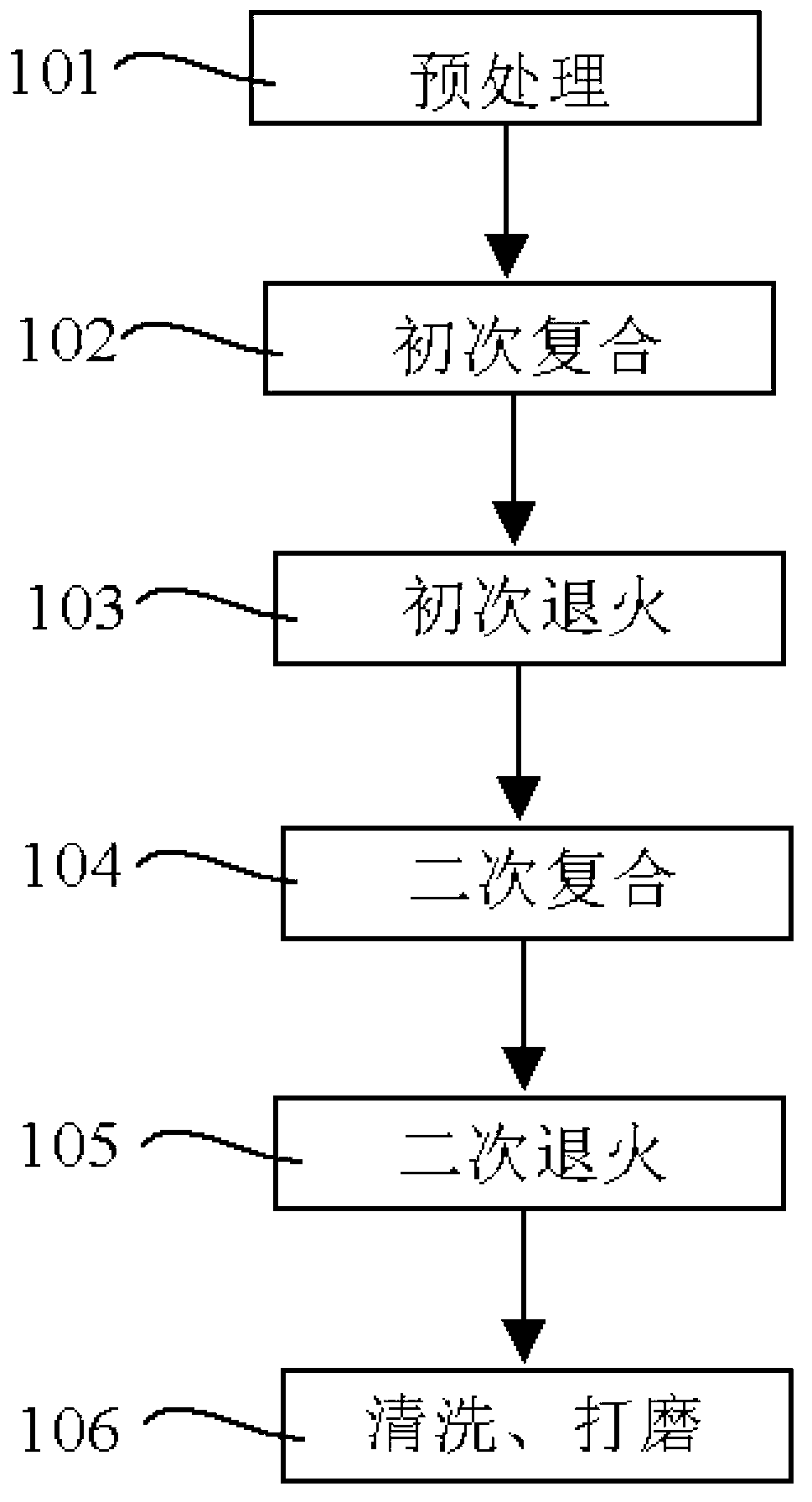

[0036] like figure 2 Shown, the preparation method of preparing above-mentioned composite board comprises the following steps:

[0037] Step 101, pretreatment, the pure aluminum plate, magnesium aluminum alloy plate, 304 stainless steel plate and 430 stainless steel plate are subjected to surface grinding treatment, so that the surface is smooth and smooth;

[0038] Step 102, initial compounding, rolling and compounding the pure aluminum plate and the magnesium-aluminum alloy plate to obtain a composite aluminum plate;

[0039] Step 103, primary annealing, annealing the composite aluminum plate in step 102 at a temperature of 550° C. for 30 minutes;

[0040] Step 104, secondary compounding, heating and rolling the 304 stainless steel plate and the 430 stainless steel plate respectively on both sides of the composite aluminum plate to obtain a composite plate, wherein the 430 stainless steel plate and the pure aluminum plate are rolled Pressing and laminating, the 304 stainl...

Embodiment 2

[0045] The preparation method for preparing the above-mentioned composite board comprises the following steps:

[0046] Different from Example 1,

[0047] In step 103, the annealing temperature is 600°C and the time is 2.5 hours.

[0048] In step 104, the temperature of heating, rolling and pressing is 200° C., the pressure is 2500 KN, and the plate moving speed is 2.5 m / min.

[0049] In step 105, the annealing temperature is 600°C and the time is 2 hours.

[0050] The composite plate produced by the above steps can adapt to various cold processes such as deep drawing, stretching, bulging, bending, punching, edge dragging, etc. without delamination, so that the cooking utensils still maintain their original firm bonding state.

Embodiment 3

[0052] The preparation method for preparing the above-mentioned composite board comprises the following steps:

[0053] Different from Example 1,

[0054] In step 103, the annealing temperature is 500° C. and the time is 30 minutes.

[0055] In step 104, the temperature of heating, rolling and pressing is 400° C., the pressure is 2500 KN, and the moving speed of the plate is 3 m / min.

[0056] In step 105, the annealing temperature is 400° C. and the time is 30 minutes.

[0057] The composite plate produced by the above steps can adapt to various cold processes such as deep drawing, stretching, bulging, bending, punching, edge dragging, etc. without delamination, so that the cooking utensils still maintain their original firm bonding state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com